ELECTRICAL. EQUIPIMENT

(c) Belt Adjustment

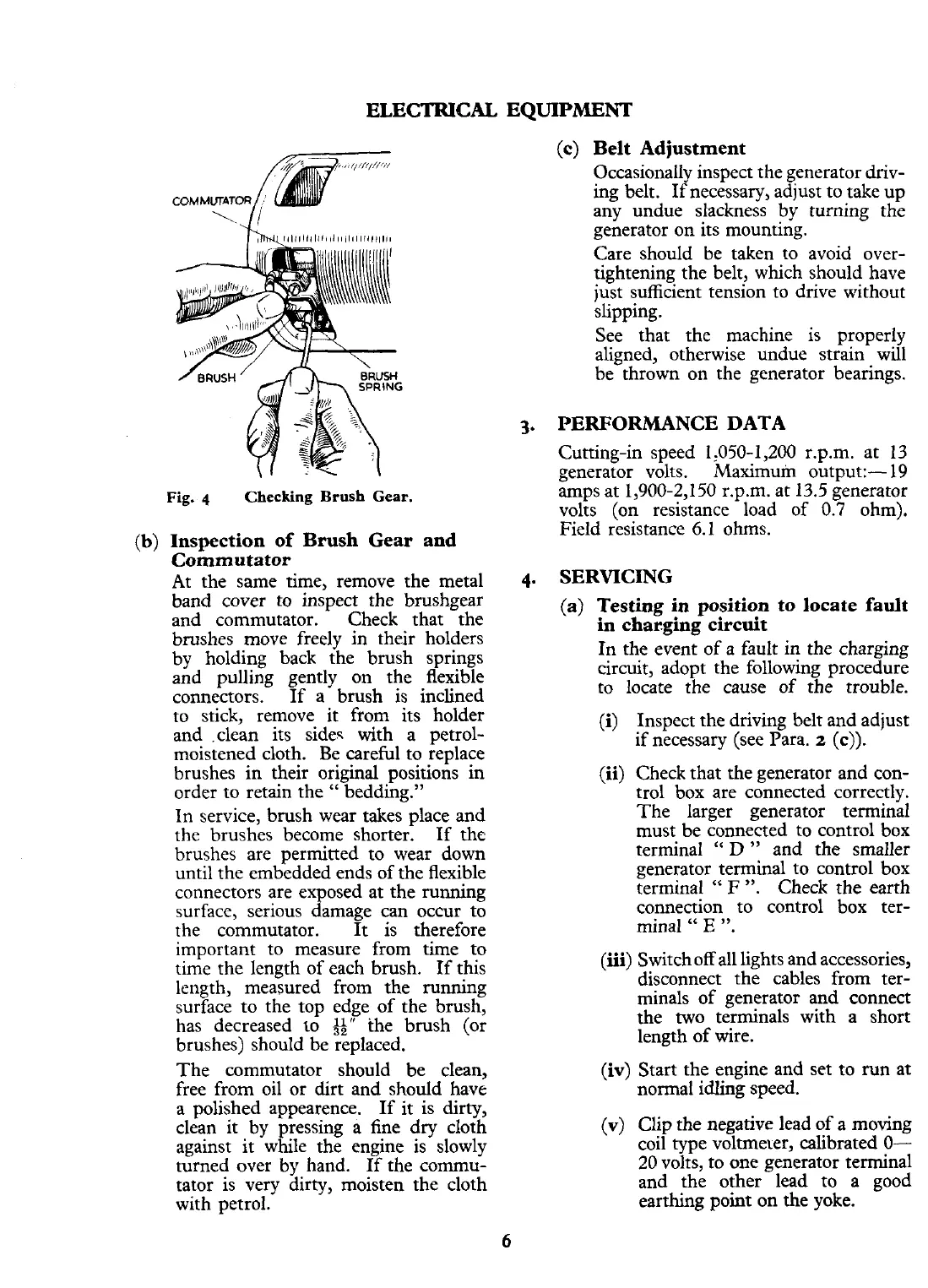

Fig.

q

Checking Brush Gear.

(b)

Inspection of Brush Gear and

Commutator

At the same time, remove the metal

4.

band cover to inspect the brushgear

and commutator. Check that the

brushes move freely in their holders

by holding back the brush springs

and pulling gently on the flexible

connectors. If a brush is inclined

to stick, remove it from its holder

and .clean its sides with a petrol-

moistened cloth. Be careful to replace

brushes in their original positions in

order to retain the

"

bedding."

In service, brush wear takes place and

the brushes become shorter. If the

brushes are permitted to wear down

until the embedded ends of the flexible

connectors are exposed at the running

surface, serious damage can occur to

the commutator.

It

is therefore

important to measure from time to

time the length of each brush. If this

length, measured from the running

surface to the top edge of the brush,

has decreased

10

g"

the brush (or

brushes) should be replaced.

The commutator should be clean,

free from oil or dirt and should have

a polished appearence. If it is

dirty,

clean it by pressing

a

fine dry cloth

against it while the engine is slowly

turned over by hand. If the commu-

tator is very dirty, moisten the cloth

with petrol.

Occasionally inspect the generator driv-

ing belt. If necessary, adjust to take up

any undue slackness by turning the

generator on its mounting.

Care should be taken to avoid

over-

tightening the belt, which should have

just sufficient tension to drive without

slipping.

See that the machine is properly

aligned, otherwise undue strain will

be thrown on the generator bearings.

PERFORMANCE

DATA

Cutting-in speed 1,050-1,200 r.p.m. at 13

generator volts. Maximuin output:- 19

amps at 1,900-2,150

r.p.m. at 13.5 generator

volts (on resistance load of 0.7 ohm).

Field resistance 6.1 ohms.

SERVICING

(a) Testing in position to locate fault

in charging circuit

In the event of a fault in the charging

circuit, adopt the following procedure

to locate the cause of the trouble.

(i)

Inspect the driving belt and adjust

if necessary (see Para.

2

(c)).

(ii)

Check that the generator and con-

trol box are connected correctly.

The larger generator terminal

must be connected to control box

terminal

"

D

"

and the smaller

generator terminal to control box

terminal

"

F

".

Check the earth

connection to control box ter-

minal

"

E ".

(iii)

Switchoff all lights and accessories,

disconnect the cables from ter-

minals of generator and connect

the two terminals with a short

length of wire.

(iv)

Start the engine and set to run at

normal idling speed.

(v)

Clip the negative lead of a moving

coil type voltrneler, calibrated

O-

20 volts, to one generator terminal

and the other lead to a good

earthing point on the yoke.

Loading...

Loading...