ELECTRICAL

EQUrPIMENT

(v) Fit the capacitor into position,

on earlier models the eyelet on

the other end of the contact

breaker earthing lead is held under

the capacitor fixing screw. Place

the fixed contact plate in position

and secure lightly with securing

saew(s), One plain and one

spring washer must be fitted under

each of these screws.

(vi) Place the insulating washers on the

contact breaker pivot post and on

the pillar on which the end of the

contact breaker spring locates.

Refit the contact breaker lever and

spfing.

(vii)

Shde the rubber terminal block

.

,

into its slot.

(viii) Thread the low tension connector

and capacitor eyelets on to the

insulating piece, and place these

on to the pillar which secures the

end of the contact breaker spring.

Refit the washer and securing nut.

(ix)

Set the contact gap to 0.014" to

0.016" and tighten the securing

screw(s) of the fixed contact plate.

(X)

Refit the rotor arm, locating the

moulded projection in the rotor

arm

with the keyway

in

the shafi

and pushing fully home. Refit the

moulded cover.

(h)

Replacement Contacts

If the contacts are so badly worn that

replacement is necessary, they must

be

renewed as a pair and not individ-

ually. The contact gap must be set to

0.014" to 0.016"

;

after the first

500

miles running with new contacts fitted,

the setting should

be

checked and the

gap reset to 0.014" to 0.016". This

procedure allows for the initial

"

bedding-in

"

of the heel.

ADLAMPS-MODEL

F700

IMK/VI

General Description

The lamps incorporate a combined reflector

and front lens assembly known as the Lucas

Light Unit. They

are

fitted

with

a

"

pre-

focus

"

bulb which ensures that the filament

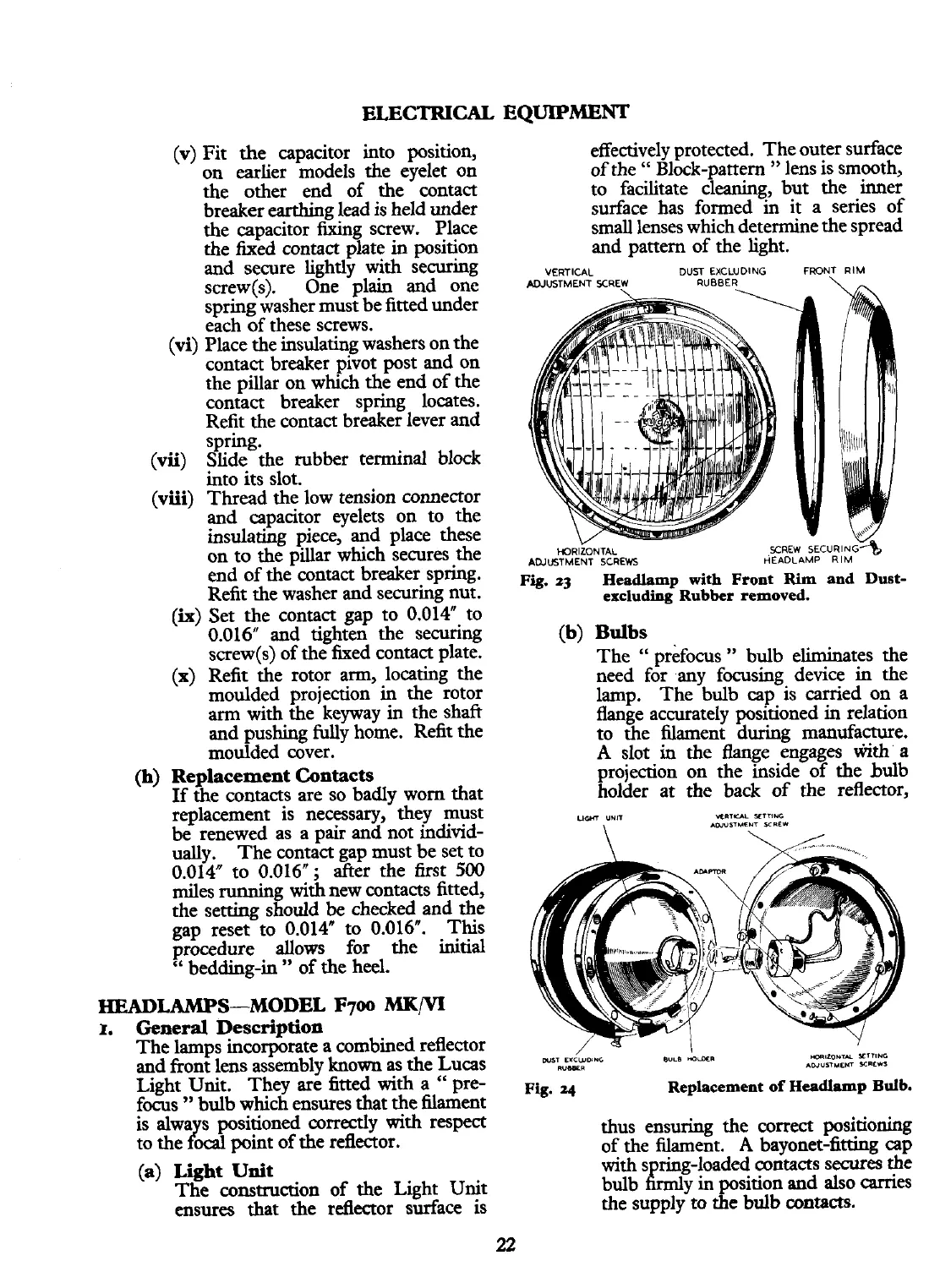

effectively protected. The outer surface

of the

"

Block-pattern

"

lens is smooth,

to facilitate cleaning, but the inner

surface has formed in it a series of

small lenses which determine the spread

and pattern of the light.

VERTICAL

DUST EXCLUDING FRONT RIM

ADJUSTMENT XREW

RUBBER

\

V

v

MRIZONTAL

SCREW

SECURING*

ADJUSTMENT SCREWS

HEADLAMP

RIM

Fig,

q

Headlamp

with

Front

Rim

and Dust-

excluding Rubber removed.

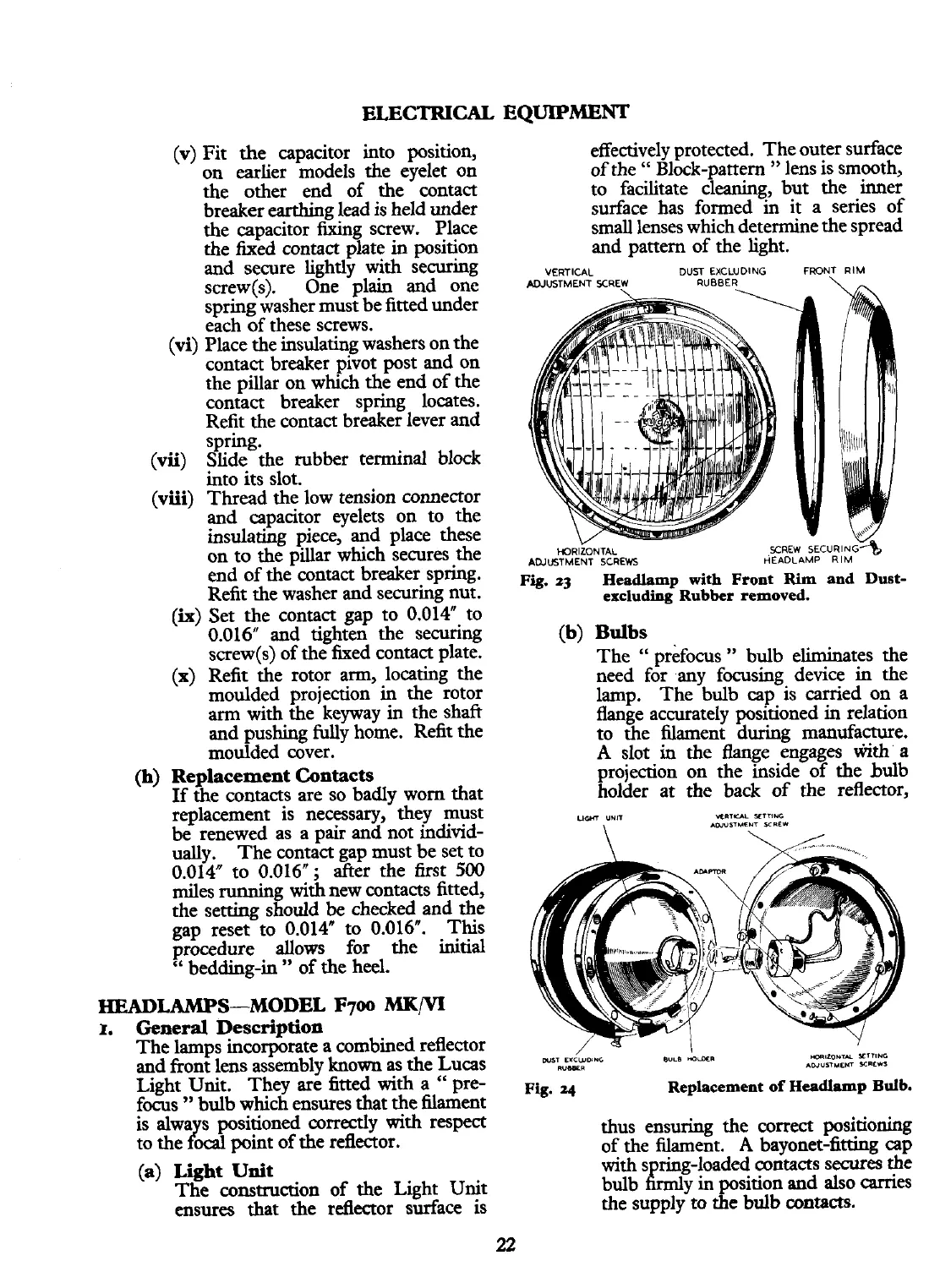

(b) Bulbs

The

"

prefocus

"

bulb eliminates the

need for any focusing device

in

the

lamp. The bulb cap is carried on a

flange accurately positioned

in

relation

to the filament during manufacture.

A

slot

in

the flange engages

FMI

a

projection on the inside of the bulb

holder at the back of the reflector,

ucn

uun

K~T-

SETTING

WST

EXCWDINC

eum

aiaa

-I*.,*TY

SETTING

*"W*

AWYnULm

YlCll

Fig.

4

Replacement of Headlamp

Bulb.

is alwa

s

positioned correctly with respect

r

thus ensuring the correct positioning

to the

ocal

point of the reflector.

of the filament.

A

bayonet-fitting cap

(a) Light Unit

with s ring-loaded

wntaas

secures the

The construction of the Light Unit

bulb

&mly

in position and also carries

ensures that the reflector surface is

the supply to the bulb contacts.

Loading...

Loading...