FUEL

SYSTEM

turns passes into the lower body of the

petrol pump below the diaphragm assembly

and by action

ofthe latter is pumped out

by way of the breather hole.

To obviate tlus condition an oil seal is

fitted round the diaphragm assembly push

rod and is prevented from rising

with

the

action of the push rod by a metal retainer

staked to the lower pump body.

Petrol pumps fitted with this oil seal were

fitted to engines after

No.

TS.2074E.

E

W-Io

PR,H8NC

LIYII1

During dismantling this oil seal should not

be removed unless it is known to be

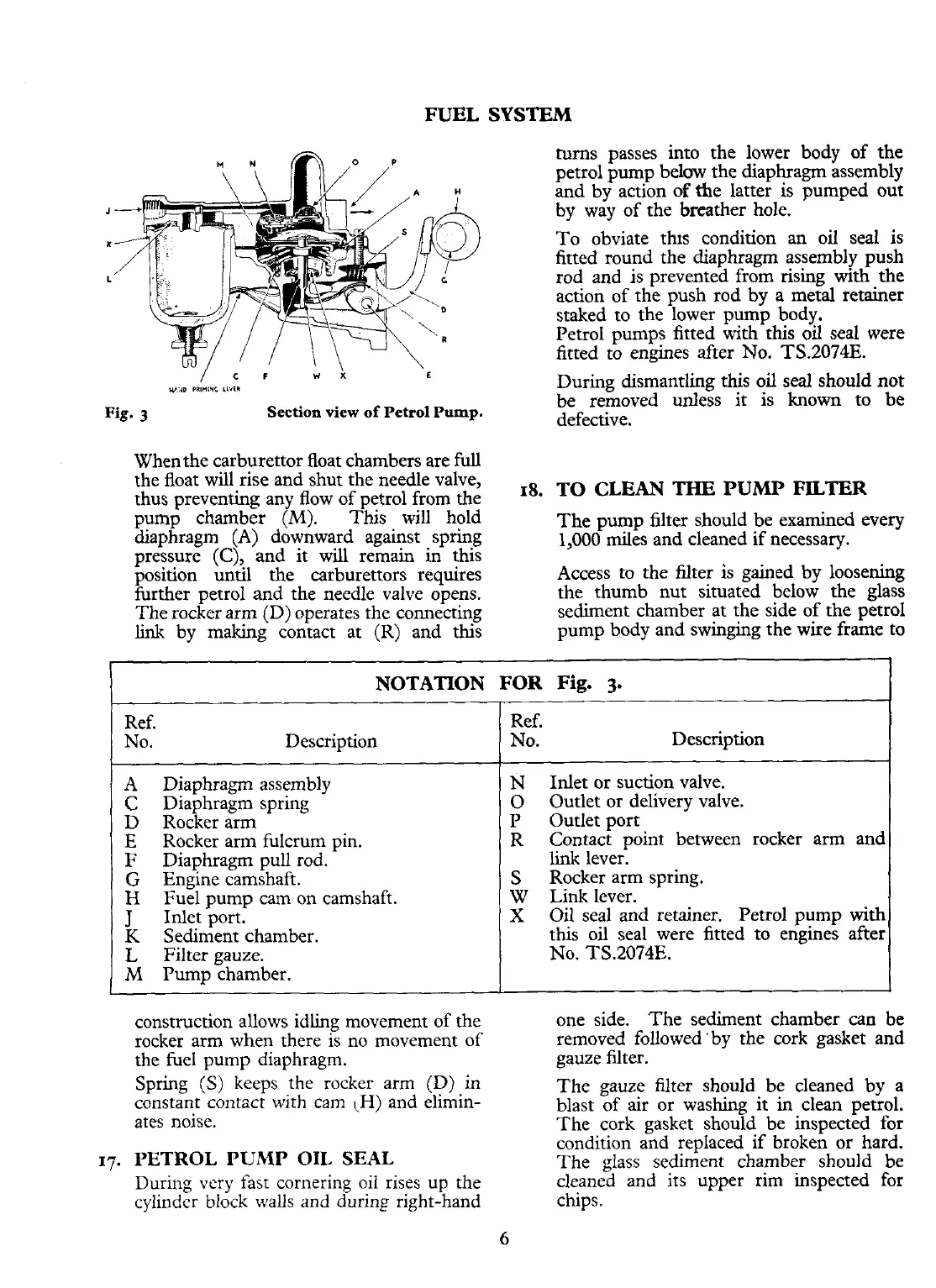

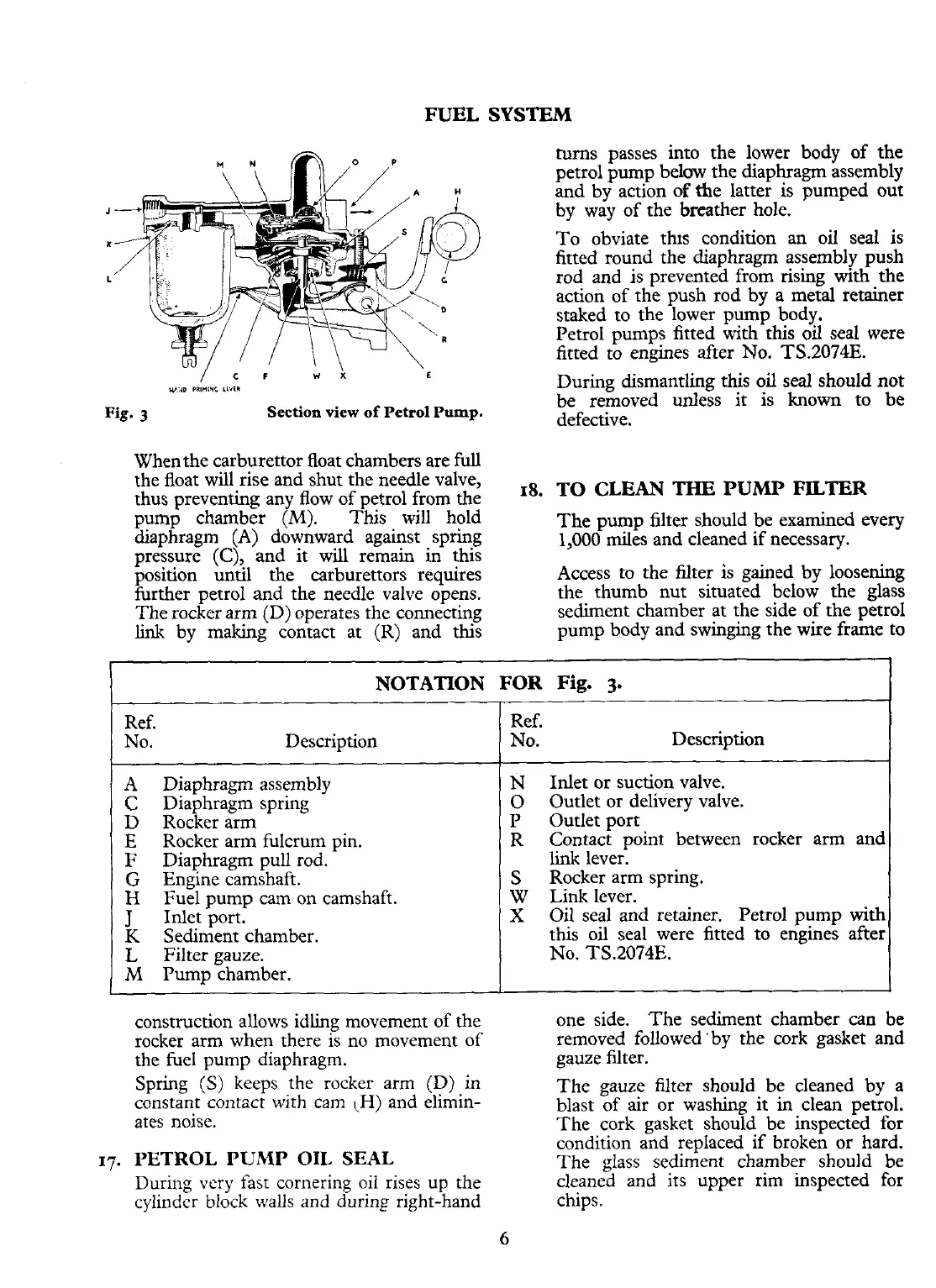

Fig.

3

Section

view

of Petrol Pump.

defective.

Whenthe carburettor float chambers are

full

the float will rise and shut the needle valve,

TO

CLEAN

THE

mTER

thus preventing any flow of petrol from the

pump chamber

(M).

This will hold The pump filter should be examined every

diaphragm

(A)

downward against spring

1,000 miles and cleaned if necessary.

pressure

(C),

and it will remain in this

position until the carburettors requires Access to the filter is gained by loosening

further petrol and the needle valve opens. the thumb nut situated below the glass

The rocker arm

(D)

operates the connecting sediment chamber at the side of the petrol

link

by making contact at (R) and this pump body and swinging the wire frame to

l

NOTATION

FOR Fig.

3.

Ref.

No. Description

A

Diaphragm assembly

C

Diaphragm spring

D

Rocker arm

E

Rocker arm fulcrum pin.

F

Diaphragm pull rod.

G

Engine camshaft.

H

Fuel pump cam on camshaft.

J

Inlet port.

K

Sediment chamber.

L

Filter gauze.

M

Pump chamber.

construction allows idling movement of the

rocker arm when there is no movement of

the

fuel pump diaphragm.

Spring

(S)

keeps the rocker arm (D)

in

constant contact with cam

(H)

and elimin-

ates noise.

17.

PETROL PUMP OIL

SEAL

During very fast cornering oil rises up the

cylinder block walls and during right-hand

Ref.

No.

Description

N

Inlet or suction valve.

O Outlet or delivery valve.

P

Outlet port

R

Contact point between rocker arm and

link

lever.

S Rocker arm spring.

W

Link lever.

X

Oil seal and retainer. Petrol pump

with

this oil seal were fitted to engines after

No. TS.2074E.

one side. The sediment chamber

can

be

removed followedby the cork gasket and

gauze filter.

The gauze filter should be cleaned by a

blast of air or washing it in clean petrol.

The cork gasket should be inspected for

condition and replaced

if

broken or hard.

The glass sediment chamber should be

cleaned and its upper rim inspected for

chips.

Loading...

Loading...