ENGINE

I.

CYLINDER BLOCK

Vandervell replaceable shell bearings have

been,introduced for the 2nd, 3rd and rear

camshaft journals. These are manufactured

to very fine limits, and whilst certain fitting

precautions must be observed, line boring

of the assembled bearings is unnecessary.

Removal of the rear bearing will necessitate

the removal of the sealing disc behind it,

which, in turn, will require the removal of

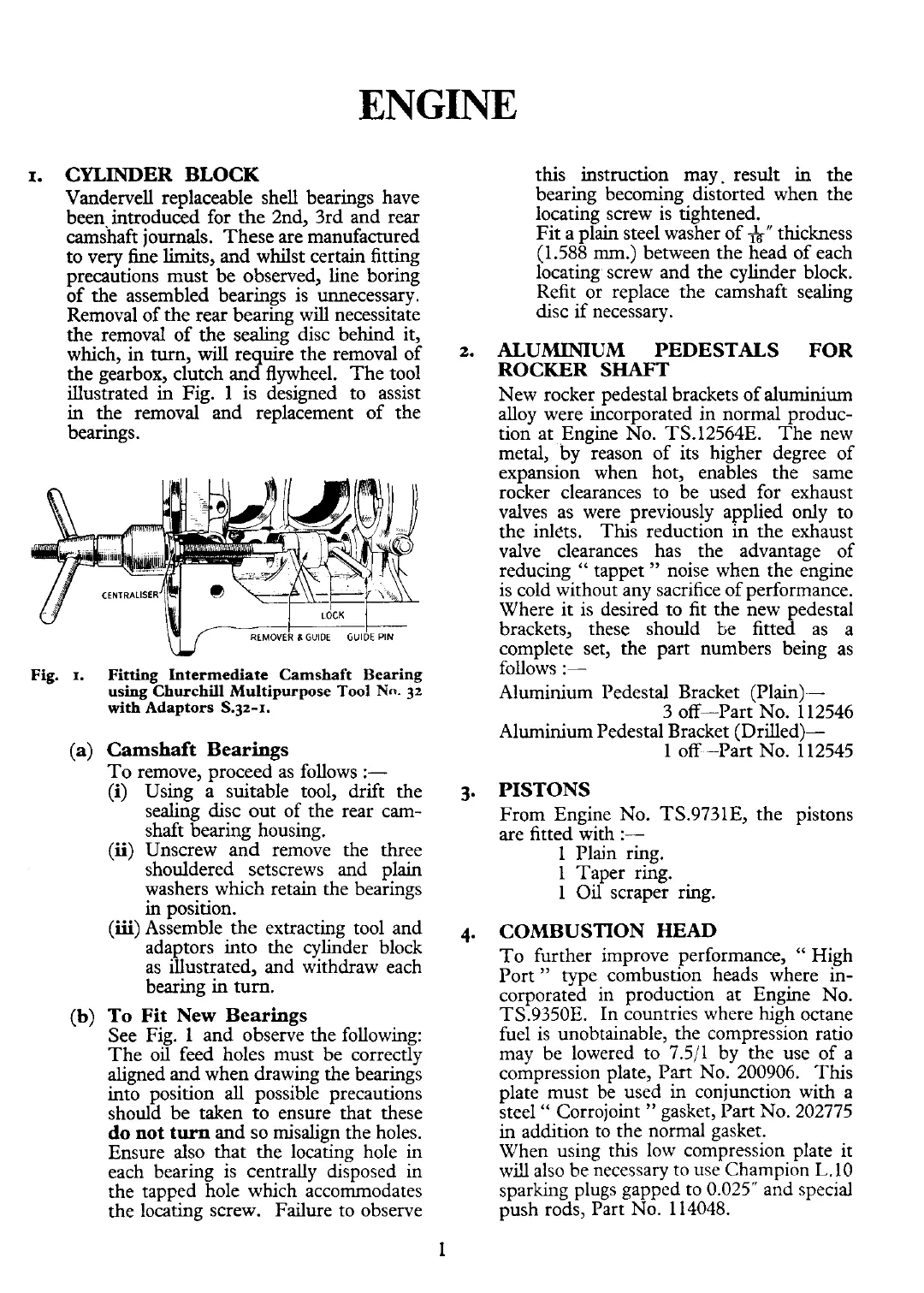

the gearbox, clutch and flywheel. The tool

illustrated in Fig. 1 is designed to assist

in the removal and replacement of the

bearings.

REMOVER &GUIDE GUIDE PIN

kLC

Fig.

I.

Fitting Intermediate Camshaft Bearing

using Churchill Multipurpose Tool

Nn.

32

with

Adaptors

S.32-I.

(a) Camshaft Bearings

To remove, proceed as follows

:-

(i)

Using a suitable tool, drift the

sealing disc out of the rear cam-

shaft bearing housing.

(ii)

Unscrew and remove the three

shouldered setscrews and plain

washers which retain the bearings

in position.

(iii)

Assemble the extracting tool and

adaptors into the cylinder block

as illustrated, and withdraw each

bearing in turn.

(b)

To

Fit

New Bearings

See Fig. 1 and observe the following:

The oil feed holes must be correctly

aligned and when drawing the bearings

into position

all

possible precautions

should be taken to ensure that these

do

not

turn

and so misalign the holes.

Ensure also that the locating hole in

each bearing is centrally disposed in

the tapped hole which accommodates

the locating screw. Failure to observe

this instruction may. result in the

bearing becoming distorted when the

locating screw is tightened.

Fit a plain steel washer of

h"

thickness

(1.588

mm.)

between the head of each

locating screw and the cylinder block.

Refit or replace the camshaft sealing

disc

if

necessary.

2.

ALUMINIUM PEDESTALS FOR

ROCKER SHAFT

New rocker pedestal brackets of aluminium

alloy were incorporated in normal produc-

tion at Engine No.

TS.12564E. The new

metal, by reason of its higher degree of

expansion when hot, enables the same

rocker clearances to be used for exhaust

valves as were previously applied only to

the inlets. This reduction in the exhaust

valve clearances has the advantage of

reducing

"

tappet

"

noise when the engine

is cold without any sacrifice of performance.

Where it is desired to fit the new pedestal

brackets, these should

be fitted as a

complete set, the part numbers being as

follows

:-

Aluminium Pedestal Bracket (Plain)

-

3 off-Part No. 112546

Aluminium Pedestal Bracket (Drilled)-

1 off -Part No. 112545

3.

PISTONS

From Engine No. TS.9731E, the pistons

are fitted with

:-

l Plain ring.

1 Taper ring.

1

Oil

scraper ring.

4.

COMBUSTION HEAD

To further improve performance,

"

High

Port" type combustion heads where in-

corporated in production at Engine No.

TS.9350E. In countries where high octane

fuel is unobtainable, the compression ratio

may be lowered to 7.511 by the use of a

compression plate, Part No. 200906. This

plate must be used in conjunction with a

steel

"

Corrojoint

"

gasket, Part No. 202775

in addition to the normal gasket.

When using this low compression plate it

wi!l also be necessary

to

use Champion

L.

10

sparking plugs gapped to 0.025" and special

push rods, Part No. 114048.

Loading...

Loading...