ENGINE

I.

GENERAL

DESCRIPTION

(Figs.

I

and

2)

The Engine

has four cylinders and

the overhead valves are push rod

operated, the 83

mm.

bore and 92

mm.

stroke give a capacity of 1,991 cubic

centimetres. The compression is 8.5

to 1.

A low compression kit (see page 27)

is available and reduces the com-

pression ratio to 7.5 to 1.

The Cylinder

Block

is an integral

casting in cast iron, the abutments for

the cylinder sleeves, the three rear

camshaft bearings and the crankshaft

bearing housings are machined in a

single unit. The main bearing housings

are line bore machined

;

the bearing

caps are not interchangeable and are

stamped together with the casting to

assist identification.

After Engine No.

9095E four Vander-

vel bi-metal bearings were fitted

to accommodate the camshaft.

A

recognition feature of engines so fitted

with these bearings will be that three

setscrews retaining the three rearmost

bearings will clearly be seen on the left-

hand side of the cylinder block. See

TR3 Supplement Engine Section

"B".

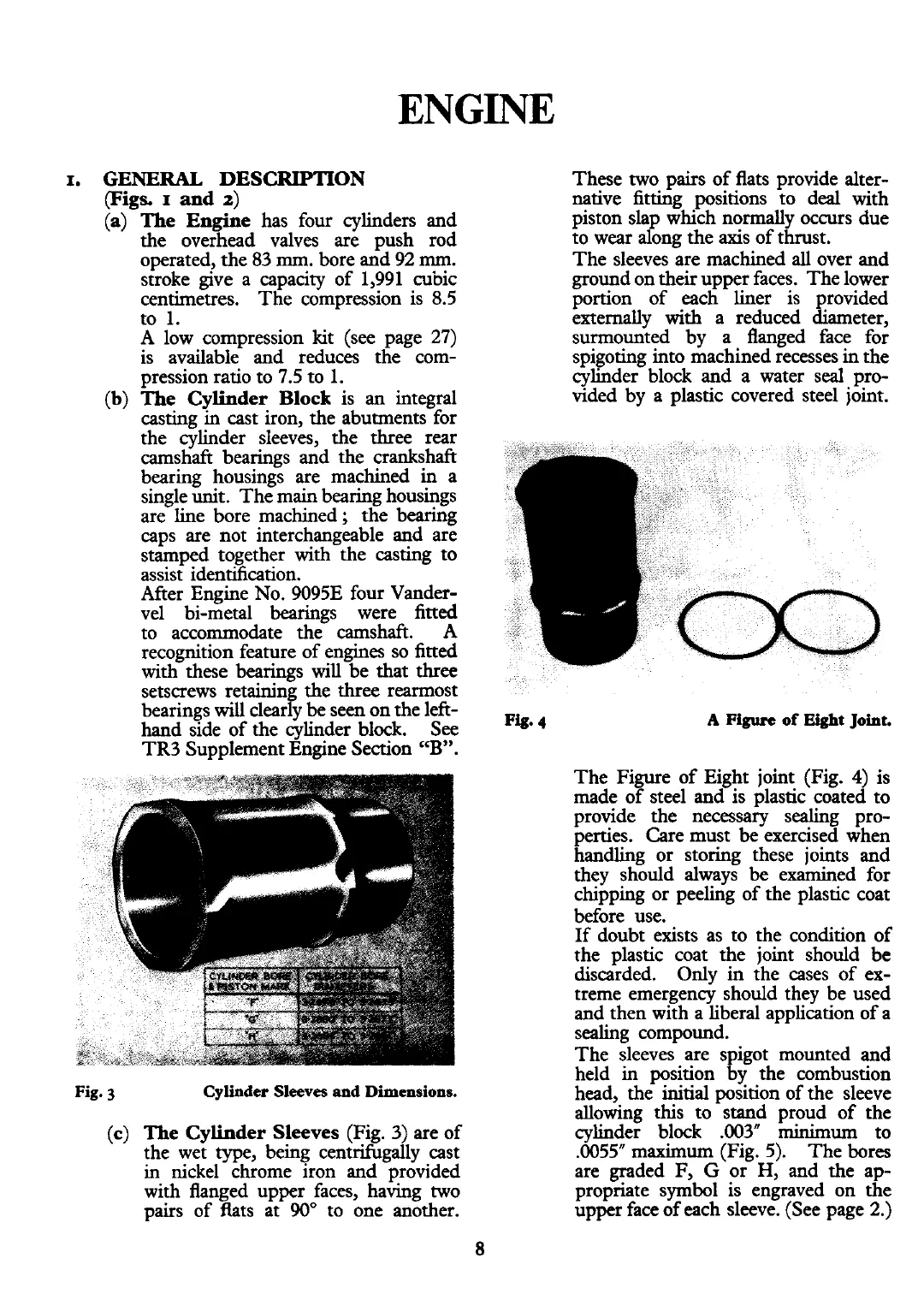

Fig.

3

Cylinder

Sleeves

and

Dimensions.

(c)

The Cylinder Sleeves

(Fig. 3) are of

the wet type, being centrifugally cast

in nickel chrome iron and provided

with flanged upper faces, having two

pairs of

fits at

90"

to one another.

These two pairs of flats provide alter-

native fitting positions to deal with

piston slap which normally occurs due

to wear along the axis of thrust.

The sleeves are machined

all

over and

ground on their upper faces. The lower

portion of each liner is provided

externally with a reduced diameter,

surmounted by a flanged face for

spigoting into machined recesses in the

cylinder block and a water seal pro-

vided by a plastic covered steel joint.

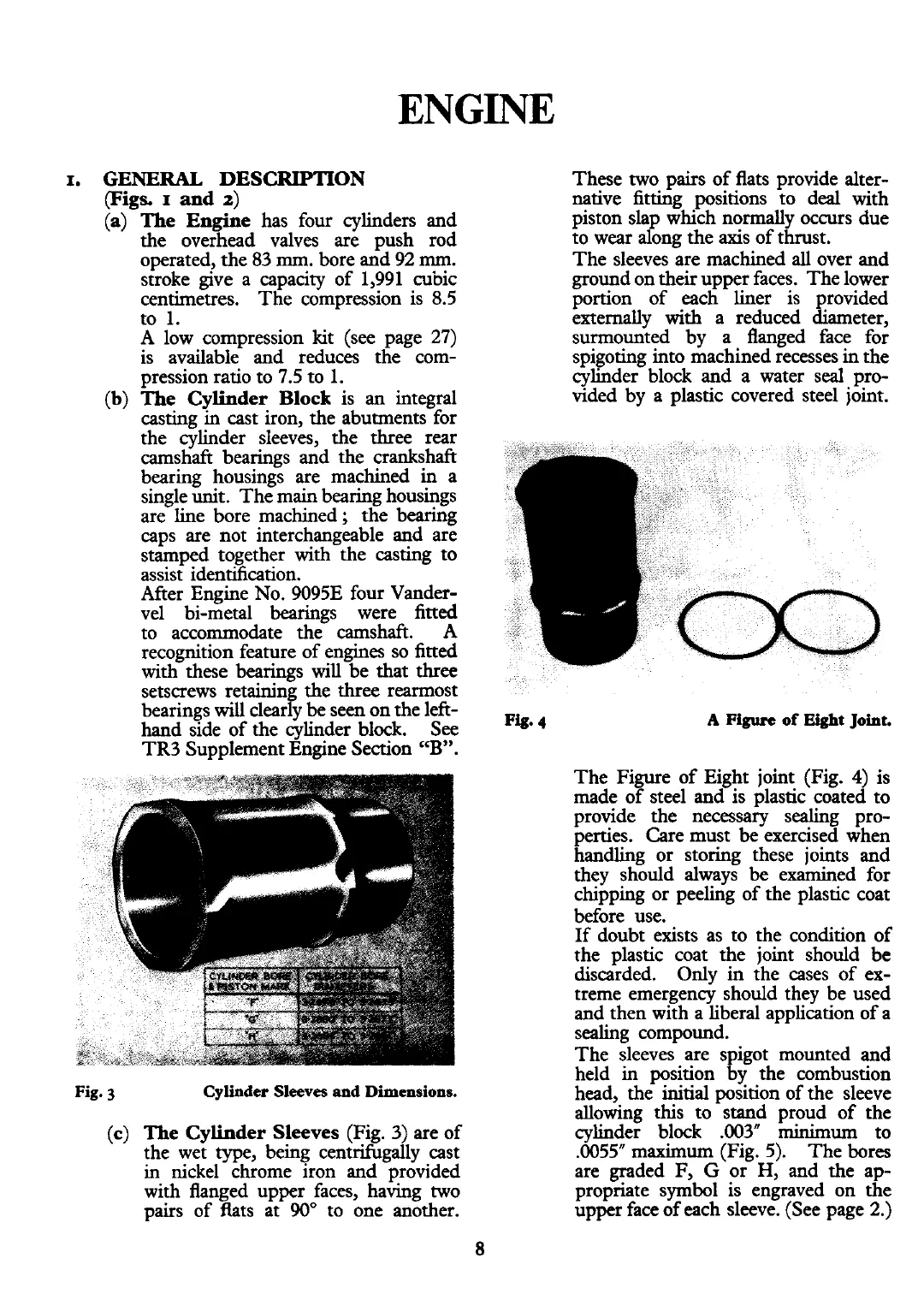

A

Figure

of

Eight

Joint.

The Figure of Eight joint (Fig.

4)

is

made of steel and is plastic coated to

provide the necessary sealing pro-

perties. Care must

be

exercised when

handling or storing these joints and

they should always be examined for

chipping or peeling of the plastic coat

before use.

If doubt exists as to the condition of

the plastic coat the joint should be

discarded. Only

in

the cases of ex-

treme emergency should they be used

and then with a liberal application of a

sealing compound.

The sleeves are spigot mounted and

held in position by the combustion

head, the initial position of the sleeve

allowing this to stand proud of the

cylinder block

.003"

minimum

to

.0055" maximum (Fig. 5).

The bores

are graded F,

G

or

H,

and the ap-

profiate symbol is engraved on the

upper face of each sleeve. (See page 2.)

Loading...

Loading...