ELECTRICAL

be filled with lubricant. In cases of

extreme urgency, this period may

be shortened by heating the oil to

100

C.

for

2

hours, then allowing

to cool before removing the bear-

ing bush.

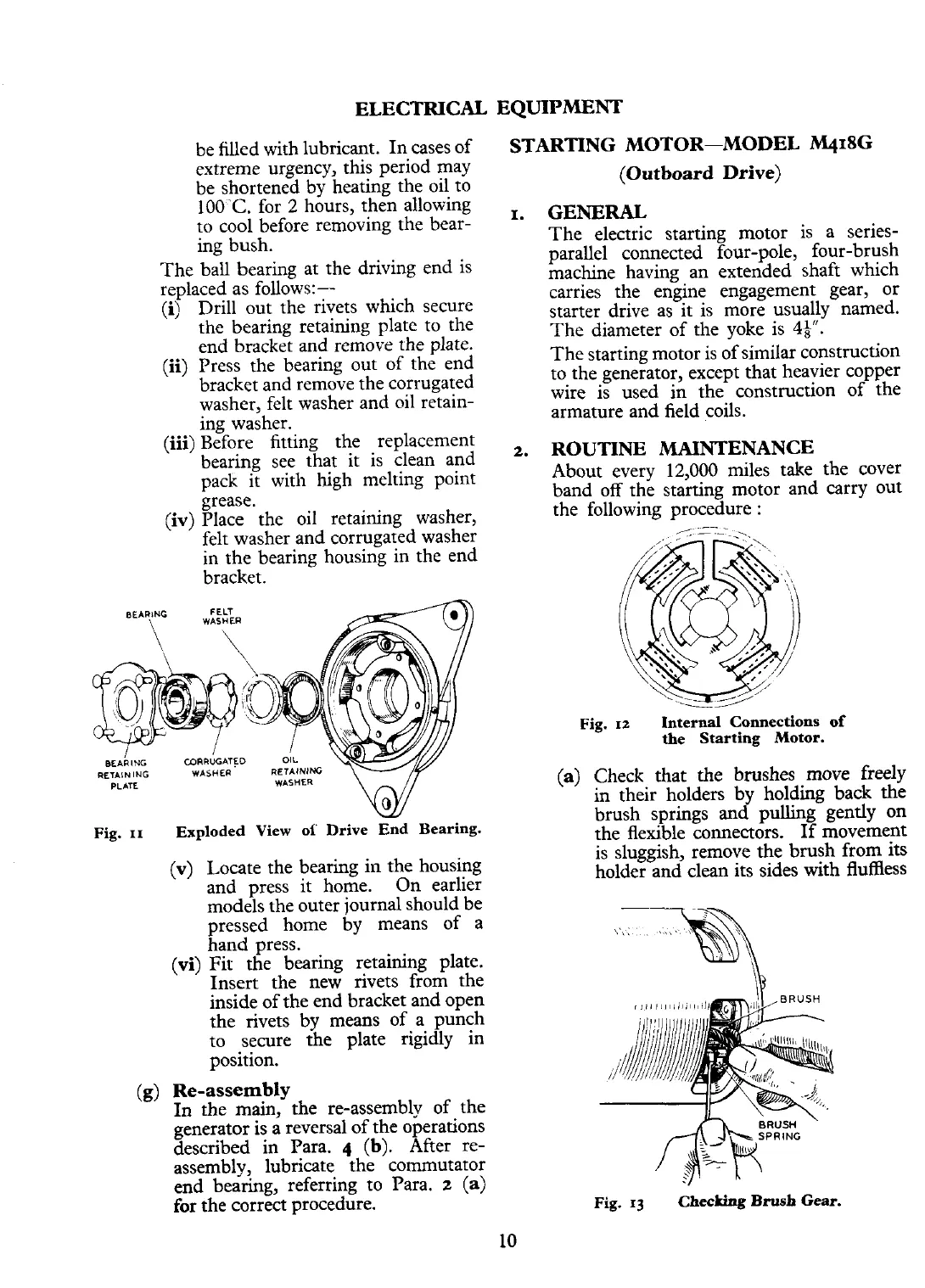

The ball bearing at the driving end is

replaced as follows:--

(i)

Drill out the rivets which secure

the bearing retaining plate to the

end bracket and remove the plate.

(ii)

Press the bearing out of the end

bracket and remove the corrugated

washer, felt washer and oil retain-

ing washer.

(iii)

Before fitting the replacement

bearing see that it is clean and

pack it with high melting point

grease.

fiv)

Place the oil retaining washer,

\-

,

felt washer and corrugated washer

in the bearing housing in the end

bracket.

Fig.

XI

Exploded View of Drive End Bearing.

(v)

Locate the bearing in the housing

and press it home.

On earlier

models the outer journal should be

pressed home by means of a

hand press.

(vi)

Fit the bearing retaining plate.

Insert the new rivets from the

inside of the end bracket and open

the rivets by means of a punch

to secure the plate rigidly in

position.

(g)

Re-assembly

In the main, the re-assembly of the

generator is a reversal of the operations

described in Para.

4

(b).

After re-

assembly, lubricate the commutator

end bearing, referring to Para.

2

(a)

for

the correct procedure.

lTIPMENT

'ARTING MOTOR-MODEL m18G

(Outboard Drive)

GENERAL

The electric starting motor is a series-

parallel connected four-pole, four-brush

machine having an extended shaft which

carries the engine engagement gear, or

starter drive as it is more usually named.

The diameter of the yoke is

46".

The starting motor is of similar construction

to the generator, except that heavier copper

wire is used in the construction of the

armature and field coils.

ROUTINE MAINTENANCE

About every 12,000 miles take the cover

band off the starting motor and carry out

the following procedure

:

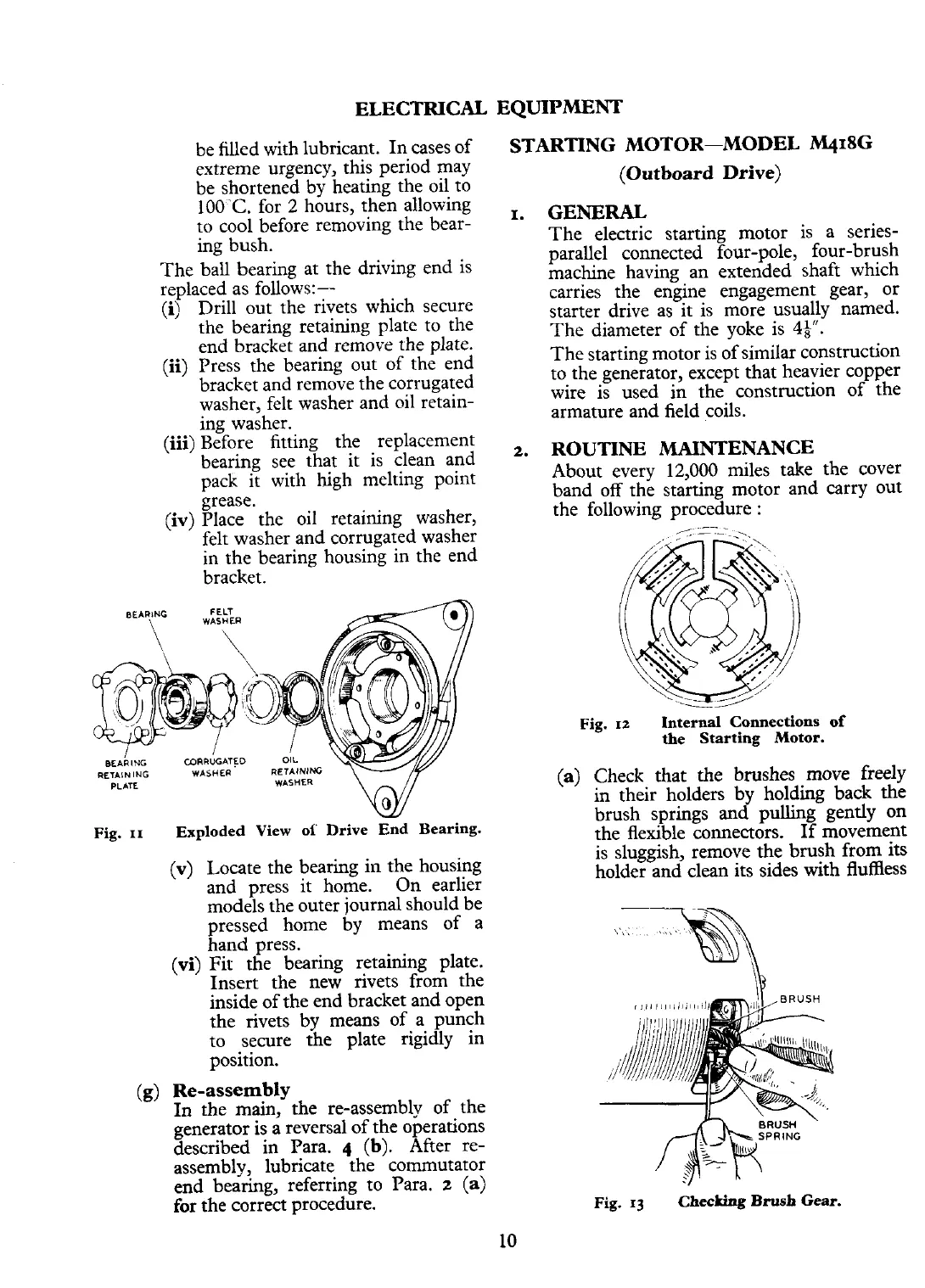

Fig.

12

Internal Connections

of

the Starting Motor.

(a)

Check that the brushes move freely

in their holders by holding back the

brush springs

and

pulling gently on

the flexible connectors. If movement

is sluggish, remove the brush from its

holder and clean its sides with fluffless

\

SPRING

Fig.

13

Checking

Brush

Gear.

Loading...

Loading...