ELECTRICAL

EQUIPMENT

(vi) Gradually increase the engine

speed, when the voltmeter reading

should rise rapidly and without

fluctuation. Do not allow the

voltmeter reading to reach 20

volts and do not race the engine

in an attempt to increase the

voltage.

It

is sufficient to run

the generator up to a speed of

1,000

r.p.m.

If there is no reading, check

the brush gear as described in

(vii) below. If there is a low

reading of approximately

4-1

volt, the field winding may be

at fault (see Para.

4

(e)).

If there

is a reading of approximately

half the nominal voltage the arm-

ature winding may be at fault (see

Para.

4

(d)).

(vii)Remove the cover band and

examine the brushes and commu-

tator. Hold back each brush

spring and move the brush by

pulling gently on its flexible con-

nector. If the movement is

sluggish, remove the brush from

its holder and ease the sides

by lightly polishing on a smooth

file. Always replace the brush

in its original position. If a

brush has worn to

a"

in length

a new brush must be fitted and

bedded to the commutator.

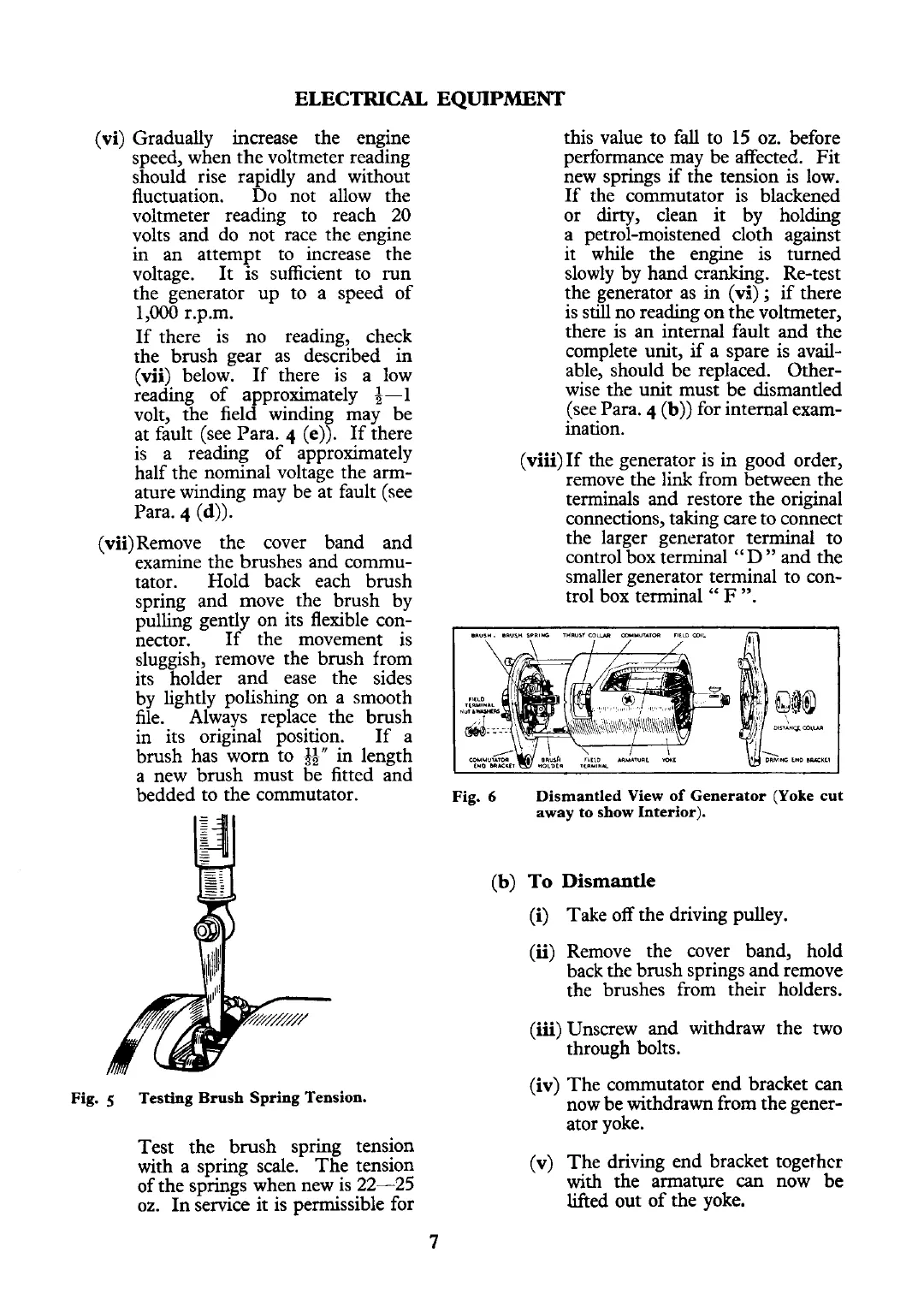

Fig.

5

Testing Brush Spring Tension.

Test the brush spring tension

with a spring scale. The tension

of the springs when new is 22-25

oz. In service it is permissible for

this value to fall to 15 oz. before

performance may be affected. Fit

new springs if the tension is low.

If the commutator is blackened

or

dirty,

clean it by holding

a petrol-moistened cloth against

it while the engine is turned

slowly by hand cranking. Re-test

the generator as in (vi)

;

if

there

is still no reading on the voltmeter,

there is an internal fault and the

complete unit, if a spare is avail-

able, should be replaced. Other-

wise the unit must be dismantled

(see Para.

4

(b))

for internal exam-

ination.

(viii) If the generator is in good order,

remove the link from between the

terminals and restore the original

connections, taking care to connect

the larger generator terminal to

control box terminal "D

"

and the

smaller generator terminal to con-

trol box terminal

"

F

".

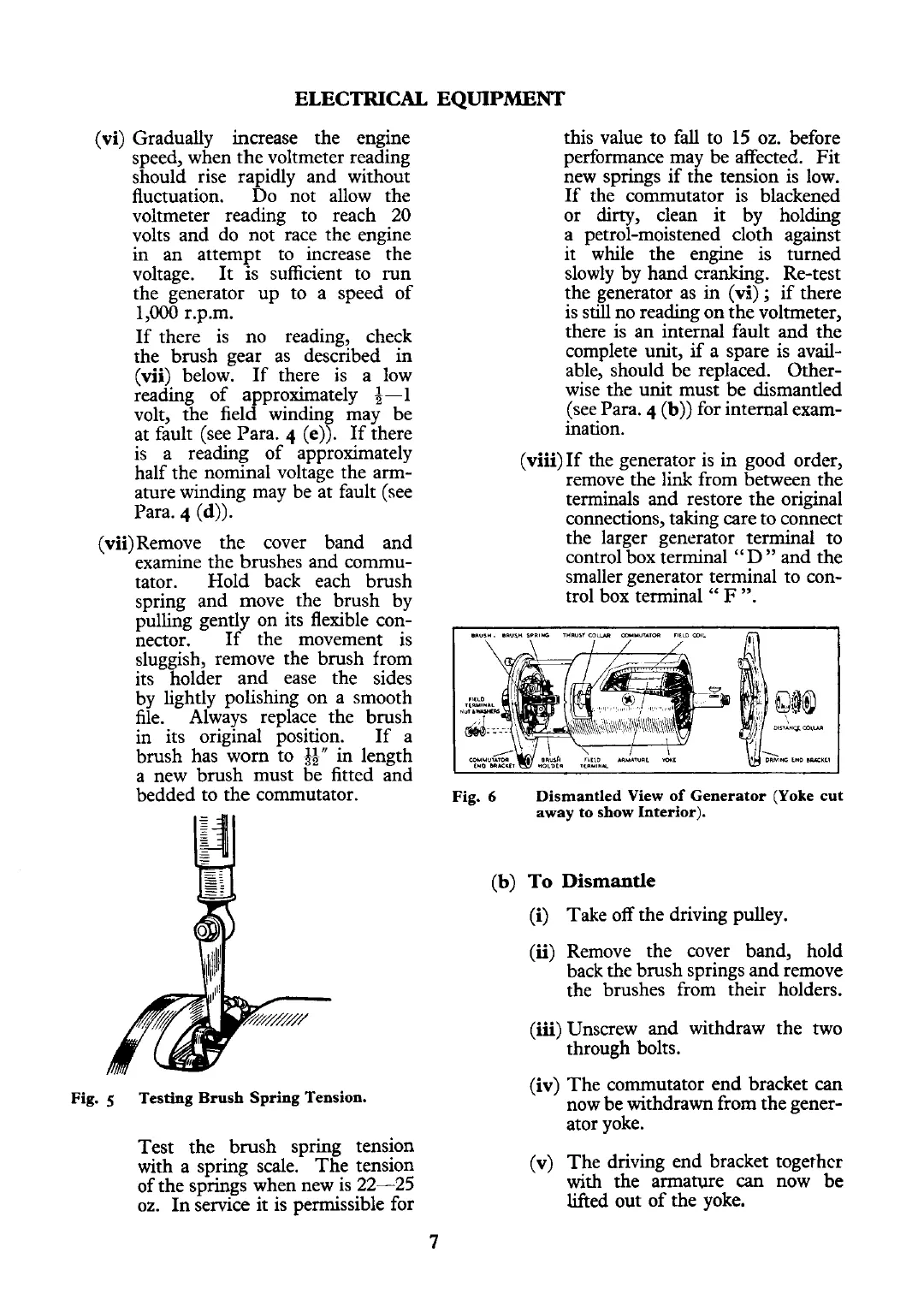

Fig.

6

Dismantled View of Generator (Yoke cut

away to show Interior).

(b)

To

Dismantle

(i)

Take off the driving pulley.

(ii) Remove the cover band, hold

back the brush springs and remove

the brushes from their holders.

(iii) Unscrew and withdraw the two

through bolts.

(iv) The commutator end bracket

can

now be withdrawn from the gener-

ator yoke.

(v) The driving end bracket

togerhcr

with the armature

can

now

be

lifted out of the yoke.

Loading...

Loading...