ELECTRICAL

EQUIPMENT

(iii) Mark the yoke and pole shoes

(0

Bearings

so that the latter

can

be fitted

Bearings which have worn to such an

in their original positions.

extent that

thw

will

allow side move-

(iv) Unscrew the pole shoe retaining

screws by means of the wheel-

operated screwdriver.

(v) Draw the pole shoes and coils

out of the yoke and lift off the

coils.

(vi) Fit the new field coils over the

pole shoes and place them in

position inside the yoke. Take

care to ensure that the taping of

the field coils is not trapped

between the pole shoes and the

yoke.

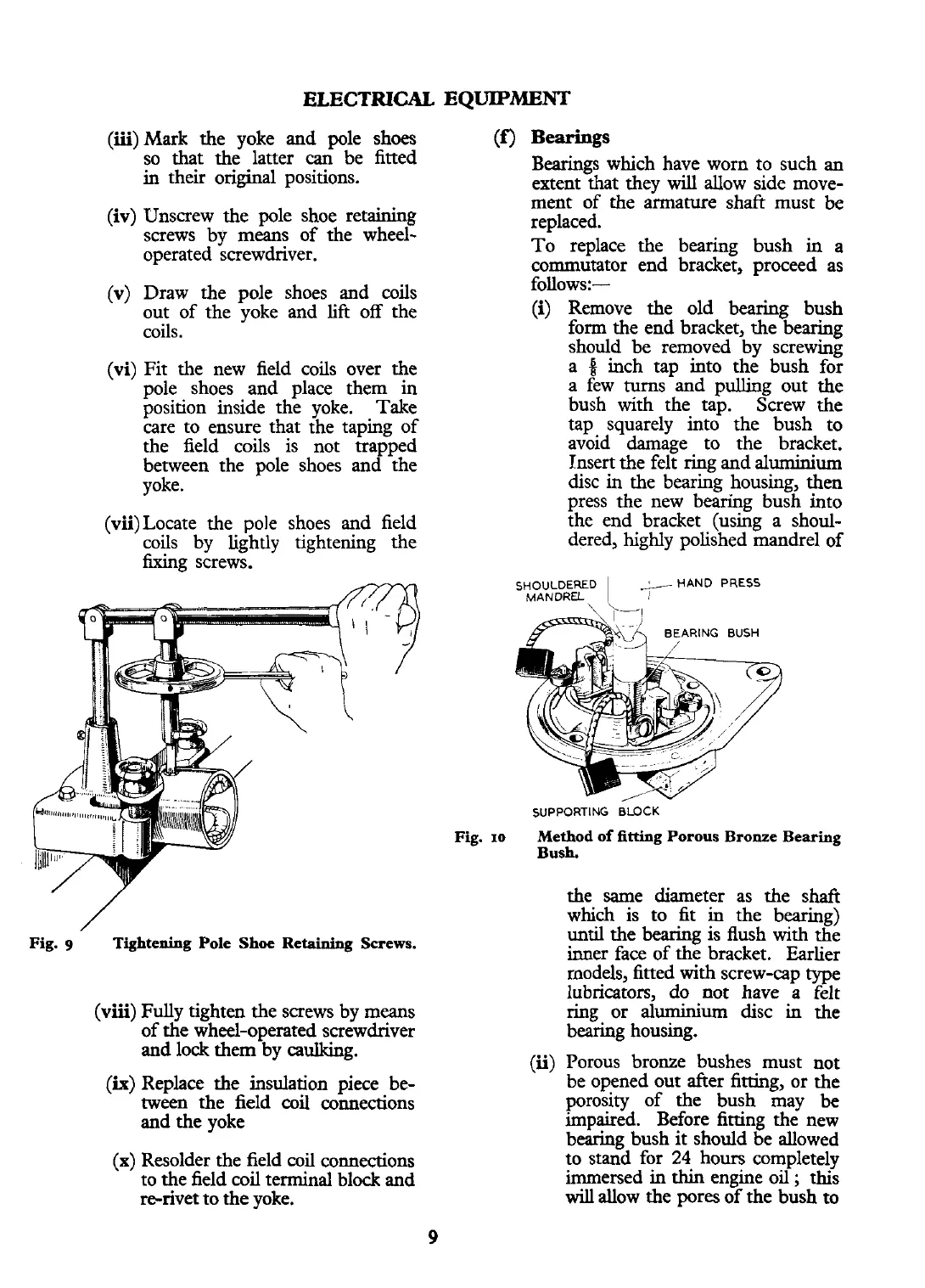

(vii)Locate the pole shoes and field

coils by lightly tightening the

fixing screws.

Fig.

9

Tightening Pole Shoe

Retaining

Screws.

(viii) Fully tighten the screws by means

of the wheel-operated screwdriver

and lock them by caulking.

(ix)

Replace the insulation piece be-

tween

the field

coil

connections

and the yoke

(X)

Resolder the field coil connections

to the field coil terminal block and

re-rivet to the yoke.

ment of the aknature shaft must be

replaced.

T;

replace the bearing bush

in

a

commutator end bracket, proceed as

follows:-

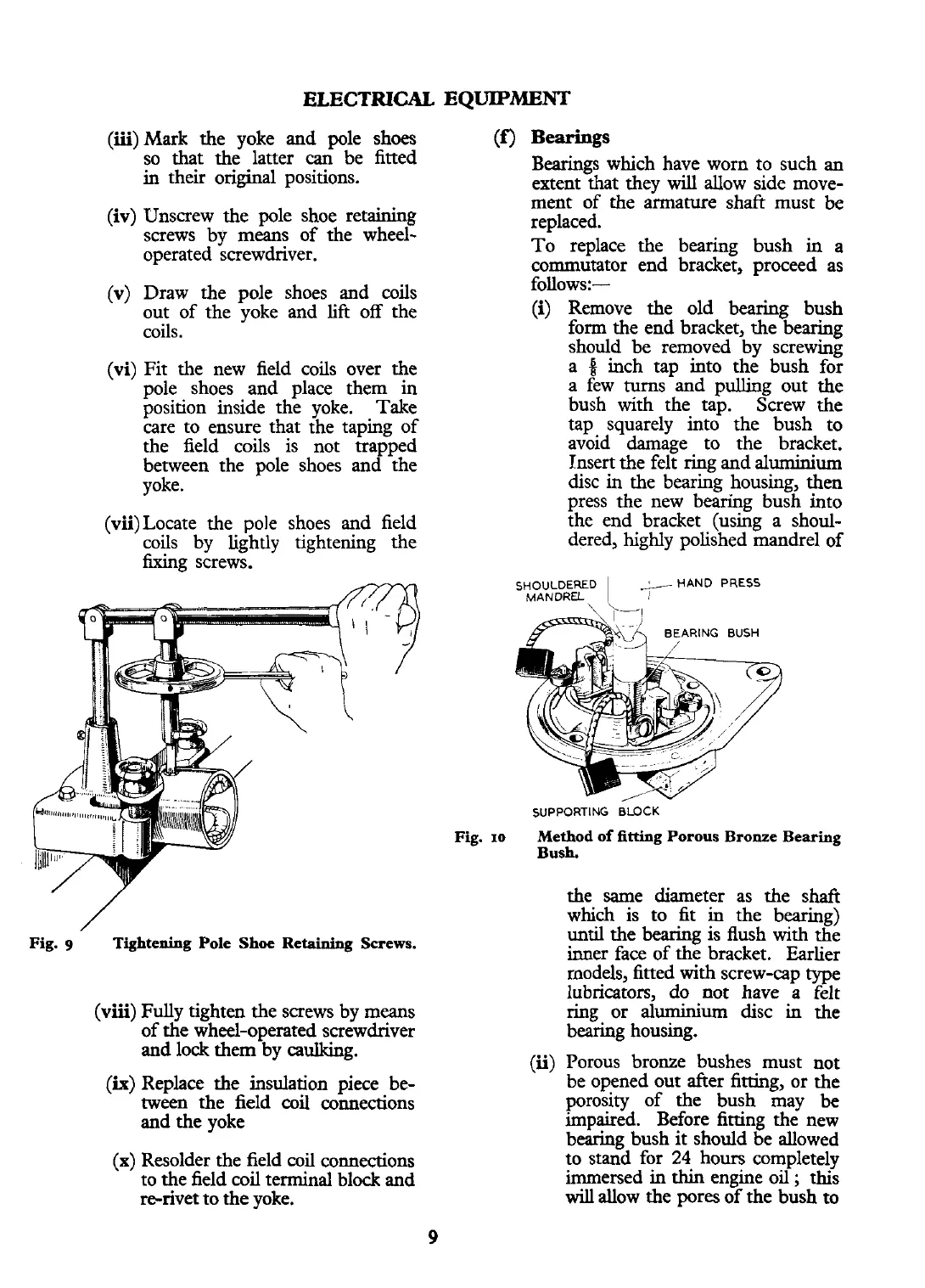

(i) Remove the old bearing bush

form the end bracket, the bearing

should be removed by screwing

a

Q

inch tap into the bush for

a few turns and pulling out the

bush with the tap. Screw the

tap squarely into the bush to

avoid damage to the bracket.

Insert the felt ring and

aluminium

disc in the bearing housing, then

press the new bearing bush into

the end bracket (using a shoul-

dered, highly polished mandrel of

SHOULDERED

MANDREL

1

YHAND

PRESS

,

SUPPORTING BLOCK

Fig.

10

Method of fitting Porous Bronze Bearing

Bush.

the same diameter as the shaft

which is to fit

in

the bearing)

until

the bearing is flush with the

inner face of the bracket. Earlier

models, fitted with screw-cap type

lubricators, do not have a felt

ring or

aluminium

disc

in

the

bearing housing.

(ii) Porous bronze bushes must not

be opened out after fitting, or the

porosity of the bush may be

impaired. Before

fitting the new

bearing bush it should be allowed

to stand for

24

hours completely

immersed in

thin

engine oil

;

this

will

allow the pores of the bush to

Loading...

Loading...