ELECTRICAL

EQUIPMENT

Withdraw the cables from control

box terminals

A

and

A1

and

connect these cables together.

Connect the negative lead of the

voltmeter to control box terminal

D,

and connect .the other lead to

terminal

E.

Slowly increase the speed of the

engine until the voltmeter needle

"

flicks

"

and then steadies. This

should occur at a voltmeter read-

ing between the appropriate limits

given in Para.

2

(a)

according to

the ambient temperature.

If the voltage at which the reading

becomes steady occurs outside

these limits, the regulator must

be adjusted.

Shut off the engine and remove

the control box cover.

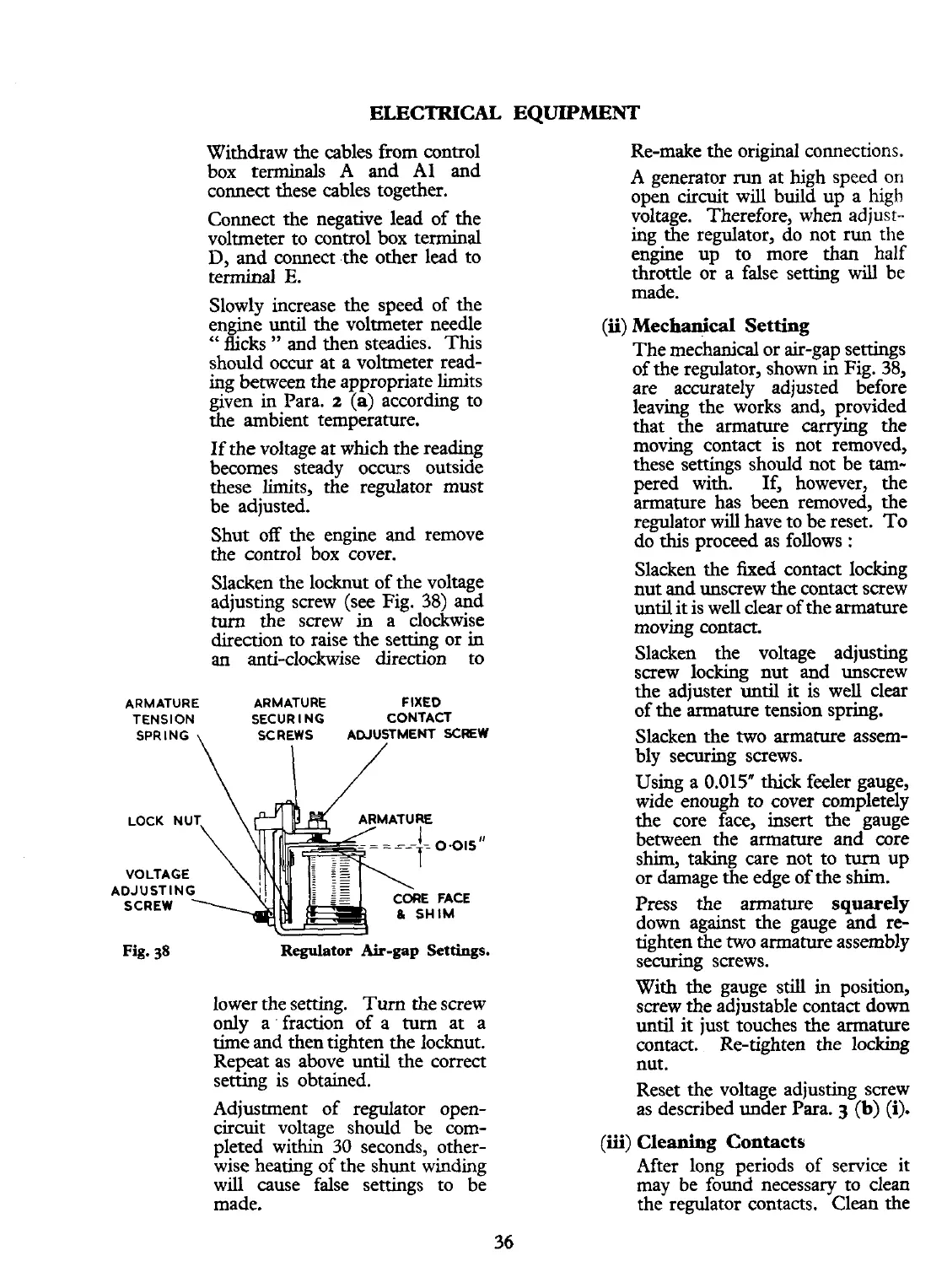

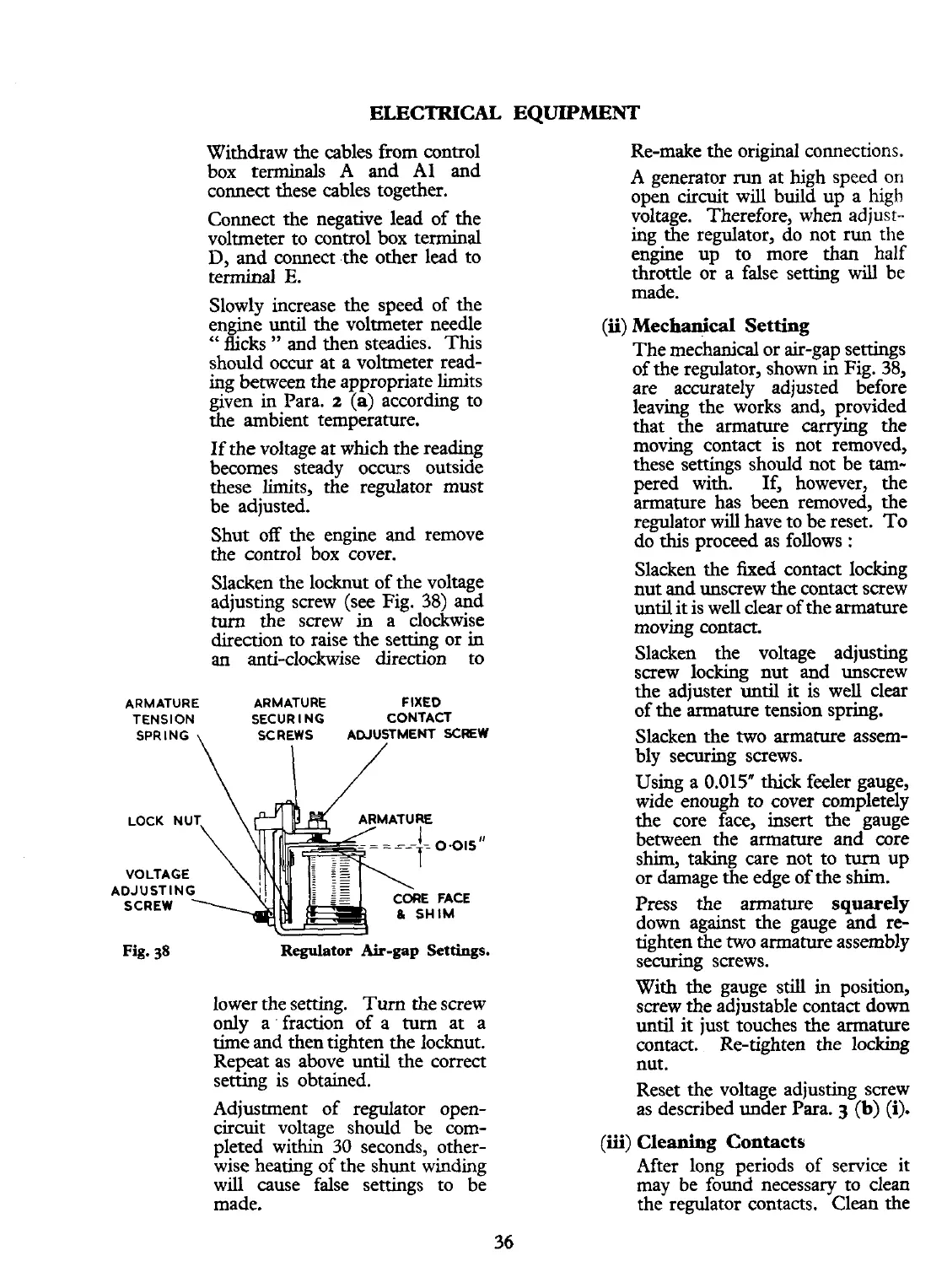

Slacken the

locknut of the voltage

adjusting screw (see Fig.

38)

and

turn

the screw

in

a clockwise

direction to raise the setting or in

an

anti-clockwise direction to

ARMATURE ARMATURE FIXED

TENSION

SECURING CONTACT

SPRING

\

SCREWS ADJUSTMENT

SCREW

VOLTAGE

ADJUSTING

Fig.

38

Regulator Air-gap Settings.

lower the setting.

Turn the screw

only a. fraction of a

turn

at a

time

and then tighten the locknut.

Repeat as above until the correct

setting is obtained.

Adjustment of regulator open-

circuit voltage should be com-

pleted within

30

seconds, other-

wise heating of the shunt winding

will cause false settings to be

made.

Re-make the original connections.

A

generator

run

at high speed on

open circuit will build up a

high

voltage. Therefore, when adjust-

ing the regulator, do not

run

the

engine up to more than half

throttle or a false setting will be

made.

(ii)

Mechanical Setting

The mechanical or air-gap settings

of the regulator, shown in Fig.

38,

are accurately adjusted before

leaving the works and, p!ovided

that the armature carrymg the

moving contact is not removed,

these settings should not be

tarn-

pered with. If, however, the

armature has been removed, the

regulator will have to be reset. To

do this proceed as follows

:

Slacken the fixed contact locking

nut and unscrew the contact screw

until it is well clear of the armature

moving contact.

Slacken the voltage adjusting

screw locking nut and unscrew

the adjuster until

it

is well clear

of the armature tension spring.

Slacken the two armature assem-

bly securing screws.

Using a

0.015"

thick feeler gauge,

wide enough to cover completely

the core face, insert the gauge

between the armature and core

shim, taking care not to

turn

up

or damage the edge of the shim.

Press the armature

squarely

down against the gauge and re-

tighten the two armature assembly

securing screws.

With the gauge still in position,

screw the adjustable contact down

until it just touches the armature

contact. Re-tighten the locking

nut.

Reset the voltage adjusting screw

as described under

Para.

3

(b)

(i).

(iii)

Cleaning Contacts

After long periods of service it

may be found necessary to clean

the regulator contacts. Clean the

Loading...

Loading...