ENGINE

6.

PISTON ASSEMBLY AND

CYLPN-

The importance of using cylinder sleeve

DER SLEEVES

retainers to prevent relative movement of

The piston and cylinder bore dimensions

these parts is stressed.

are given on vage

2.

As indicated in this

list if tolera&i and limits, three sizes of

pistons are used in conjunction with suitable

bore dimensions. The three sizes of pistons

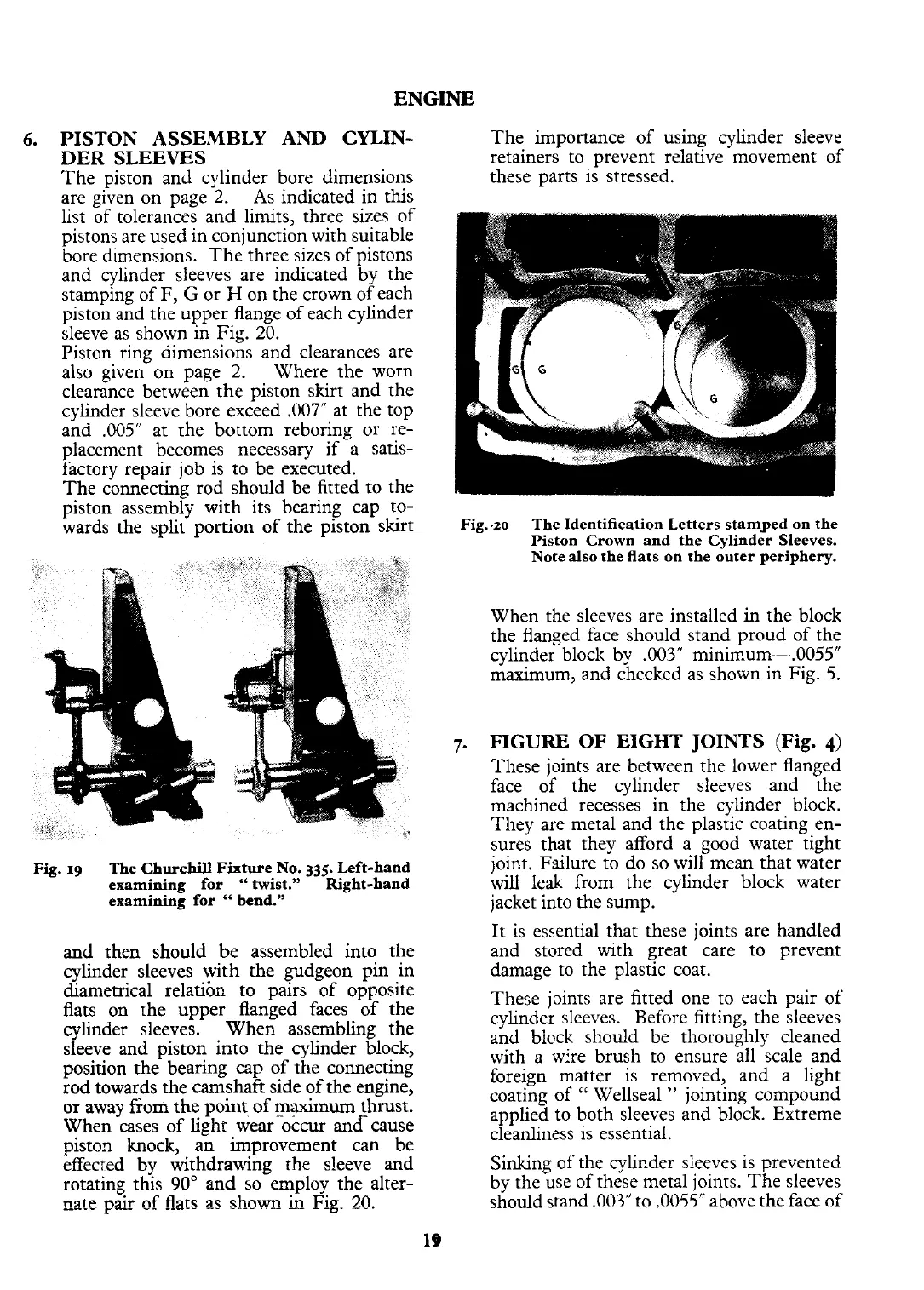

and cylinder sleeves are indicated by the

stamping of

F,

G

or

H

on the crown of each

piston and the upper flange of each cylinder

sleeve as shown in Fig.

20.

Piston ring dimensions and clearances are

also given on page

2.

Where the worn

clearance between the piston skirt and the

cylinder sleeve bore exceed

.007" at the top

and

.005"

at the bottom reboring or re-

placement becomes necessary if a satis-

factory repair job is to be executed.

The connecting rod should be fitted to the

piston assembly with its bearing cap to-

wards the split portion of the piston skirt

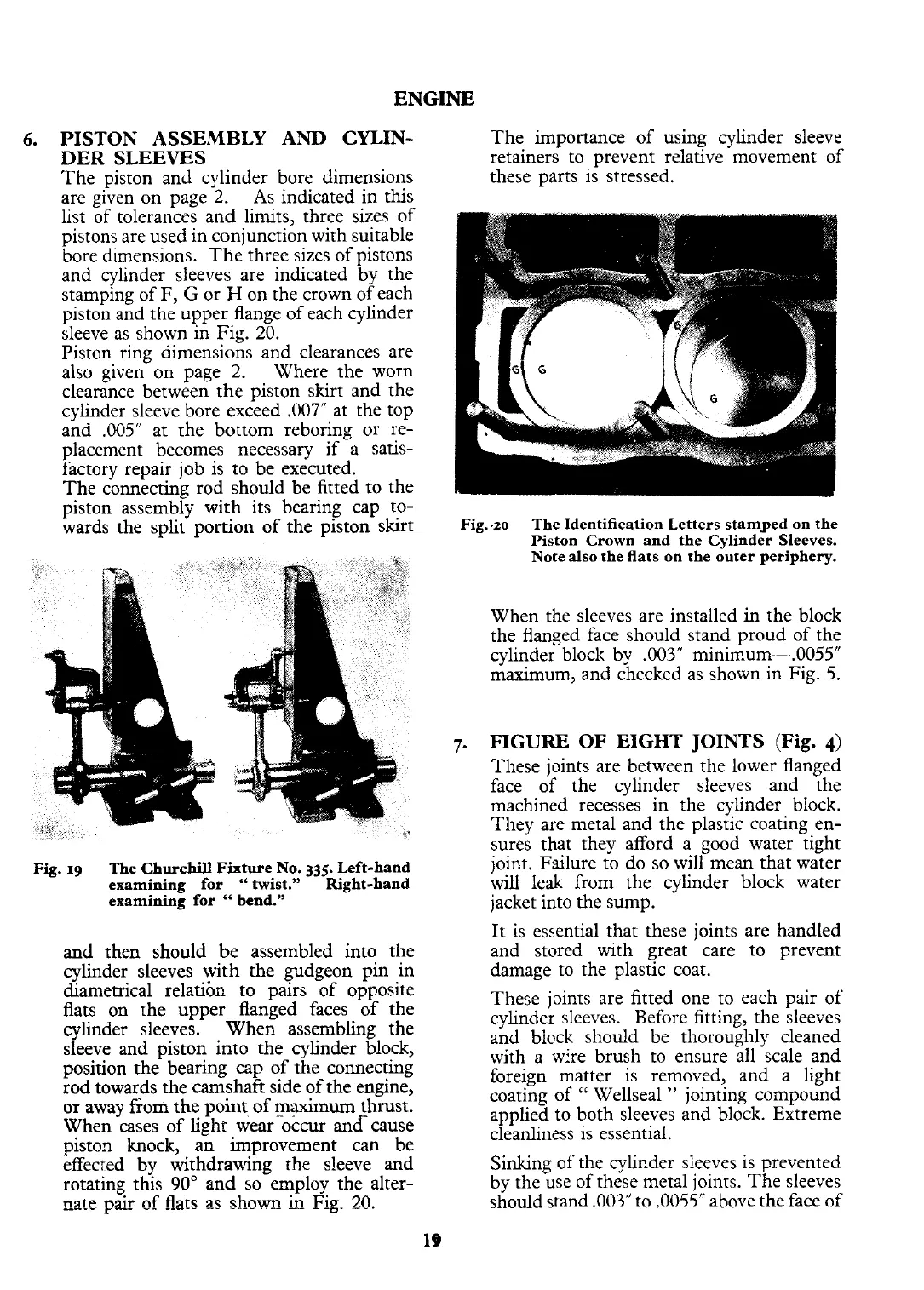

Fig.

19

The Churchill Fixture No.

335.

Left-hand

examining for

"

twist." Right-hand

examining for

"

bend."

and then should be assembled into the

cylinder sleeves with the gudgeon pin in

diametrical relatibr, to pairs of opposite

flats on the upper flanged faces of the

cylinder sleeves. When assembling the

sleeve and piston into the cylinder block,

position the bearing cap of the connecting

rod towards the

camshaft side of the engine,

or away from the point of

maximum

thrust.

When cases of light wear occur andcause

piston knock, an improvement can be

effecred by withdrawing the sleeve and

rotating this

90"

and so employ the alter-

nate pair

of

flats

as shown_

in

Fig.

2C).

Fig..zo

The Identification Letters stamped on the

Piston Crown and the Cylinder Sleeves.

Note also the flats on the outer periphery.

When the sleeves are installed in the block

the flanged face should stand proud of the

cylinder block by

.003"

minimum^--.0055"

maximum, and checked as shown in Fig.

5.

7.

FIGURE

OF

EIGHT JOINTS

(Fig.

4)

These joints are between the lower flanged

face of the cylinder sleeves and the

machined recesses in the cylinder block.

They are metal and the plastic coating en-

sures that they afford a good water tight

joint. Failure to do so will mean that water

will leak from the cylinder block water

jacket into the sump.

It is essential that these joints are handled

and stored with great care to prevent

damage to the plastic coat.

These joints are fitted one to each pair of'

cylinder sleeves. Before fitting, the sleeves

and block should be thoroughly cleaned

with a wire brush to ensure all scale and

foreign matter is removed, and a light

coating of

"

Wellseal

"

jointing compound

applied to both sleeves and block. Extreme

cleanliness is essential.

Sinking of the cylinder sleeves is prevented

by the use of these metal joints. The sleeves

shodd

stand

.003"

to

.0055"

above the

face

of

Loading...

Loading...