PROPELLE

Fig. 2. Top bearing should begin to emerge,

turn joint over and finally remove with

fingers as shown in Fig.

3.

If necessary tap bearing race from inside

with small diameter bar, as shown in Fig.

4,

taking care not to damage the bearing race.

This operation will destroy the oil seal and

necessitate fitting replacement parts when

reassembling, keep joint in this position

whilst removing bearing race, so as to avoid

dropping the needle rollers.

Repeat the operation described in previous

paragraph for opposite bearing. The

splined sleeve yoke can now be removed as

shown in Fig.

5.

Rest the two exposed trunnions on wood or

lead blocks, then tap flange yoke with soft

hammer to remove the two remaining

bearing races.

Fig.

5

Removing the

Yoke.

6.

TO

EXAMINE

AND

CHECK

FOR

WEAR

The parts most likely to show signs of wear

after long usage are the bearing races and

spider trunnions. Should looseness in the

fit

of these parts, load markings, or dis-

tortion be observed, they must be renewed

complete, as no oversize journal bearing

races are provided. It is essential that

bearing races are a light drive fit in the yoke.

In the rare event of wear having taken place

in the yoke cross hole, the holes will most

certainly be oval, and such yokes must be

replaced.

In the case of wear of the cross holes in a

fixed yoke, which is part of the tubular

shaft assembly, only in cases of absolute

emergency should this be replaced by

welding

in

a new yoke. The normal pro-

cedure is to replace by a complete shaft

assembly. The other parts likely to show

signs of wear are the splines of the sleeve

yoke, or splined stub shaft.

A

total of

.004"

circumferential movement, measured on the

outside diameter of the spline, should not

be exceeded.

In the event of the splined stub shaft re-

quiring renewal this must be dealt with in

the same way as the fixed yoke,

i.e.,

a

replacement tubular shaft assembly fitted.

7.

TO ASSEMBLE

See that the trunnion assemblies are well

lubricated with one of the oils recom-

mended. Assemble needle rollers in bearing

recess, smearing the walls of the races with

vaseline, or lubricant, to retain the rollers

in place.

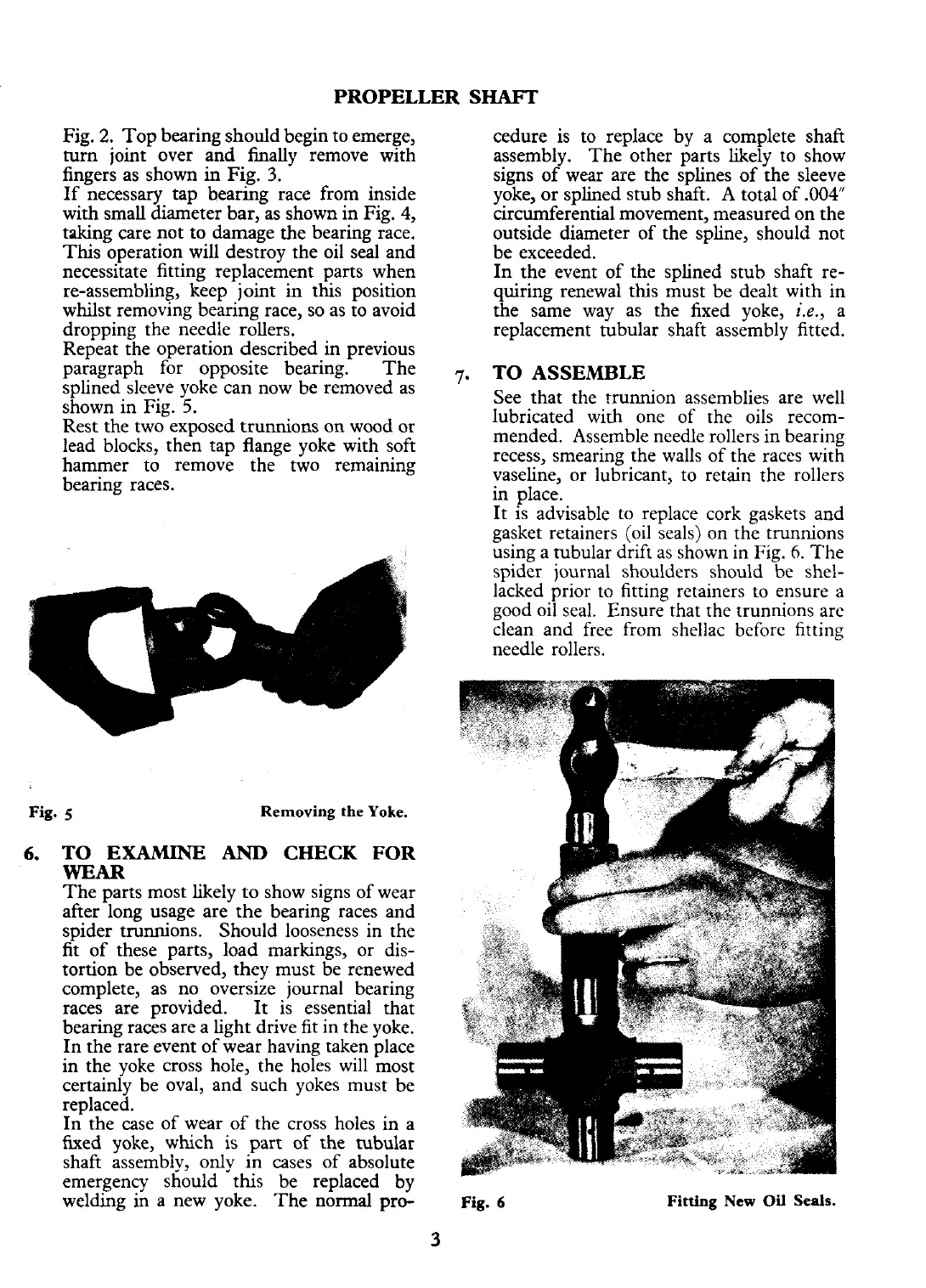

It is advisable to replace cork gaskets and

gasket retainers (oil seals) on the trunnions

using a tubular drift as shown in Fig.

6.

The

spider journal shoulders should be shel-

lacked prior to fitting retainers to ensure

a

good oil seal. Ensure that the trunnions are

clean and free from shellac before fitting

needle rollers.

Fig.

6

Fitting

New

Oil

Seals.

Loading...

Loading...