ELECTRICAL

EQUIPMENT

(ii) Mechanical Setting

If for any reason the cut-out

armature has to be removed from

the frame, care must be taken to

obtain the correct air-gap settings

on re-assembly (see Fig. 31). These

can

be obtained as follows

:-

Slacken the two armature furing

screws, adjusting screw

F

and the

screw securing the fixed contact.

Insert a 0.014 gauge between the

back of the armature and the cut-

out frame. (The air gap between

the core face and the armature

shim should now measure 0.011"

-4.015". If it does not,

fit

a new

armature assembly.) Press the

armature back against the gauge

and tighten the armature fixing

screws. With the gauge still in

position, set the gap between the

armature and the stop plate arm

to 0.030"---0.034" by carefully

bending the stop plate arm. Re-

move the gauge and tighten the

screw securing the fixed contact.

Insert a 0.025" gauge between the

core face and the armature. Press

the armature down on to the

~ ~

gauge. The gap between the con-

tacts should now measure 0.002"

to 0.006" and the drop-off voltage

should be between the limits

given

in

Para.

2

(b). If necessary,

adjust the gap by carefully

bending the fixed contact bracket.

(iii) Cleaning Contacts

If the cut-out contacts appear

rough or burnt, place a strip of

fine glass paper between the con-

tacts-then, with the contacts

closed by hand, draw the paper

through. This should be done

two or three times with the rough

side towards each contact. Wipe

away all dust or other foreign

matter, using a clean

fluffless cloth

moistened with methylated spirits

(de-natured alcohol).

Do not use emery cloth or a car-

borundum stone for cleaning cut-

out contacts.

WINDSCREEN WIPER CRTI~

I.

GENERAL

Normally the windscreen wiper will not

require any servicing apart from the oc-

casional renewal of the rubber blades.

In the event of irregular working, first check

for loose connections, chafed insulation,

discharged battery, etc., before removing

the gearbox or commutator covers.

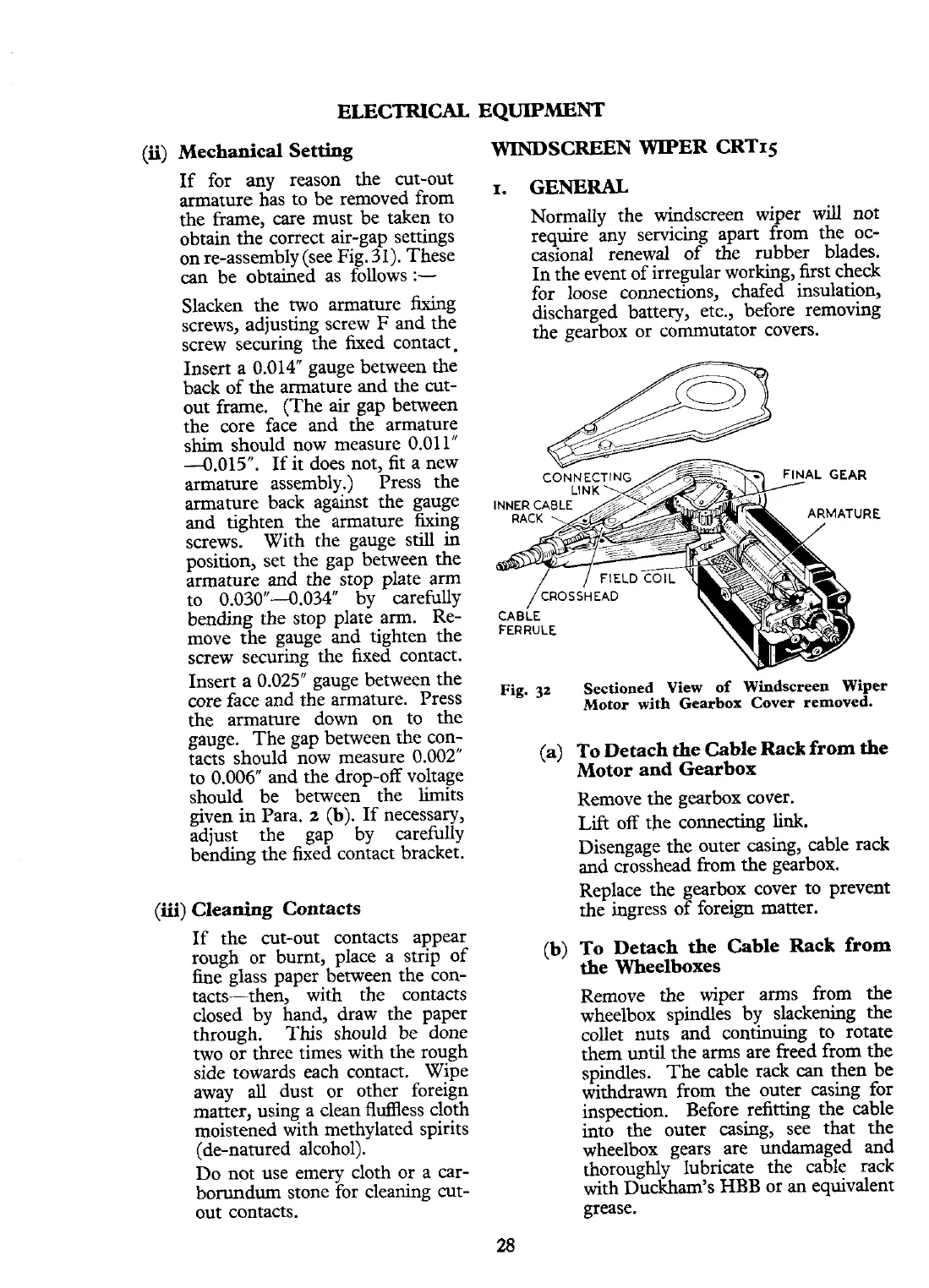

Fig.

32

Sectioned View of Windscreen Wiper

Motor with Gearbox Cover removed.

(a) To Detach

the

Cable Rack from

the

Motor and Gearbox

Remove the gearbox cover.

Lift

off the connecting

link.

Disengage the outer casing, cable rack

and crosshead from the gearbox.

Replace the gearbox cover to prevent

the ingress of foreign matter.

(b) To Detach the Cable Rack from

the Wheelboxes

Remove the wiper arms from the

wheelbox spindles by slackening the

collet nuts and continuing to rotate

them

until

the arms are freed from the

spindles. The cable rack

can

then be

withdrawn from the outer casing for

inspection. Before refitting the cable

into the outer casing, see that the

wheelbox gears are undamaged and

thoroughly lubricate the cable

rack

with Duckham's HBB or an equivalent

grease.

Loading...

Loading...