ELECTRICAL EQUIPMENT

removed, these settings should not

be tampered with. If, however,

the armature has been removed,

the regulator

will

have to be reset.

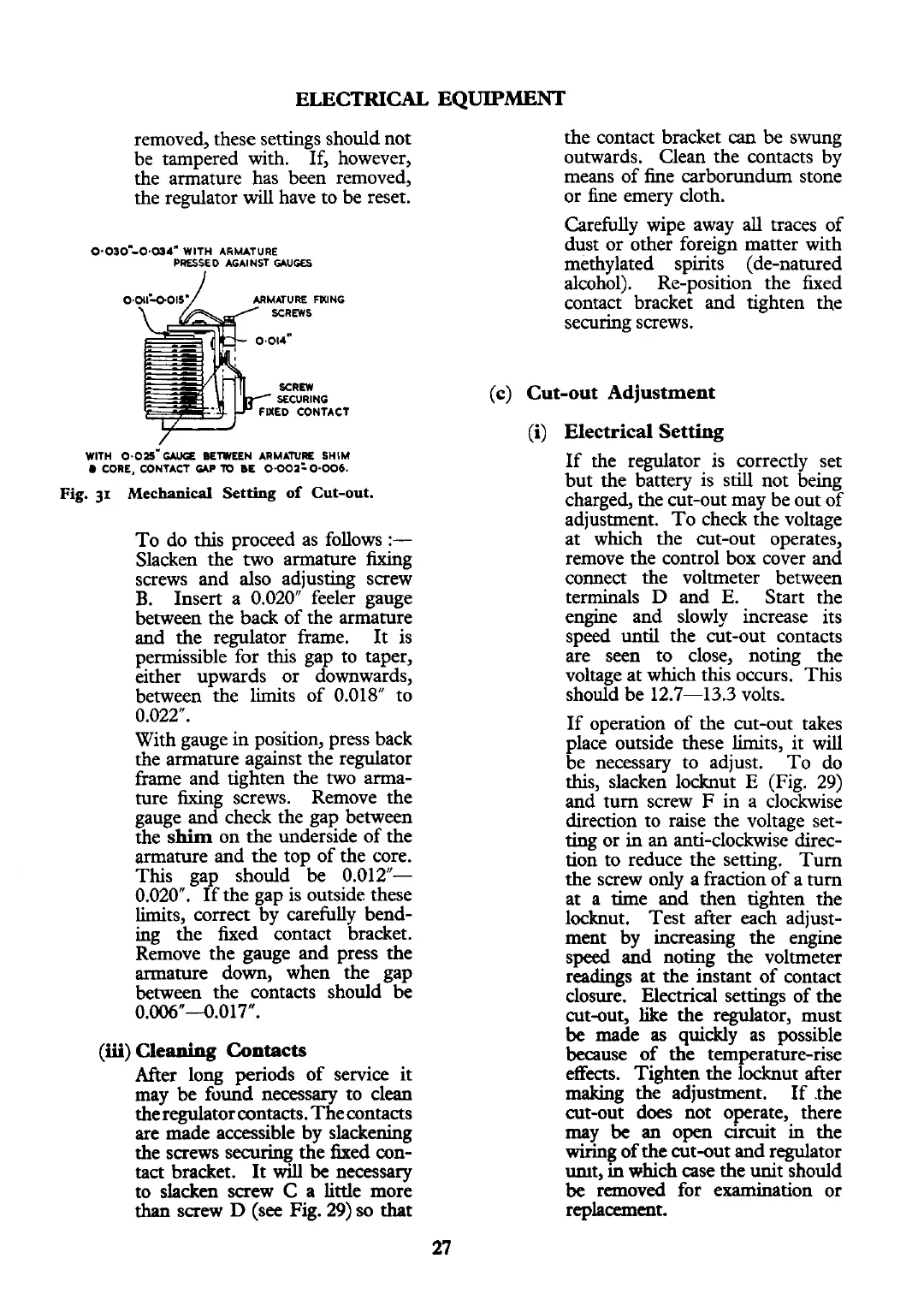

0.030-0.(~4^ WlTH ARMATURE

PRESSED AGAINST

C*UGES

ARMATURE mlNG

UED CONTACT

WlTH 0.025-- BETWEEN ARMATURE SHIM

CORE, CONTACT

UP

X)

BE 0.002=0.006.

Fig.

31

Mechanical

Setting

of Cut-out.

To do this proceed as follows

:-

Slacken the two armature fixing

screws and also adjusting screw

B.

Insert a 0.020" feeler gauge

between the back of the armature

and the regulator frame.

It is

permissible for this gap to taper,

either upwards or downwards,

between the limits of 0.018" to

0.022.

With gauge in position, press back

the armature against the regulator

frame and tighten the two arma-

ture fixing screws. Remove the

gauge and check the gap between

the

shim

on the underside of the

armature and the top of the core.

This gap should be 0.012"-

0.020". If the gap is outside these

limits, correct by carefully bend-

ing the fixed contact bracket.

Remove the gauge and press the

armature down, when the gap

between the contacts should be

0.006"--0.017".

(M)

Cleaning Contacts

After long periods of service it

may

be

found necessary to clean

the regulator contacts. The contacts

are made accessible by slackening

the screws securing the fixed mn-

tact bracket. It

will

be

necessary

to slacken screw

C

a little more

than

screw

D

(see Fig.

29)

so

that

the contact bracket

can

be swung

outwards. Clean the contacts by

means of

he carborundum stone

or fine emery cloth.

Carefully wipe away

all

traces of

dust or other foreign matter with

methylated spirits (de-natured

alcohol). Re-position the fixed

contact bracket and tighten the

securing screws.

(c) Cut-out Adjustment

(i)

Electrical Setting

If the regulator is correctly set

but the battery is still not being

charged, the cut-out may be out of

adjustment. To check the voltage

at which the cut-out operates,

remove the control box cover and

connect the voltmeter between

terminals

D

and

E.

Start the

engine and slowly increase its

speed until the cut-out contacts

are seen to close, noting the

voltage at which this occurs. This

should be

12.7-13.3

volts.

If operation of the cut-out takes

place outside these limits, it

will

be necessary to adjust. To do

this, slacken locknut

E

(Fig. 29)

and turn screw

F

in a clockwise

direction to raise the voltage set-

ting or in an anti-clockwise direc-

tion to reduce the setting. Turn

the screw only a fraction of a turn

at a time and then tighten the

locknut. Test after each adjust-

ment by increasing the engine

speed and noting the voltmeter

readings at the instant of contact

closure.

Electrical

settings of the

cut-out, like the regulator, must

be

made

as

quickly as possible

because of the temperature-rise

effects. Tighten the locknut after

making the adjustment. If .the

cut-out

does

not operate, there

may

be

an

open circuit in the

wiring

of the cut-out and regulator

mt,

in

which case the unit should

be

removed for examination or

replacement.

Loading...

Loading...