ELECTRICAL

EQWMENT

2.

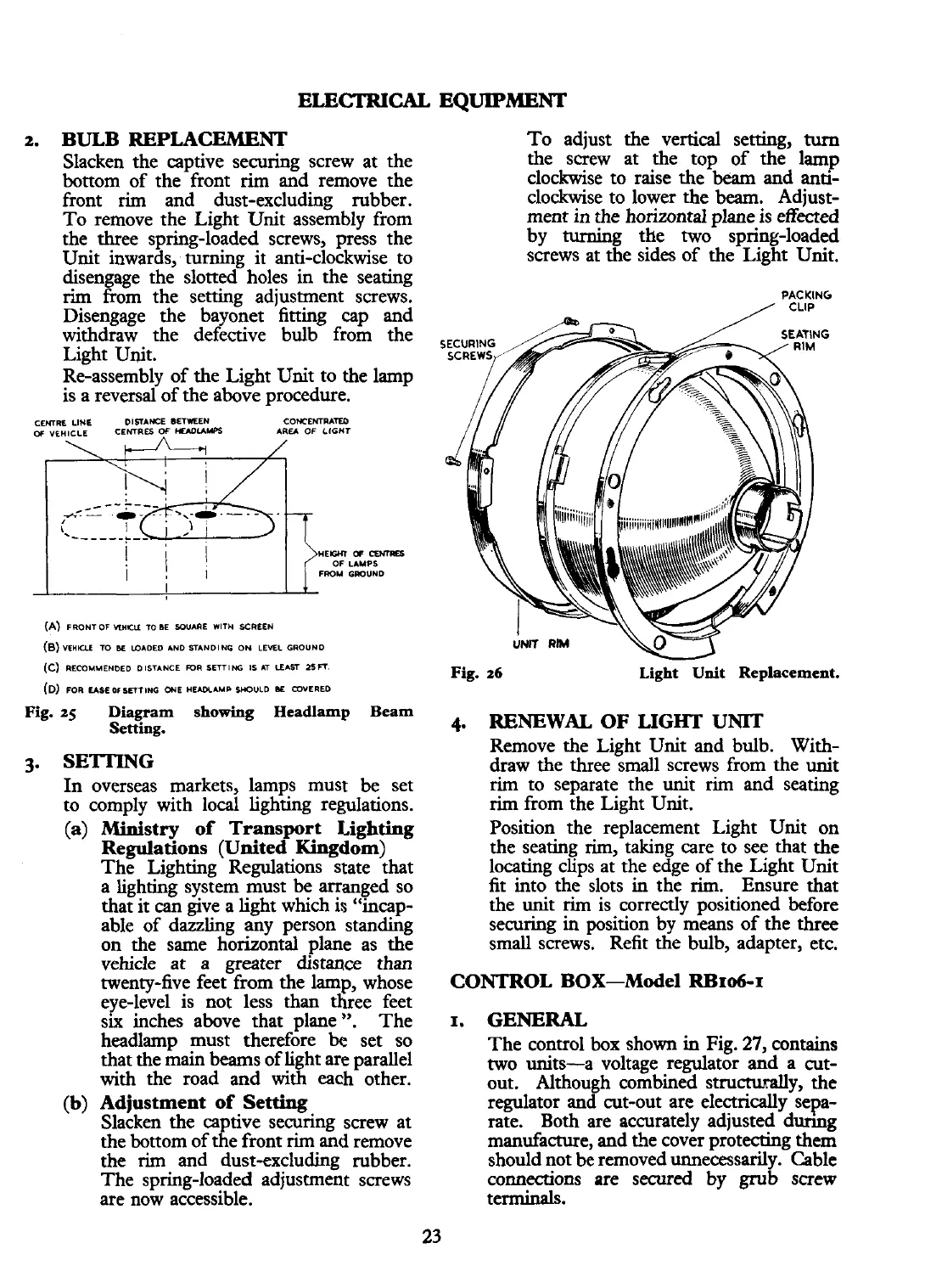

BULB REPLACEMENT To adjust the vertical setting,

turn

Slacken the captive securing screw at the

the screw at the top of the lamp

bottom of the front

rim

and remove the

clockwise to raise the

beam

and anti-

front

rim

and dust-excluding rubber. clockwise to lower the

beam.

Adjust-

To remove the Light Unit assembly from ment in the horizontal plane is effected

the three spring-loaded screws, press the by turning the two

springloaded

Unit inwards, turning it anti-clockwise to screws at the sides of the Light Unit.

disengage the slotted holes in the seating

rim

from the setting adjustment screws.

PACKING

Disengage the bayonet fitting cap and

withdraw the defective bulb from the

G

Light Unit.

Re-assembly of the Light Unit to the lamp

is a reversal of the above procedure.

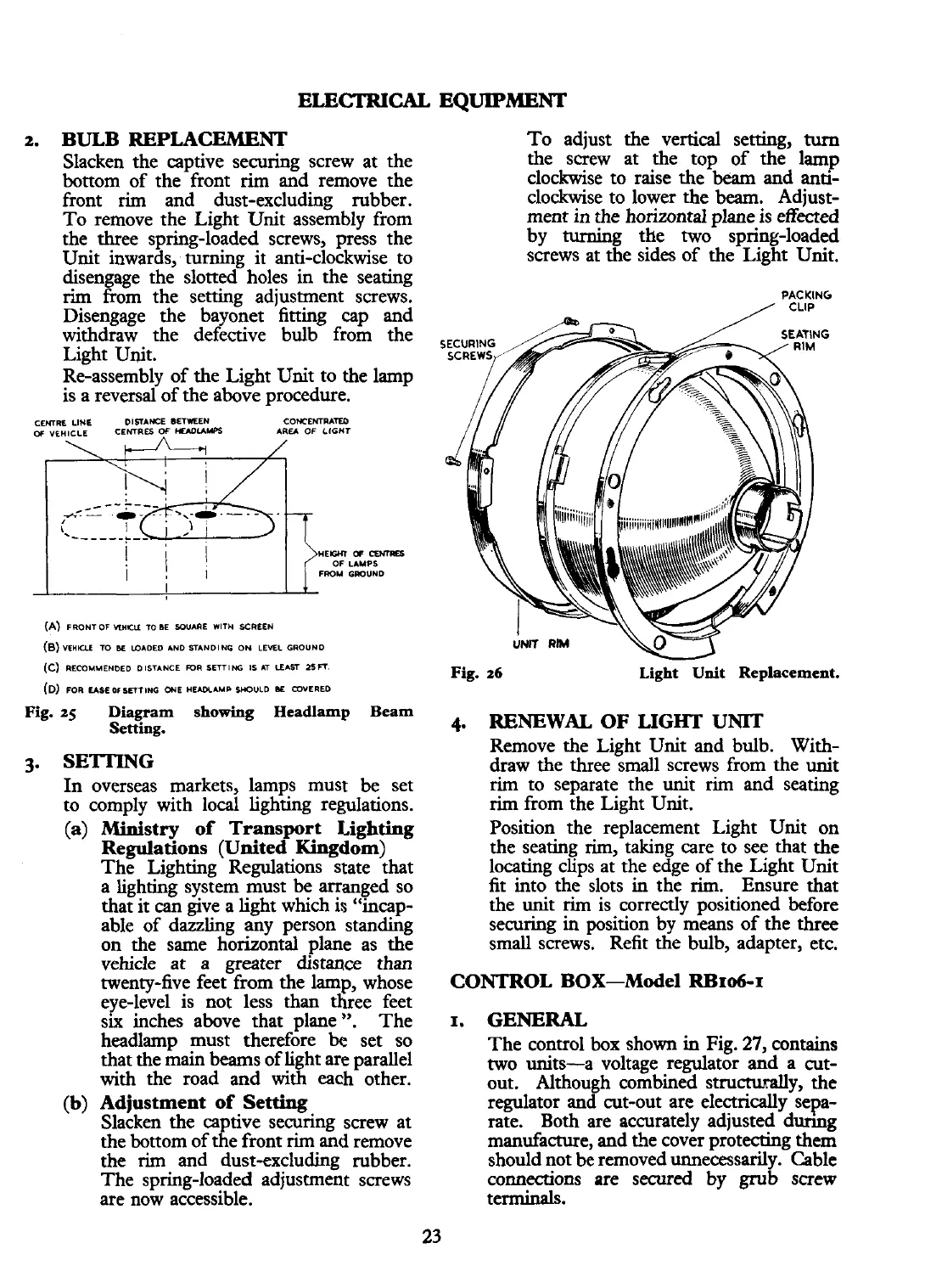

CEMRL

LINE DISTAWCE BETWEEN CONCENTMM

AREA

OF

LIGHT

WElCYT

ff

CEhlRB

OF LAMPS

FROM GMUND

(A)

FRONTOF

WlUL

TO

M

SOUARE

WlTU

KREEN

(8)vr~Klt

X)

M

WADED AND STANDING ON LEML GROUND

(c)

RECOUMEH~ED

DISTANCE

-R

SETTING

IS

AT

LEm

zsn.

Fig.

26

Light Unit Replacement.

(D)

FOR EASEOISEfTING ONE

H-AMP

SHOULD

M

COVERED

Fig.

25

Diagram showing Headlamp Beam

Setting.

4.

RENEWAL

OF

LIGHT

UNIT

Remove the Light Unit and bulb.

With-

3.

SETTING

draw the three small screws from the unit

In overseas markets, lamps must be set

rim

to separate the unit

rim

and seating

to comply with local lighting regulations.

rim

from the Light Unit.

(a) Ministry of Transport Lighting Position the replacement Light Unit on

Regulations (United Kingdom)

the seating rim, taking care to see that the

The Lighting Regulations state that

locating clips at the edge of the Light Unit

a lighting system must be arranged so

fit into the slots in the

rim.

Ensure that

that it can give a light which is "incap-

the unit

rim

is correctly positioned before

able of dazzling any person standing

securing

in

position by means of the three

on the same horizontal plane as the

small screws. Refit the bulb, adapter, etc.

vehicle at

a

greater distance than

twenty-five feet from the lamp, whose

CONTROL BOX-Model

Rl3106-I

eye-level is not less

than

three feet

six inches above that plane

".

The

I.

GENERAL

headlamp must therefore

be

set so

The control

box

shown

in

Fig.

27,

contains

that the main beams of light are parallel

two units-a voltage regulator and a

cut-

with the road and with each other.

out. Although combined structurally, the

(b)

Adjustment of Setting

regulator and cut-out

are

electrically sepa-

Slacken the captive securing screw at

rate. Both are accurately adjusted dunng

the bottom of the front

rim

and remove

manufacture, and the cover protecting them

the rim and dust-excluding rubber.

should not be removed unnecessarily. Cable

The spring-loaded adjustment screws

co~eaions are secured by grub screw

are now accessible. terminals.

23

Loading...

Loading...