(vi)

The driving end bracket,

which

on removal from the yoke has

withdrawn with it the arma'iure

and armature shaft ball-bearing,

need not be separated

from the

shaft unless the bearing is sus-

pected and requires examination,

or the armature is to be replaced

;

in this event the armature should

be removed from the end bracket

by means of a hand press.

Commutator

A

commutator in good condition will

be smooth and free from pits or

burned spots. Clean the commutator

with a petrol-moistened cloth. If

this is ineffective, carefully polish

with a strip of he glass paper while

rotating the armature. To remedy a

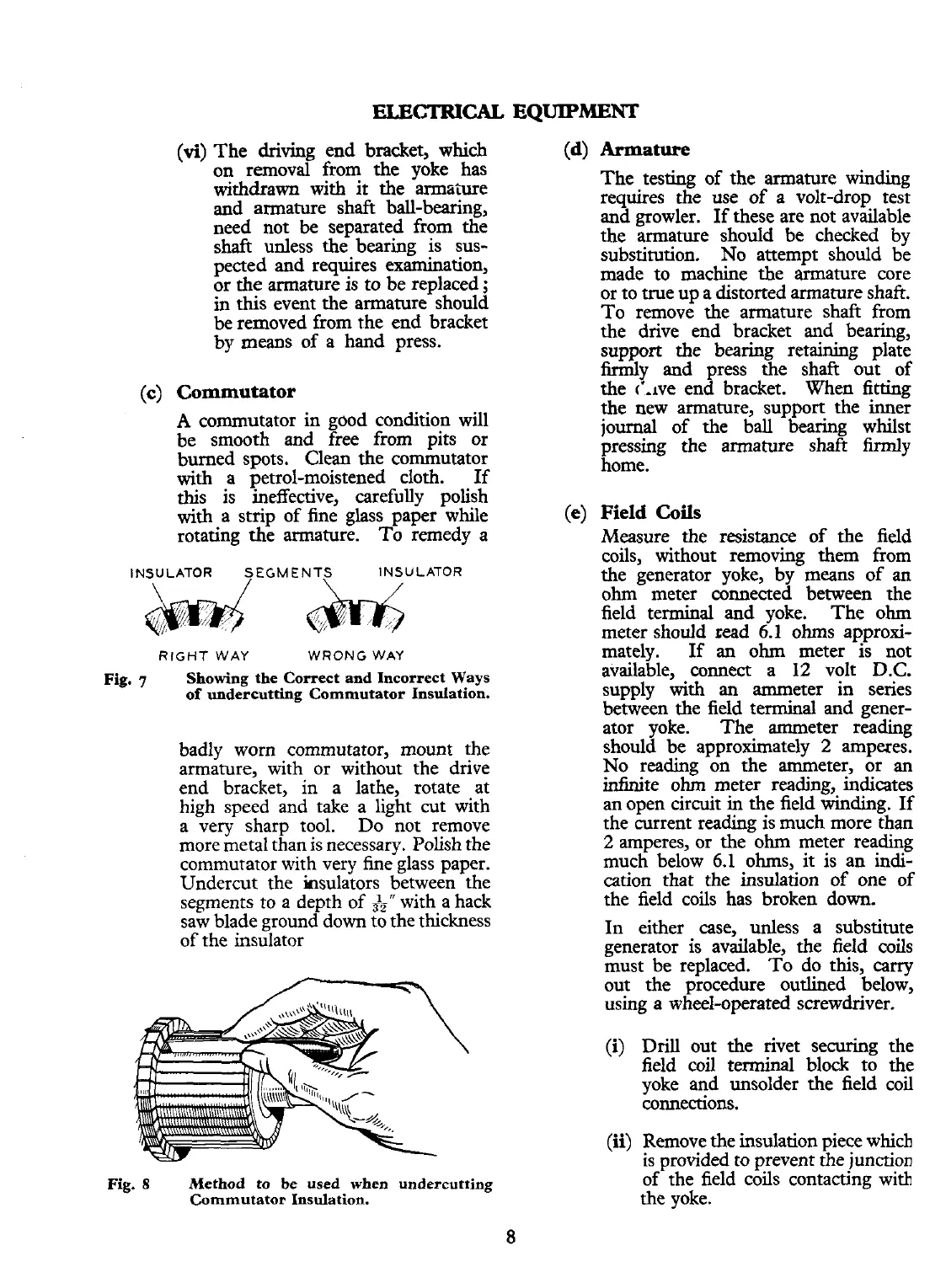

INSULATOR

SEGMENTS

INSULATOR

RIGHT

WAY WRONG

WAY

Fig.

7

Showing the Correct and Incorrect Ways

of undercutting Commutator Insulation.

badly worn commutator, mount the

armature, with or without the drive

end bracket, in a lathe, rotate at

high speed and take a light cut with

a very sharp tool. Do not remove

more metal than is necessary. Polish the

commutator with very fine glass paper.

Undercut the insulators between the

segments

to

a depth of

31,"

with a hack

saw blade ground down to the thickness

of the insulator

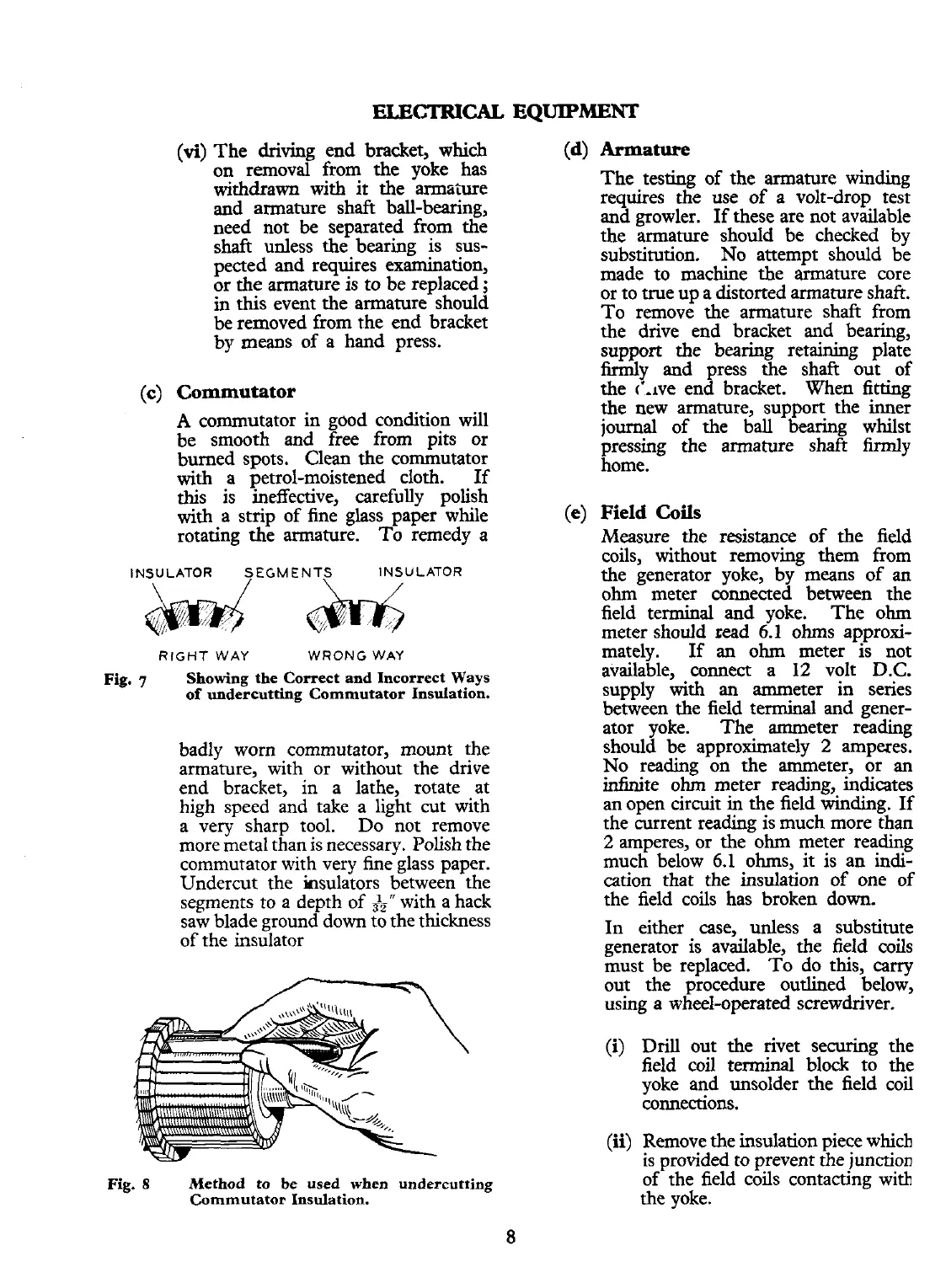

Fig.

8

Method to be used when undercutting

Commutator Insulation.

8

Armature

The testing of the armature winding

requires the use of a volt-drop test

and growler. If these are not available

the armature should be checked by

substitution. No attempt should be

made to machine the armature core

or to true up a distorted armature

shafc.

To remove the armature shaft from

the drive end bracket and bearing,

support the bearing retaining plate

firmly and press the shaft out of

the

c'.~ve end bracket. When fitting

the new armature, support the inner

journal of the ball bearing whilst

pressing the armature shaft firmly

home.

Field

Coils

Measure the resistance of the field

coils, without removing them from

the generator yoke, by means of an

ohm meter connected between the

field terminal and yoke. The ohm

meter should

read

6.1

ohms approxi-

mately. If an ohm meter is not

available, connect a 12 volt

D.C.

supply with an ammeter in series

between the field terminal and gener-

ator yoke. The ammeter reading

should be approximately

2

amperes.

No reading on the ammeter, or an

infinite ohm meter reading, indicates

an open circuit in the field winding. If

the current reading is much more than

2

amperes, or the ohm meter reading

much below

6.1

ohms, it is an indi-

cation that the insulation of one of

the field coils has broken down.

In either case, unless a substitute

generator is available, the field coils

must be replaced. To do this, carry

out the procedure outlined below,

using a

wheel-operated screwdriver.

(i)

Drill out the rivet securing the

field coil terminal block to the

yoke and unsolder the field coil

connections.

(ii)

Remove the insulation piece which

is

provided

to

prevent the junction

of the field coils contacting witb

the

yoke.

Loading...

Loading...