ENGINE

Fig.

5

Checking

Cylinder Sleeve projection

above Cylinder Block.

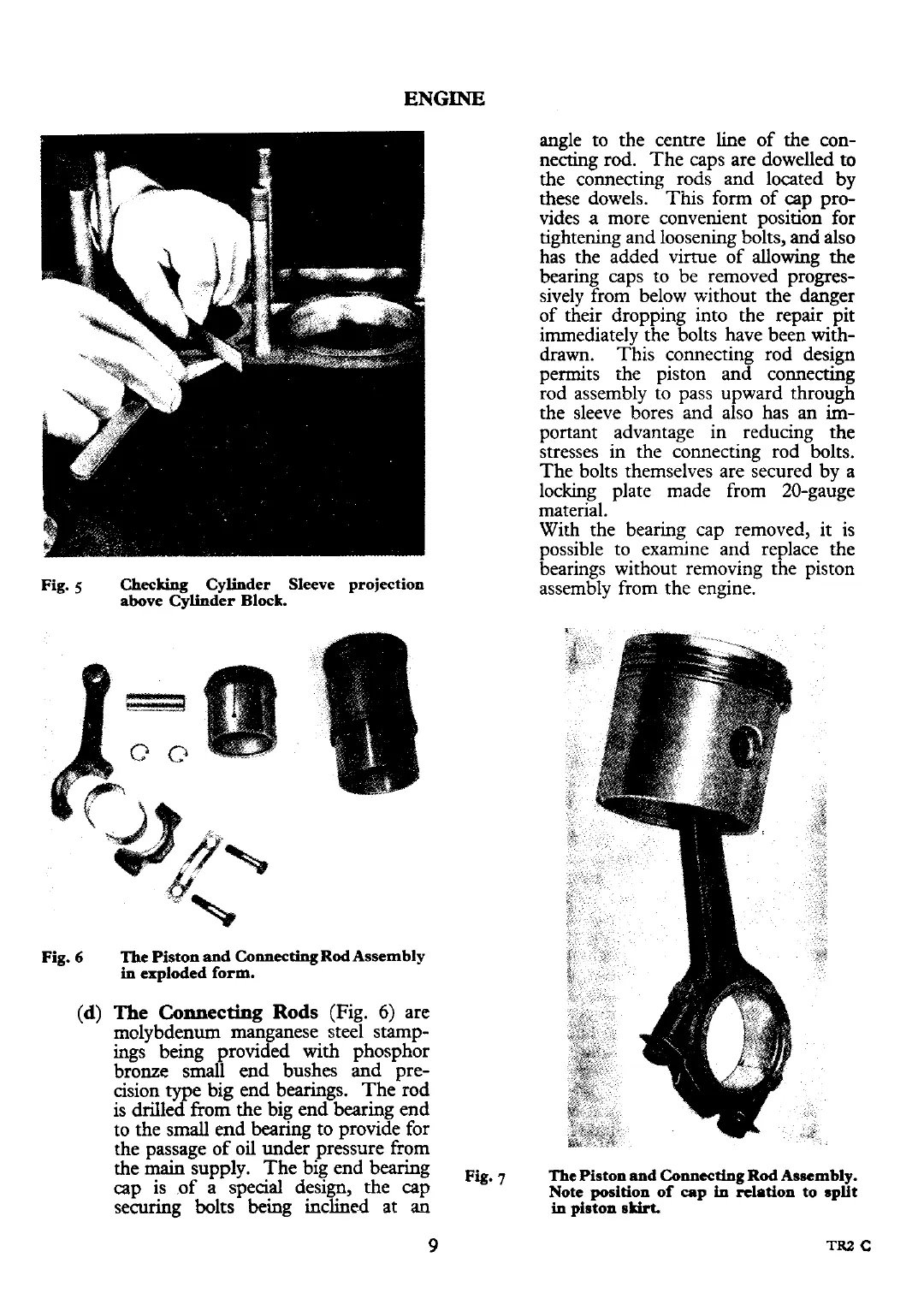

Fig.

6

The Piston and

Connecting

Rod Assembly

in

exploded form.

(d)

The

Connecting

Rods

(Fig.

6)

are

molybdenum manganese steel stamp-

ing~ being provided with phosphor

bronze small end bushes and pre-

cision type big end bearings. The rod

is drilled from the big end bearing end

to the small end bearing to provide for

the passage of oil under pressure

from

the main supply. The big end bearing

cap is of a special design, the cap

securing bolts being inclined at

an

angle to the centre line of the con-

necting rod. The caps are dowelled to

the

connecting rods and located by

these dowels. This form of cap pro-

vides

a

more convenient position for

tightening and loosening bolts,

and

also

has the added virtue of allowing the

bearing caps to be removed progres-

sively from below without the danger

of their dropping into the repair pit

immediately the bolts have been with-

drawn. This connecting rod design

permits the piston and connecting

rod assembly to pass upward through

the sleeve bores and also has an

im-

portant advantage in reducing the

stresses in the connecting rod bolts.

The bolts themselves are secured by a

locking plate made from 20-gauge

material.

With the bearing cap removed, it is

possible to examine and replace the

bearings without removing

the piston

assembly from the engine.

The

Piston and

Co~ectiag

Rod Assembly.

Note position of cap

h

relation to split

in

piston skirt.

Loading...

Loading...