ENGINE

the cylinder block and a routine check

should be made whenever the combustion

head is removed. Should the cylinder

sleeve(s) be below the specified limits new

figure of eight joints should be fitted.

8.

CAMSHAFT

AND

TIMING

GEARS

The camshaft is of cast iron, having chilled

faces for the cams and journals. With the

camshaft a cast iron flanged front bearing is

used, the other three journals making direct

contact with the cylinder block.

In the near future it is proposed to fit

four Vandervel bi-metal bearings to ac-

commodate the camshaft

A

recognition of

an engine so fitted with these bearings

will

be that three setscrews retaining the three

rearmost bearings

will

be clearly visible on

the left-hand side of the cylinder block. The

front bearing is pressed into the front

bearing sleeve.

The camshaft is driven by a double roller

silent chain which engages with a sprocket

on the crankshaft and one spigotted on the

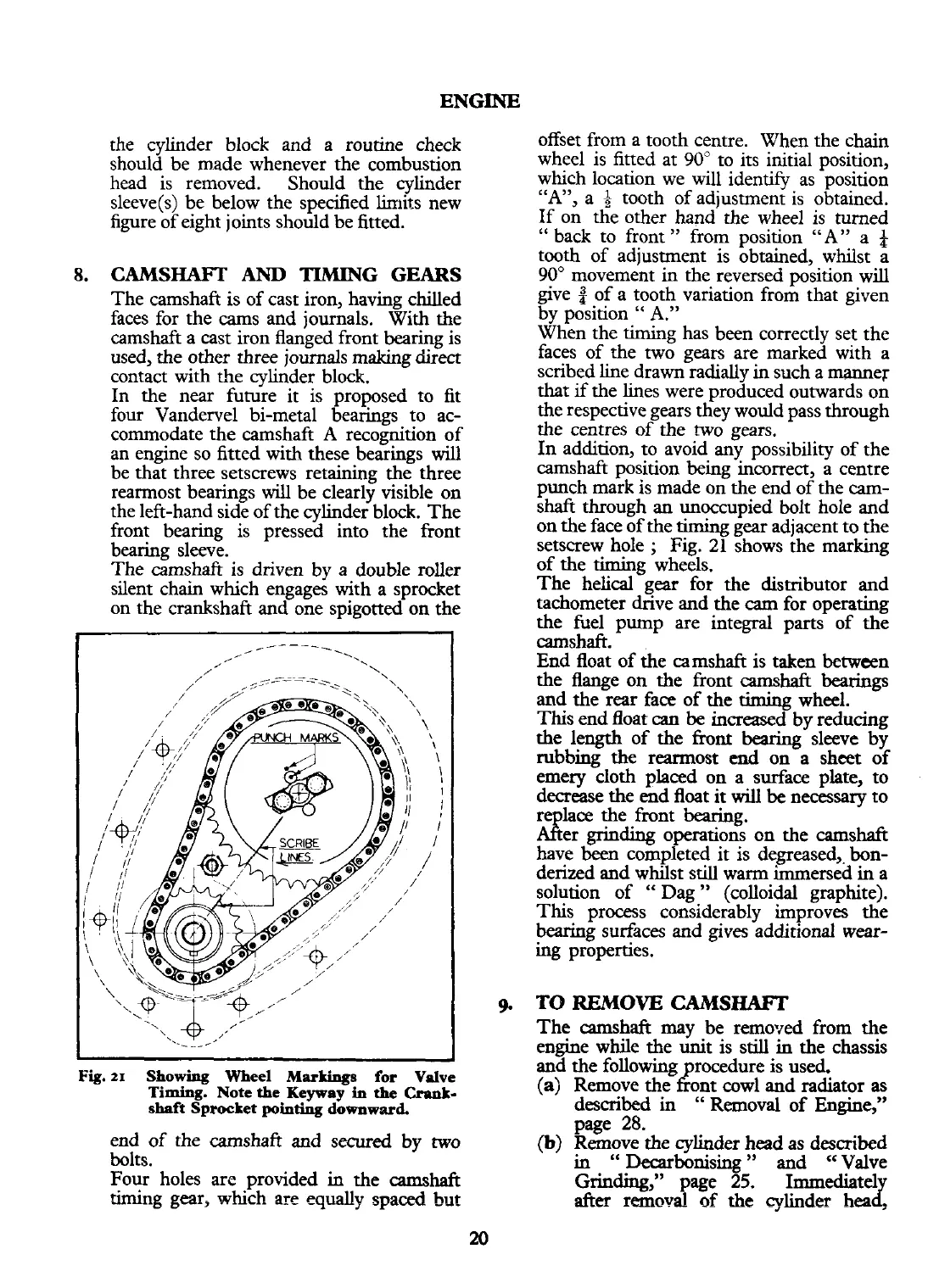

Fig.

21

Showing Wheel

Markiugs

for Valve

Timing.

Note the Keyway

in

the

Crank-

shaft Sprocket

pointing

downward

end of the camshaft and secured by two

bolts.

Four holes arc provided

in

the

camshaft

timing gear, which arc

equally

spaced hut

offset from a tooth centre. When the chain

wheel is fitted at

90"

to its initial position,

which location we will idenw as position

"

A",

a

3

tooth of adjustment is obtained.

If on the other hand the wheel is turned

"

back to front

"

from position "A" a

$

tooth of adjustment is obtained, whilst a

90"

movement in the reversed position will

give of a tooth variation from that given

by position

"

A."

When the timing has been correctly set the

faces of the two gears are marked with a

scribed line drawn radially in such a manner

that

if

the lines were produced outwards on

the respective gears they would pass through

the centres of the two gears.

In addition, to avoid any possibility of the

camshaft position being incorrect, a centre

punch mark is made on the end of the

cam-

shafi through an unoccupied bolt hole and

on the face of the

timing

gear adjacent to the

setscrew hole

;

Fig.

21

shows the marking

of the

timing

wheels.

The helical gear for the distributor and

tachometer drive and the

cam

for operating

the fuel pump are integral parts of the

camshaft.

End float of the camshaft is taken between

the flange on the front camshaft

bearings

and the rear face of the

timing

wheel.

This end float

can

be

increased by reducing

the length of the

hnt

bearing

sleeve by

rubbing

the

rearmost

end

on a sheet of

emery cloth placed on a surface plate, to

decrease the end float it will

be

necessary to

re

lace

the front

bearing.

ARer

grin-

operations on the camshaft

have

been

completed it is degreased,. bon-

derized and whilst still warm immersed

in

a

solution of

"

Dag

"

(colloidal graphite).

This process considerably improves the

bearing surfaces and gives additional wear-

ing

properties.

TO

REMOVE

CAMsm

The camshaft may

be

removed from the

engine while the unit is still

in

the chassis

and the following rocedure is used.

z

(a)

Remove the ont

cowl

and radiator as

described

in

"

Removal of

Eneine."

-

page

28.

(b)

Remove the cylinder head as described

in

"

Decarbonisine

"

and

cc

Valve

Grinding,"

page

55.

Immediate1

after

removal

of

the

cylinder

heaz

Loading...

Loading...