ELECTRICAL EQUIPMENT

operating conditions. There is also a

micrometer adjustment by means of which

fine alterations in timing can be made to

allow for changes in

running conditions,

e.g.,

state of carbonisation, change of fuel,

etc.

A

completely sealed metallised paper

capacitor is utilised. This has the property

of being self-healing

;

should the capacitor

break down, the metallic

film

around the

point of rupture is vaporised away by the

heat of the spark, so preventing a per-

manent short circuit. Capacitor failure

will be found to be most infrequent.

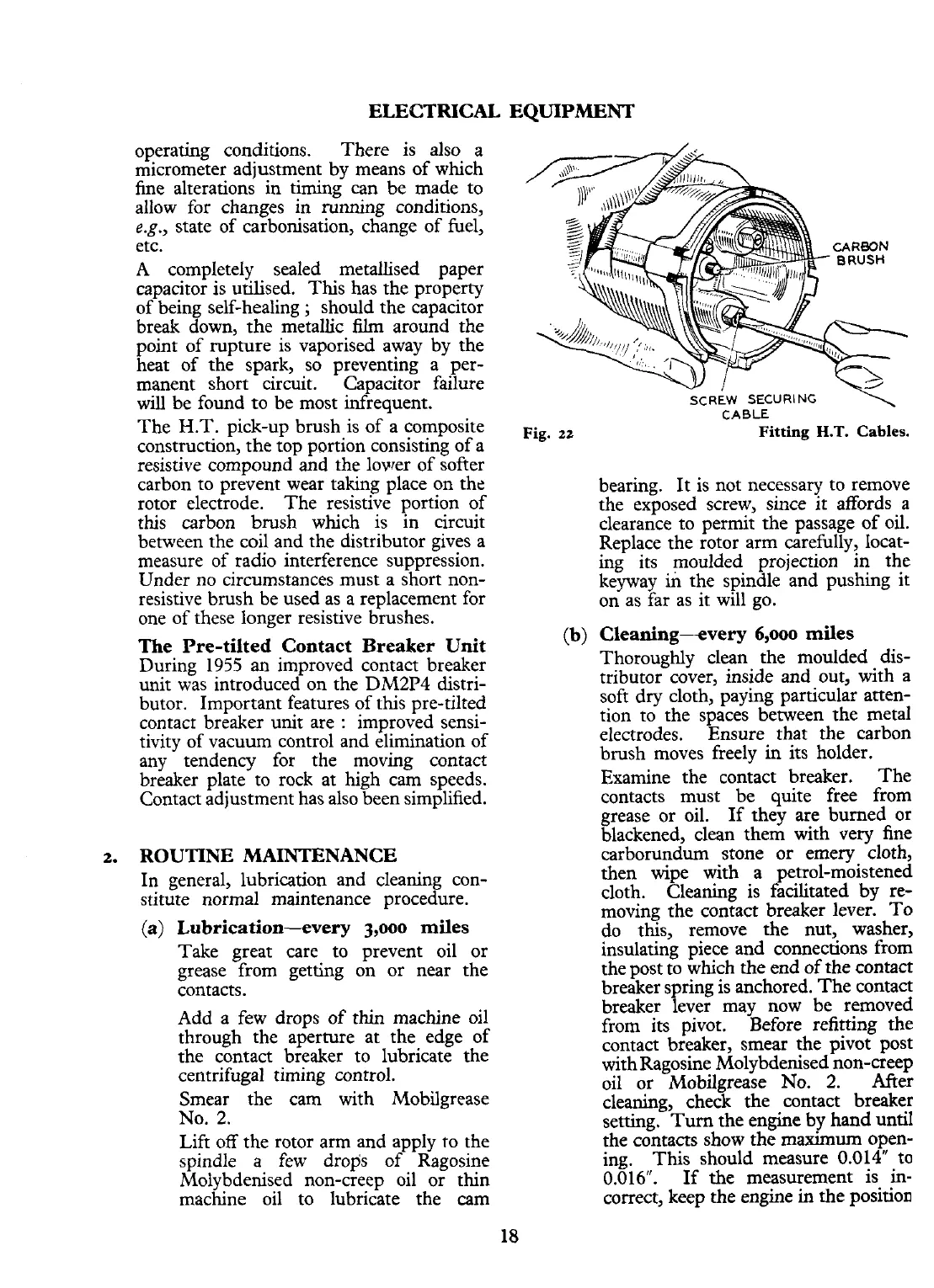

The

H.T.

pick-up brush is of a composite

construction, the top portion consisting of a

resistive compound and the lower of softer

carbon to prevent wear taking place on

the

rotor electrode. The resistive portion of

this carbon brush which is in circuit

between the coil and the distributor gives a

measure of radio interference suppression.

Under no circumstances must a short non-

resistive brush be used as a replacement for

one of these longer resistive brushes.

The Pre-tilted Contact Breaker Unit

During 1955 an imvroved contact breaker

unit w:s introducedon the DM2P4 distri-

butor. Important features of this pre-tilted

contact breaker unit are

:

improved sensi-

tivity of vacuum control and elimination of

any tendency for the moving contact

breaker plate to rock at high cam speeds.

Contact adjustment has also been simplified.

2.

ROUTINE MAINTENANCE

In general, lubrication and cleaning con-

stitute normal maintenance procedure.

(a) Lubrication--every

3,000

miles

Take great care to prevent oil or

grease from getting on or near the

contacts.

Add a few drops of thin machine oil

through the aperture at the edge of

the contact breaker to lubricate the

centrifugal timing control.

Smear the cam with Mobilgrease

No.

2.

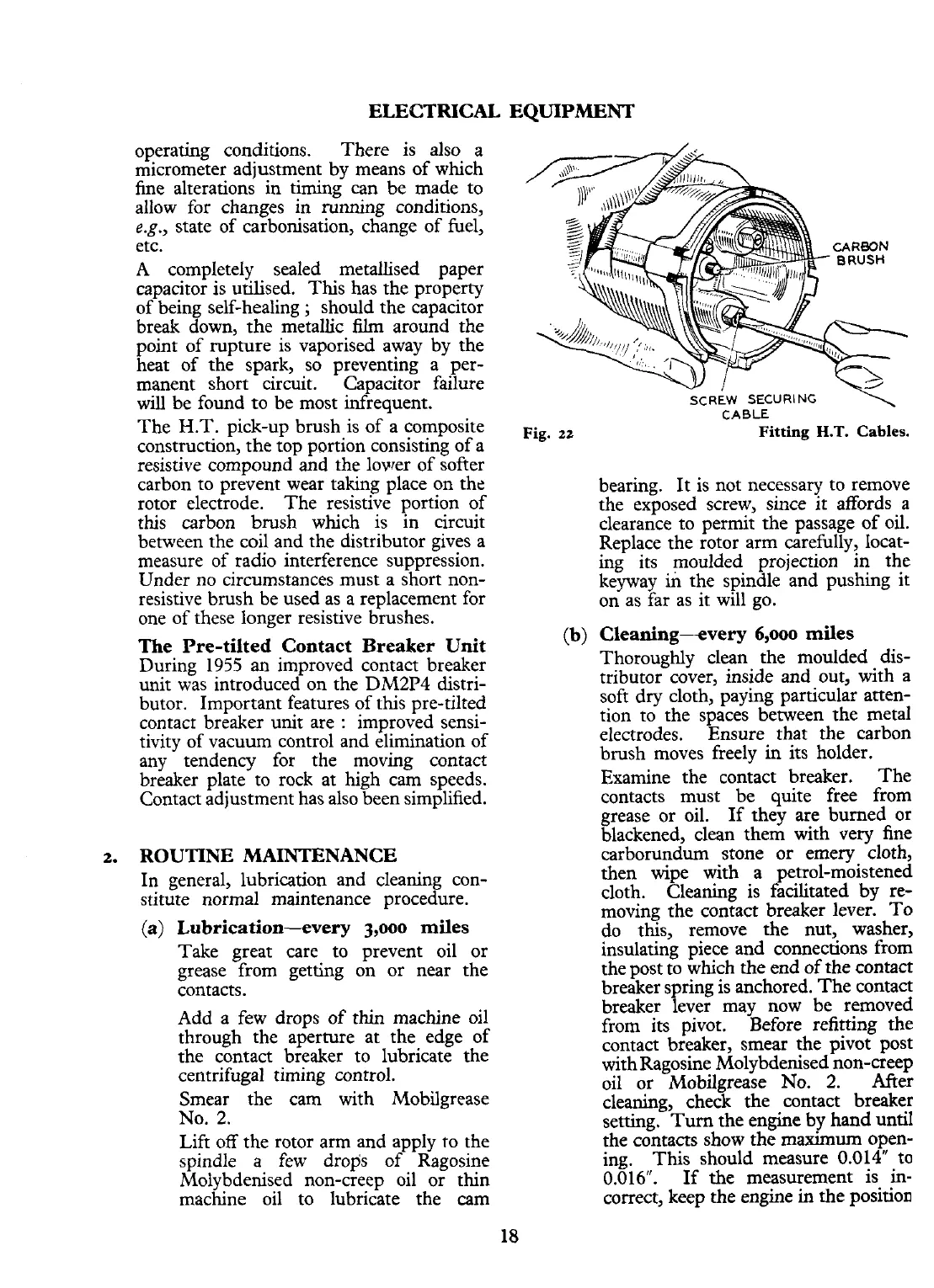

Lift off the rotor arm and apply to the

spindle

a

few drops of Ragosine

Molybdenised non-creep oil or thin

machine oil to lubricate the cam

SCREW

SECURING

\

CABLE

Fig.

zz

Fitting

H.T.

Cables.

bearing. It is not necessary to remove

the exposed screw, since it affords a

clearance to permit the passage of oil.

Replace the rotor arm carefully, Iocat-

ing its moulded projection in the

keyway

h

the spindle and pushing it

on as far as it will go.

(b) Cleaningevery

6,000

miles

Thoroughly clean the moulded dis-

tributor cover, inside and out, with a

soft dry cloth, paying particular atten-

tion to the spaces between the metal

electrodes. Ensure that the carbon

brush moves freely in its holder.

Examine the contact breaker. The

contacts must be quite free from

grease or oil. If they are burned or

blackened, clean them with very fine

carborundurn stone or emery cloth,

then wipe with

a

petrol-moistened

cloth. Cleaning is facilitated by re-

moving the contact breaker lever. To

do this, remove the nut, washer,

insulating piece and connections from

the post to which the end of the contact

breaker spring is anchored. The contact

breaker lever may now be removed

from its pivot. Before refitting the

contact breaker, smear the pivot post

with Ragosine Molybdenised non-creep

oil or Mobilgrease No.

2.

After

cleaning, check the contact breaker

setting. Turn the engine by hand until

the contacts show the

maximum open-

ing. This should measure

0.014

to

0.016".

If the measurement is in-

correct, keep the engine in the position

Loading...

Loading...