ELECTRICAL

EQUIPMENT

(iv)

Fault

Diagnosis--(cont'd)

SYMPTOM

Speed, torque and current consumption low.

Speed and torque low, current consumption

hgh.

Speed and current consumption high, torque

low.

Armature does not rotate, no current con-

sumption.

Armature does not rotate, high current

consumption.

Excessive brush movement causing arcing at

commutator.

Excessive arcing at the commutator.

PROBABLE FAULT

High resistance in brushgear,

e.g.,

faulty

connections,

dirty

or burned commutator

causing bad brush contact.

Tight or worn bearings, bent shaft,

in-

suacient end play, armature fouling a pole

shoe, or cracked spigot on drive end bracket.

Short-circuited armature, earthed armature

or

short-circuited field coils.

Short-circuited field coils.

Open-circuited armature or field coils. If

the commutator is badly burned there may

be poor contact between brushes and com-

mutator.

Earthed field winding. Armature prevented

mechanically from rotating.

Low brush spring tension, worn or out-of-

round commutator.

"

Thrown

"

or high

segment on commutator.

Defective armature

windings

If any fault is indicated, the motor must be dismantled, see Para.

4

(c)

and a further

check made.

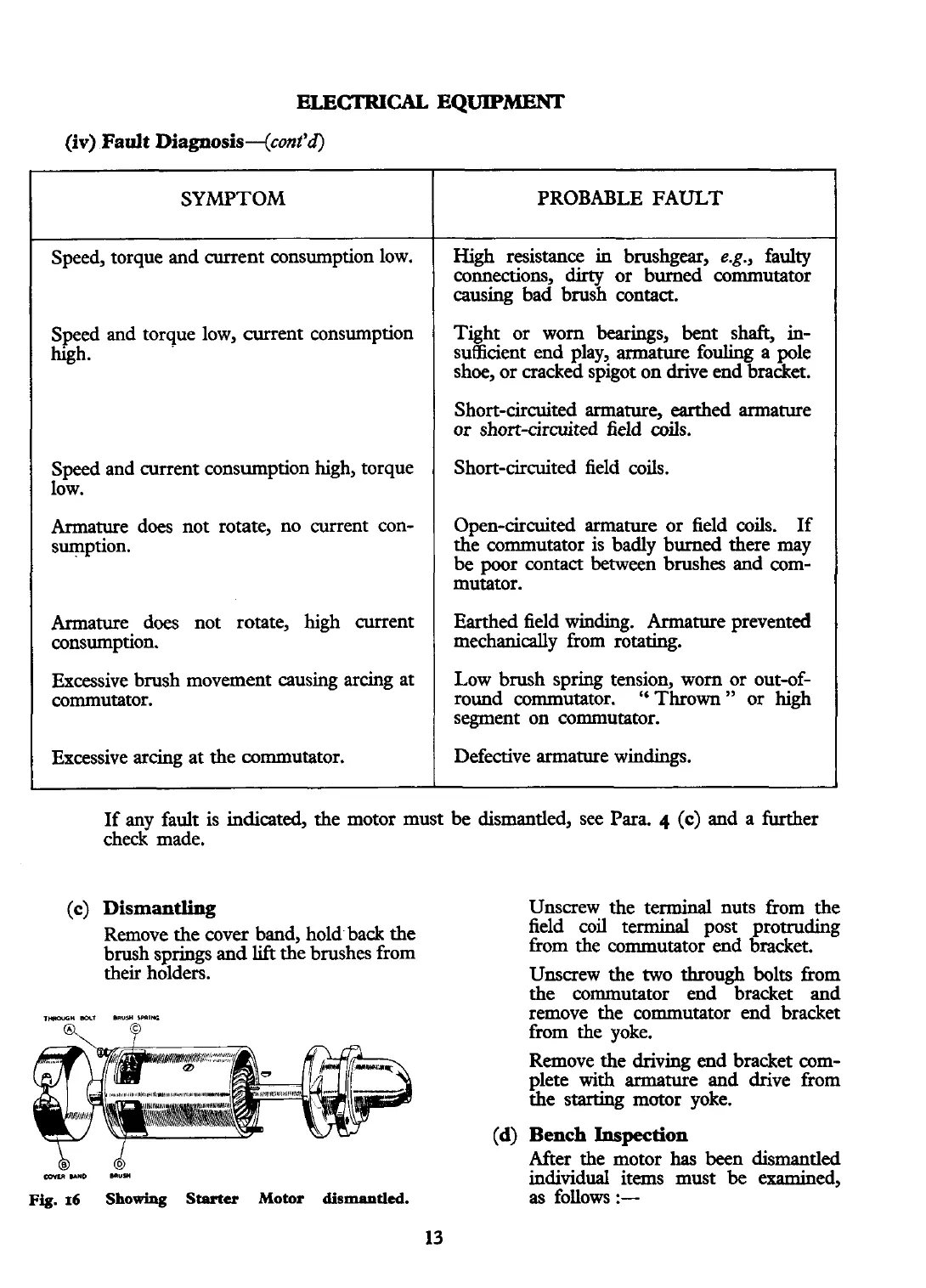

(c) Dismantling

Unscrew the terminal nuts from the

.

.

Remove the cover band, hold back the

field coil terminal post protruding

brush springs and

lift

the brushes from

from the commutator end bracket.

their holders.

Unscrew the two through bolts from

the commutator end bracket and

,-N

IXXI

UN*

S~I*C

remove the commutator end bracket

9

9

from the yoke.

Remove the driving end bracket com-

plete with armature and drive from

the starting motor yoke.

(d)

Bench Inspection

After the motor

has

been dismantled

m

WO

L"=

individual items must be examined,

Fig.

16

Showing Starter Motor

dismantled.

as

follows

:-

Loading...

Loading...