ELECTRICAL

EQUIPMENT

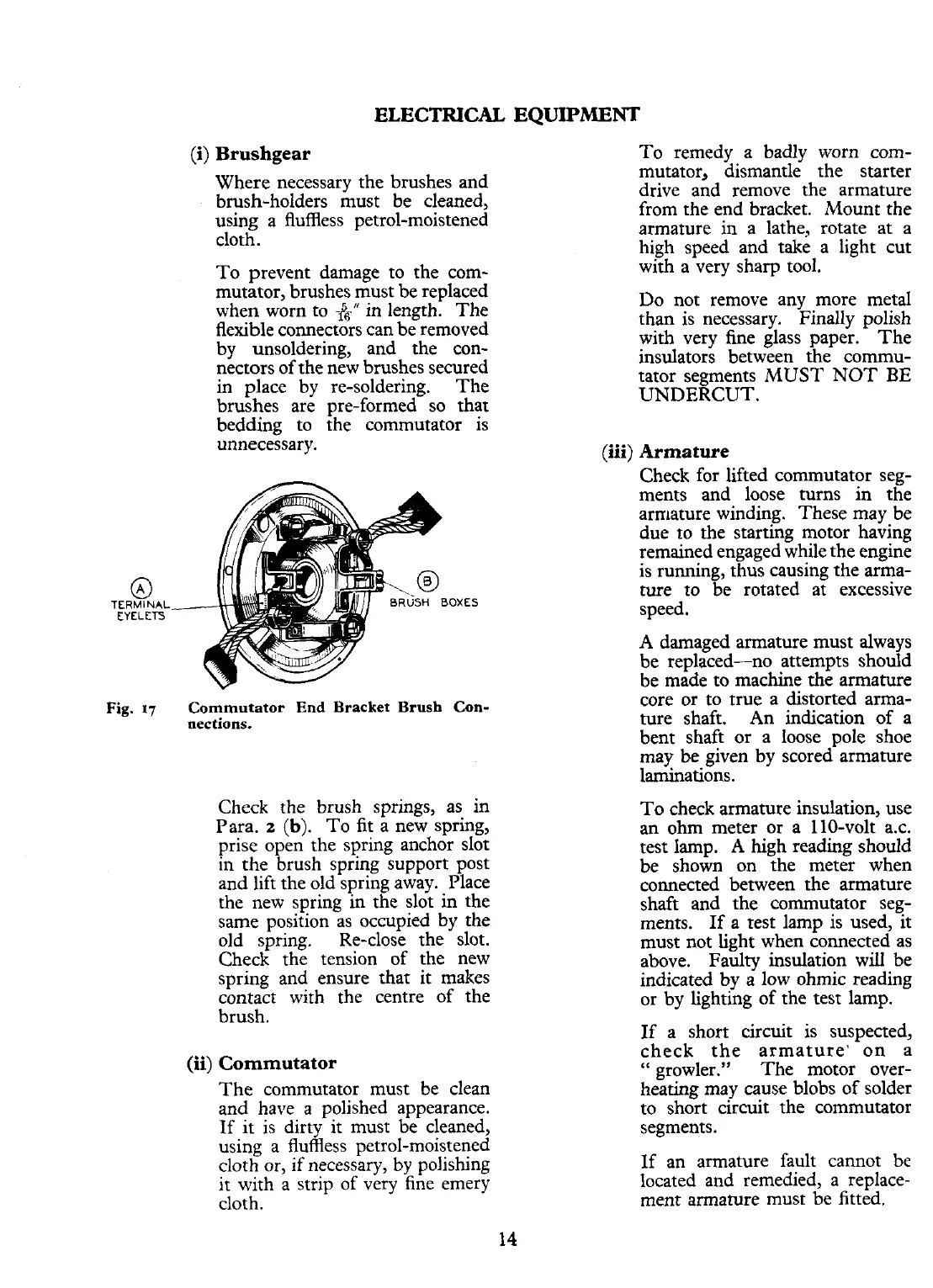

TERMINAL

EYELtrj

(i)

Brushgear

Where necessary the brushes and

brush-holders must be cleaned,

using a fluffless petrol-moistened

cloth.

To prevent damage to the com-

mutator, brushes must be replaced

when worn to

-fgn

in length. The

flexible connectors can be removed

by unsoldering, and the con-

nectors of the new brushes secured

in place by re-soldering. The

brushes are vre-formed so that

bedding to

;he commutator is

unnecessary.

Fig.

17

Commutator

End

Bracket Brush

Con-

nections.

Check the brush springs, as in

Para.

2

(b).

To fit a new spring,

prise open the spring anchor slot

in the brush spring support post

and lift the old spring away. Place

the new spring in the slot in the

same position as occupied by the

old spring. Re-close the slot.

Check the tension of the new

spring and ensure that it makes

contact with the centre of the

brush.

(ii)

Commutator

The commutator must be clean

and have a polished appearance.

If it is dirty it must be cleaned,

using a fluffless petrol-moistened

cloth

or,

if necessary, by polishing

it with

a

strip of very fine emery

cloth.

To remedy a badly worn com-

mutator, dismantle the starter

drive and remove the armature

from the end bracket.

Mount the

armature in a lathe, rotate at a

high speed and take a light cut

with a very sharp tool.

Do not remove any more metal

than is necessary. Finally polish

with very fine glass paper.

The

insulators between the

comrnu-

tator segments MUST NOT

BE

UNDERCUT.

(iii)

Armature

Check for lifted commutator seg-

ments and loose turns in the

armature winding. These may be

due to the starting motor having

remained engaged while the engine

is running, thus causing the arma-

ture to be rotated at excessive

speed.

A damaged armature must always

be replaced-no attempts should

be made to machine the armature

core or to true a distorted arma-

ture shaft. An indication of a

bent shaft or a loose pole shoe

may be given by scored armature

laminations.

To check armature insulation, use

an ohm meter or a 110-volt

a.c.

test lamp. A high reading should

be shown on the meter when

connected between the armature

shaft and the commutator seg-

ments. If a test lamp is used, it

must not light when connected as

above. Faulty insulation will be

indicated by a low ohmic reading

or by lighting of the test lamp.

If a short circuit is suspected,

check the armature' on a

"

growler." The motor over-

heating may cause blobs of solder

to short circuit the commutator

segments.

If an armature fault cannot be

located and remedied, a replace-

ment armature must be fitted.

Loading...

Loading...