ENGINE

(e) Aeroflex Compensating Pistons

(Fig

6)

are employed, which are made

from

a

special aluminium alloy and

each provided with two compression

rings and one oil scraper ring.

The pistons are graded F,

G

or

H

(dimensions on page

2)

and this symbol

is stamped on the crowns. The piston

skirt has a

h"

slot on the non-pressure

side and is fitted to the connecting rod

so that this slot is away from the point

of maximum thrust, Fig.

7

(facing the

camshaft side of the engine).

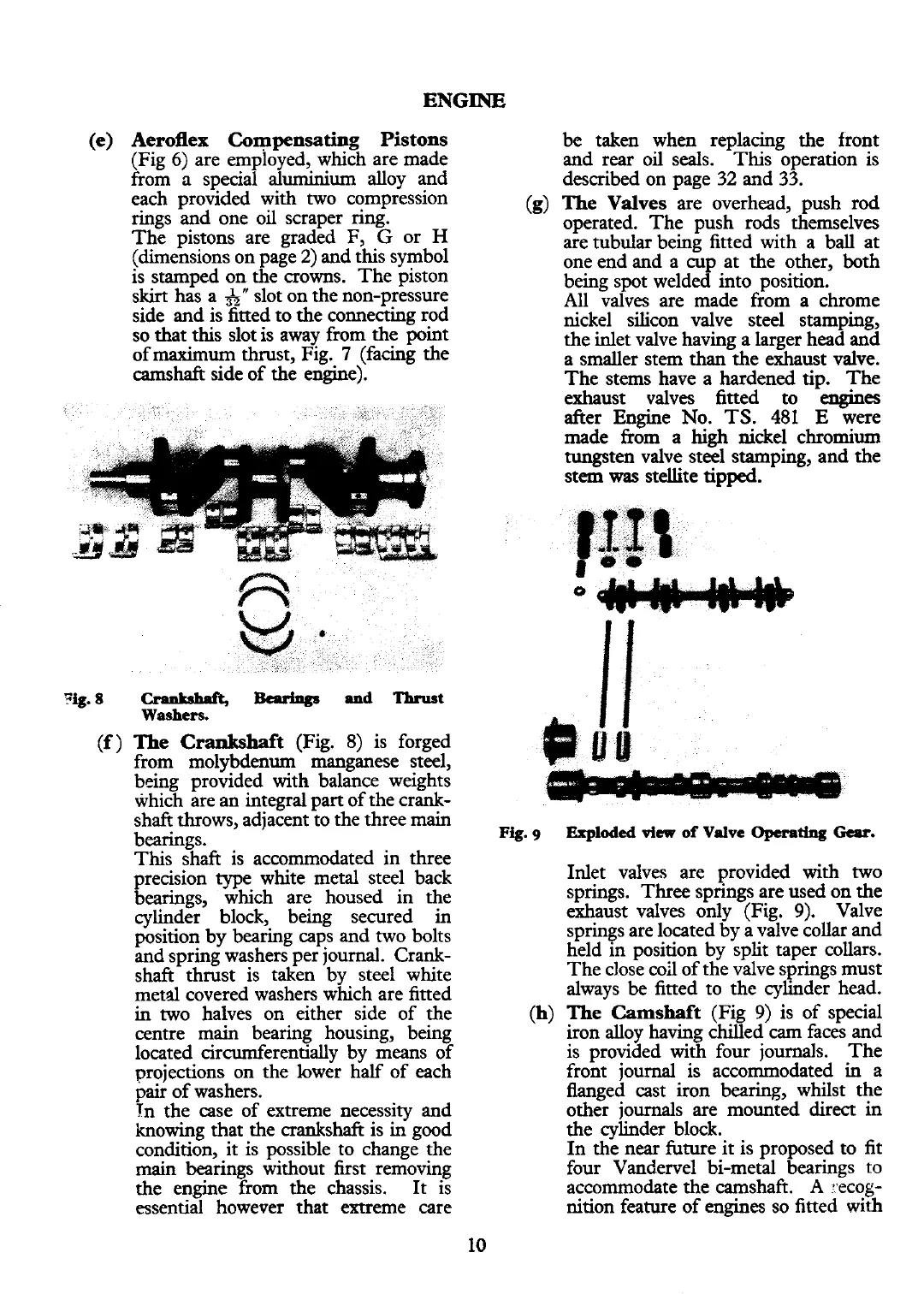

3g.8

CmnbhPtt,

Benring

and

Thrust

Washers.

(f)

The Crankshaft

(Fig. 8) is forged

from molybdenum manganese steel,

being provided with balance weights

which are

an

integral part of the crank-

shaft throws, adjacent to the three main

bearings.

This shafl is accommodated in three

precision type white metal steel back

bearings, which are housed in the

cylinder block, being secured in

position by bearing caps and two bolts

and spring washers per journal. Crank-

shaft thrust is taken by steel white

metal covered washers which are fitted

in two halves on either side of the

centre

main

bearing housing, being

located circumferentially by means of

projections on the lower half of each

pair

of washers.

Jn the case of extreme necessity and

knowing that the crankshaft is in good

condition, it is possible to change the

main

bearings

without first removing

the engine from the chassis. It is

essential however that extreme care

be taken when replacing the front

and rear oil seals.

This operation is

described on page

32

and

33.

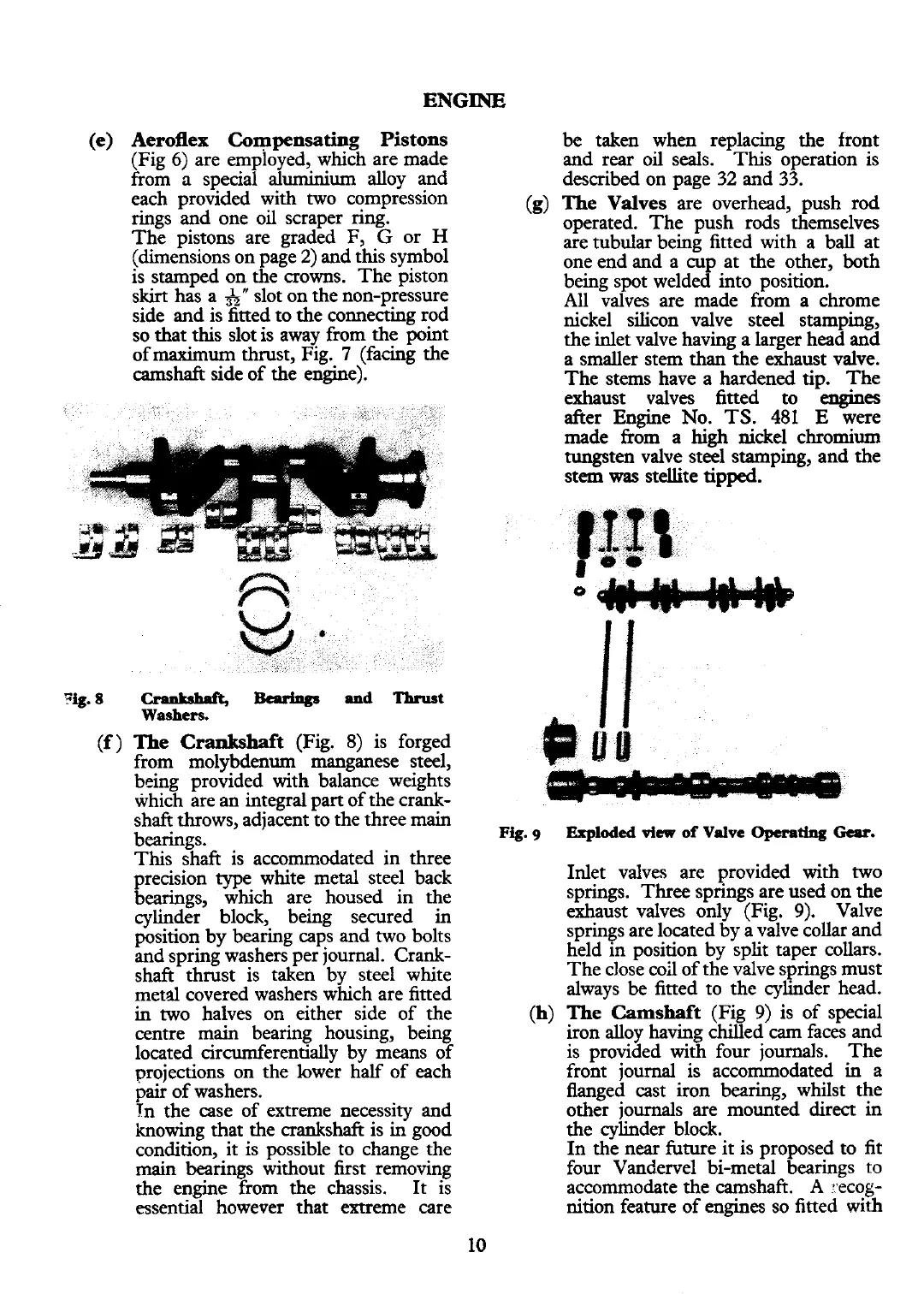

(g) The Valves

are overhead, push rod

operated. The push rods themselves

are tubular being fitted with a ball at

one end and a cup at the other, both

being spot welded into position.

All valves are made from a chrome

nickel silicon valve steel stamping,

the inlet valve having

a

larger head and

a smaller stem

than

the exhaust valve.

The stems have a hardened tip. The

exhaust valves fitted

to

-engines

after Engine No.

TS.

481

E

were

made from a

high

nickel chromium

tungsten valve steel stamping, and the

stem

was

stellite tipped.

Fig.

g

Exploded

view

of

Valve

Operating

Gear.

Inlet valves are provided with two

springs. Three springs are used on the

exhaust valves only (Fig.

9).

Valve

springs are located by a valve collar and

held in position by split taper collars.

The close

c02 of the valve springs must

always be fitted to the cylinder head.

(h)

The Camshaft

(Fig

9)

is of special

iron alloy having chilled

cam

faces and

is provided

with

four journals. The

front journal is accommodated

in

a

flanged cast iron bearing, whilst the

other journals are mounted

direct

in

the cylinder block.

In the near future it is proposed to fit

four

Vandervel bi-metal bearings

to

accommodate the camshaft. A *ecog-

nition feature of engines so fitted with

Loading...

Loading...