FUEL SYSTEM

F&.

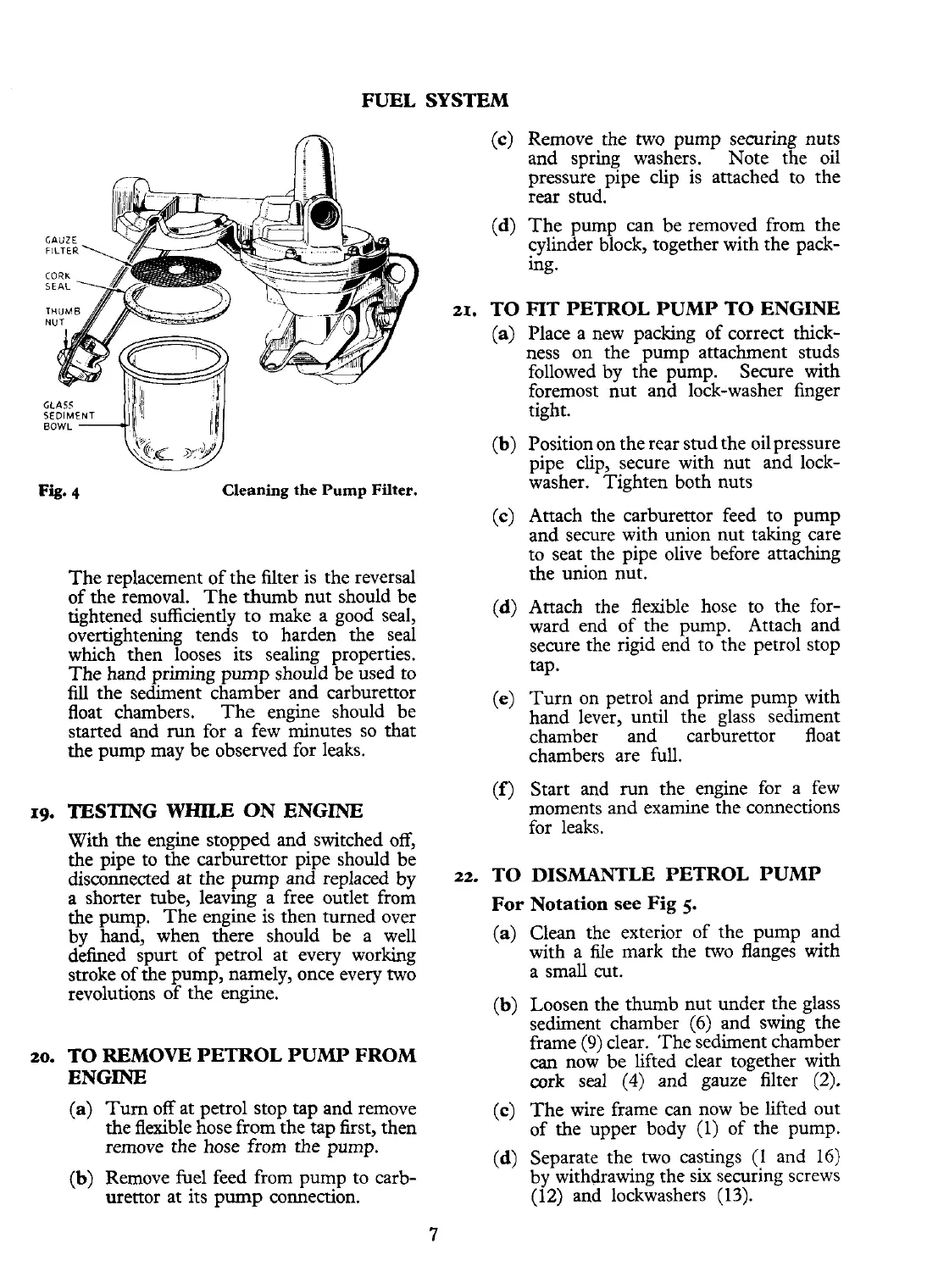

4

Cleaning

the

Pump

Filter.

The replacement of the Nter is the reversal

of the removal. The thumb nut should be

tightened sufficiently to make a good seal,

overtightening tends to harden the seal

which then looses its sealing properties.

The hand priming pump should be used to

fdl

the sediment chamber and carburettor

float chambers. The engine should be

started and run for a few minutes so that

the pump may be observed for leaks.

TESTING WHILE

ON

ENGINE

With the engine stopped and switched off,

the pipe to the carburettor pipe should be

disconnected at the pump and replaced by

22.

a

shorter tube, leaving a free outlet from

the pump. The engine is then turned over

by hand, when there should be a well

defined spurt of petrol at every working

stroke of the pump, namely, once every two

revolutions of the engine.

TO REMOVE PETROL PUMP FROM

ENGINE

(c)

Remove the two pump securing nuts

and spring washers. Note the oil

pressure pipe clip is attached to the

rear stud.

(d)

The pump can be removed from the

cylinder block, together with the pack-

ing.

21.

TO FIT PETROL PUMP TO ENGINE

(a)

Place a new packing of correct thick-

ness on the pump attachment studs

followed by the pump. Secure with

foremost nut and lock-washer finger

tight.

(a)

Turn off at petrol stop tap and remove

the flexible hose from the tap first, then

remove the hose from the pump.

(b)

Remove fuel feed from pump to carb-

urettor at its pump connection.

(b)

Position on the rear stud the oil pressure

pipe clip, secure with nut and lock-

washer. Tighten both nuts

(c)

Attach the carburettor feed to pump

and secure with union nut taking care

to seat the pipe olive before attaching

the union nut.

(d)

Attach the flexible hose to the for-

ward end of the pump. Attach and

secure the rigid end to the petrol stop

tap.

(e)

Turn on petrol and prime pump with

hand lever, until the glass sediment

chamber and carburettor float

chambers are full.

(f)

Start and run the engine for a few

moments and examine the connections

for leaks.

TO DISMANTLE PETROL PUMP

For Notation

see

Fig

5.

(a)

Clean the exterior of the pump and

with a file mark the two flanges with

a small cut.

(b)

Loosen the thumb nut under the glass

sediment chamber

(6)

and swing the

frame

(9)

clear. The sediment chamber

can

now be lifted clear together with

cork seal

(4)

and gauze filter

(2).

(c)

The wire frame can now be lifted out

of the upper body

(1)

of the pump.

(d)

Separate the two castings

(1

and

16)

by

withdrawing the six securing screws

(12)

and lockwashers

(13).

Loading...

Loading...