ELECTRICAL EQUIPMENT

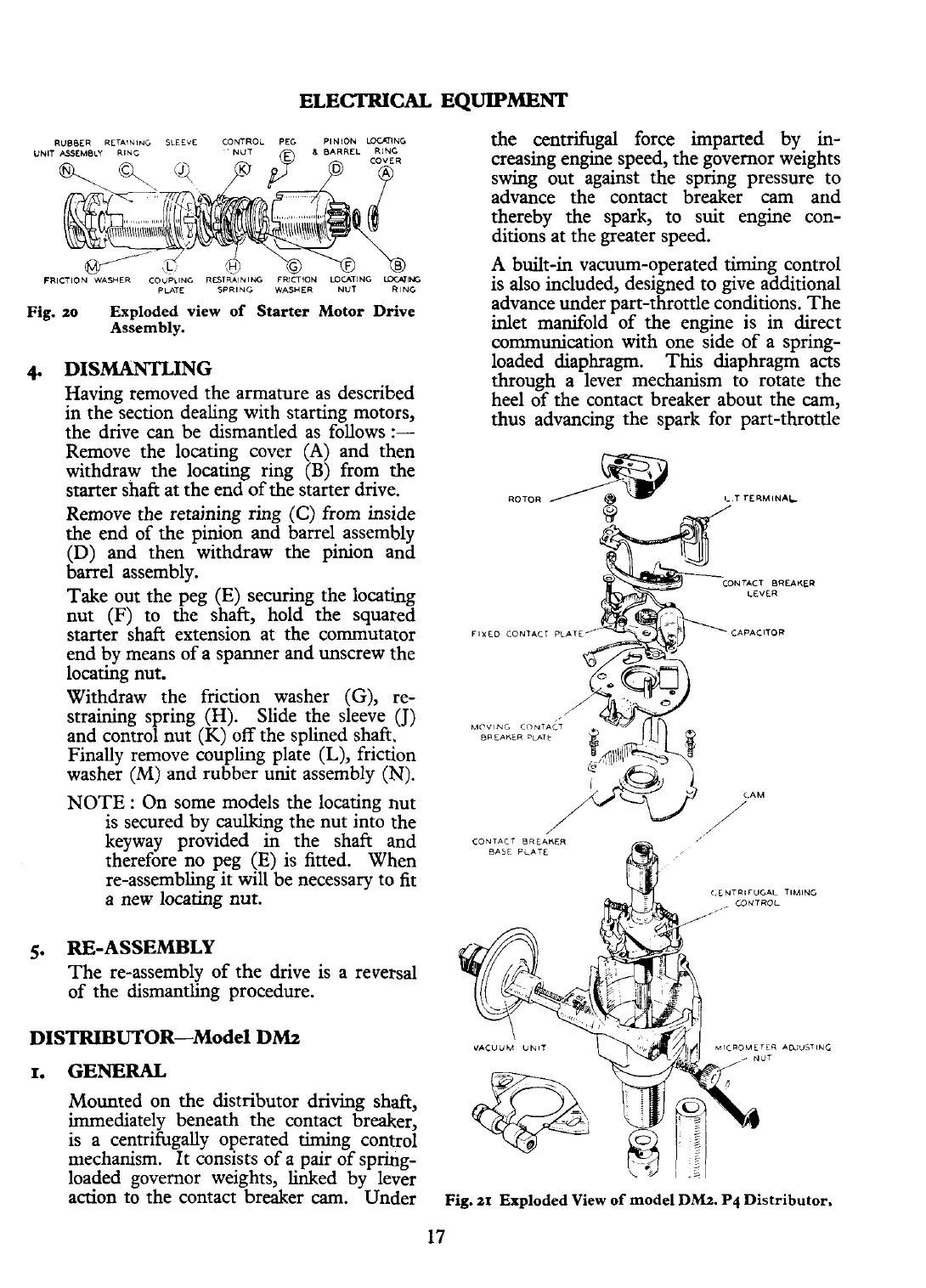

RUBBER RLTAINING SLEEVE CONTROL PEG PINION WING

UNIT

the centrifugal force imparted by in-

creasing engine speed, the governor weights

swing out against the spring pressure to

advance the contact breaker cam and

thereby the spark, to suit engine con-

ditions at the greater speed.

A

built-in vacuum-operated timing control

FRICTION WASHER COVPilNG

RDTRMNIffi

FRICTION WUTING UKAIffi

?LATE

SPRING

W~SHER

NUT

RING

is also included, designed to give additional

Fig.

zo

Exploded view of Starter Motor Drive

advance under part-throttle conditions. The

Assembly.

inlet manifold of the engine is in direct

communication with one side of a spring-

4.

DISMANTLING

loaded diaphragm. This diaphragm acts

through a lever mechanism to rotate the

Having removed the armature as described

heel of the contact breaker about the cam,

in the section dealing with starting motors,

thus advancing the spark for part-throttle

the drive

can

be dismantled as follows

:-

Remove the locating cover

(A)

and then

withdraw the locating ring

(B)

from the

starter shaft at the end of the starter drive.

ROTOR

3

@

8.

T TERMINAL

Remove the retaining ring

(C)

from inside

the end of the pinion and barrel assembly

(D)

and then withdraw the pinion and

barrel assembly.

NTACT BREAKER

Take out the peg (E) securing the locating

nut (F) to the shaft, hold the squared

starter shaft extension at the commutator

FIXED

CONTACT

PLATE'

end by means of a spanner and unscrew the

locating nut.

Withdraw the friction washer

(G),

re-

straining spring (H). Slide the sleeve

(J)

MCVNG

CONTACT

and control nut

(K)

off the splined shaft.

BREAnt~

bin,t

Finally remove coupling plate

(L),

friction

washer

(M)

and rubber unit assembly

(N).

NOTE

:

On some models the locating nut

is secured by caulking the nut into the

keyway provided in the shaft and

CONTACT BRE

BASE PLATE

therefore no peg (E) is fitted. When

re-assembling it will be necessary to fit

a new locating nut.

<.LNTRIrUGAL TlMlNC

5.

RE-ASSEMBLY

The re-assembly of the drive is a reversal

of the dismantling procedure.

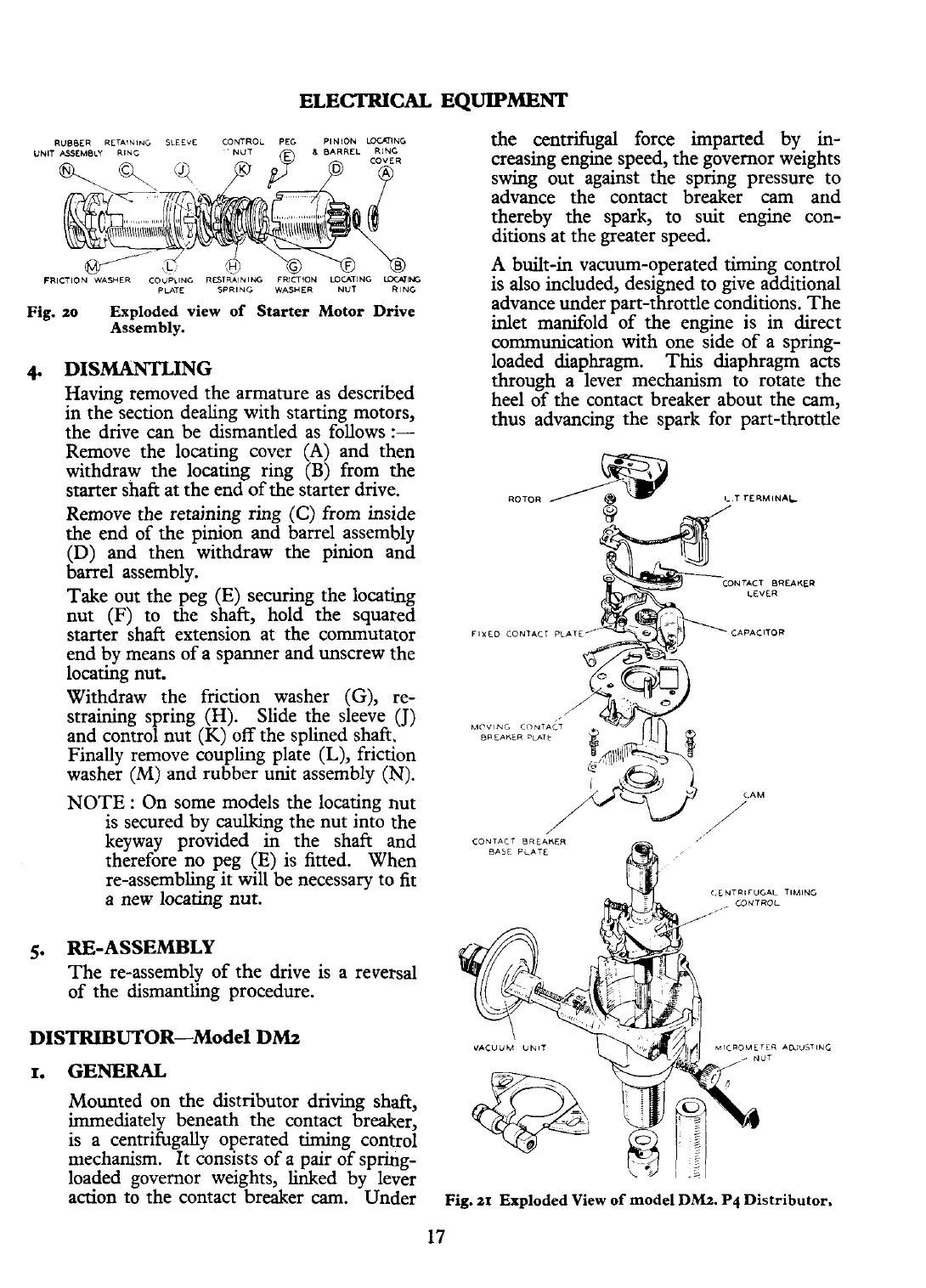

DISTRIBUTOR-Model DM2

VACUUM

UNIT

I.

GENERAL

Mounted on the distributor driving shaft,

immediately beneath the contact breaker,

is a centrifugally operated timing control

mechanism. It consists of a pair of

spring-

loaded governor weights, linked by lever

action to the Contact breaker

cam.

Under

Fig.

zr

Exploded View of model DM2.

P4

Distributor.

17

Loading...

Loading...