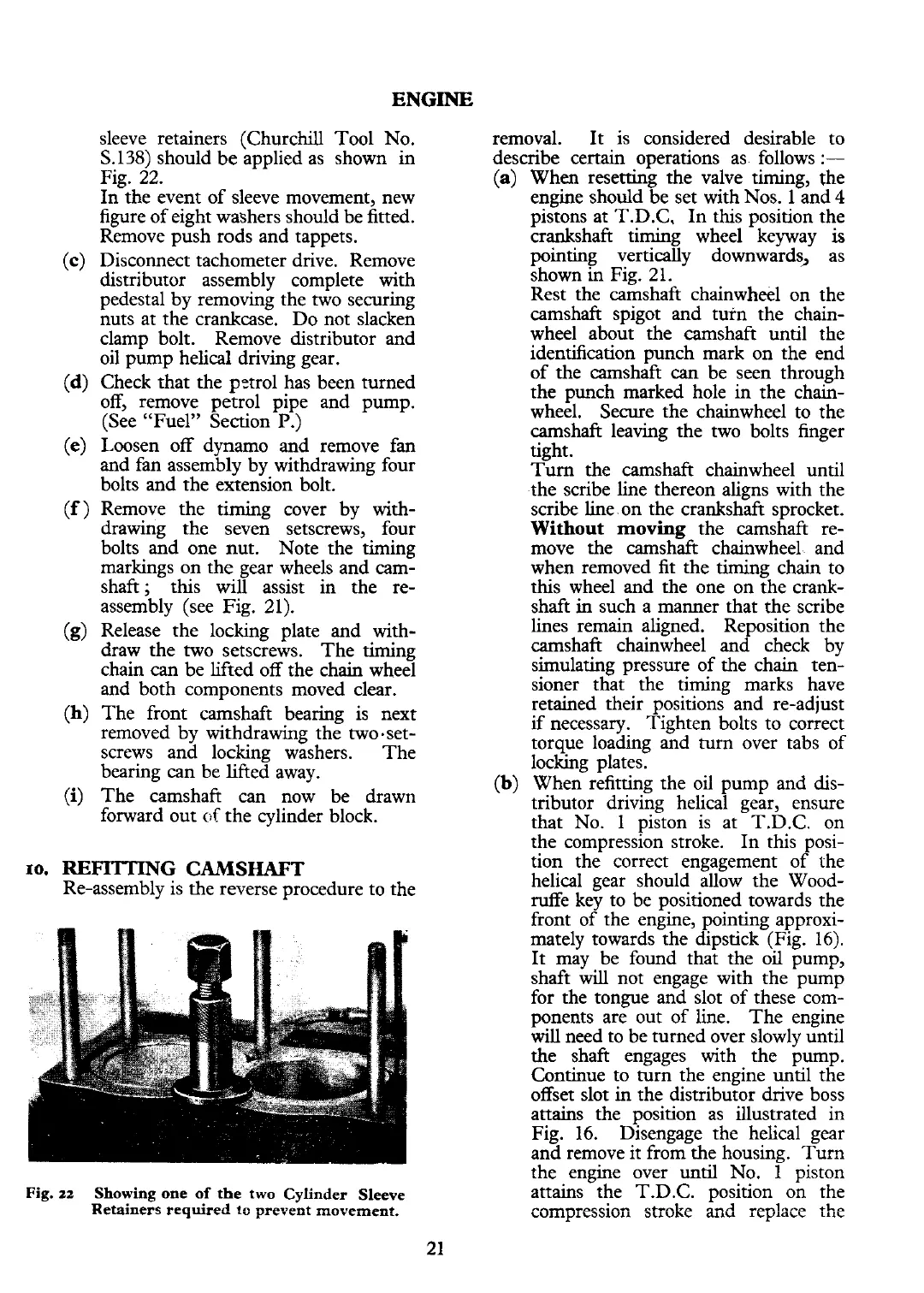

sleeve retainers (Churchill Tool No.

S.138)

should be applied as shown in

Fig. 22.

In the event of sleeve movement, new

figure of eight washers should be fitted.

Remove push rods and tappets.

Disconnect tachometer drive. Remove

distributor assembly complete with

pedestal by removing the two securing

nuts at the crankcase. Do not slacken

clamp bolt. Remove distributor and

oil pump helical driving gear.

Check that the

pctrol has been turned

off, remove petrol pipe and pump.

(See "Fuel" Section

P.)

Loosen off dynamo and remove fan

and fan assembly by withdrawing four

bolts and the extension bolt.

Remove the timing cover by with-

drawing the seven setscrews, four

bolts and one nut. Note the timing

markings on the gear wheels and cam-

shaft; this will assist in the

re-

assembly (see Fig. 21).

Release the locking plate and

with-

draw the two setscrews. The timing

chain

can

be lifted off the chain wheel

and both components moved clear.

The front camshaft bearing is next

removed by withdrawing the two-set-

screws and locking washers. The

bearing can be lifted away.

-

The camshaft

can

now be drawn

forward out

of

the cylinder block.

10.

REFITTING

CAMSHAFT

Re-assembly is the reverse procedure to the

Fig.

zz

Showing one of the two Cylinder Sleeve

Retainers required

t=

prevent movement.

removal. It is considered desirable to

describe certain operations as follows

:-

(a)

When resetting the valve timing, the

engine should be set with Nos. 1 and

4

pistons at T.D.C, In this position the

crankshaft timing wheel keyway

is

pointing vertically downwards, as

shown in Fig. 21.

Rest the camshaft chainwheel on the

camshaft spigot and turn the chain-

wheel about the camshaft until the

identification punch mark on the end

of the camshaft

can

be seen through

the punch marked hole in the chain-

wheel. Secure the chainwheel to the

camshaft leaving the two bolts finger

-

tight.

Turn

the camshaft chainwheel until

the scribe line thereon aligns with the

scribe line on the crankshaft sprocket.

Without moving

the camshaft re-

move the camshaft chainwheel and

when removed

fit

the timing chain to

this wheel and the one on the crank-

shaft in such a manner that the scribe

lines remain aligned. Reposition the

camshaft chainwheel and check by

simulating pressure of the chain

ten-

sioner that the timing marks have

retained their positions and re-adjust

if

necessary. Tighten bolts to correct

torque loading and turn over tabs of

locking plates.

(b)

When refitting the oil pump and dis-

tributor driving helical gear, ensure

that No. 1 piston is at T.D.C. on

the compression stroke. In this posi-

tion

the correct engagement of the

helical gear should allow the

Wood-

ruffe key to be positioned towards the

front of the engine, pointing approxi-

mately towards the dipstick (Fig.

16).

It may be found that the oil pump,

shaft

will

not engage with the pump

for the tongue and slot of these com-

ponents are out of line. The engine

will

need to be turned over slowly until

the shaft engages with the pump.

Continue to turn the engine until the

offset slot in the distributor drive boss

attains the position as illustrated in

Fig. 16. Disengage the helical gear

and remove it from the housing. Turn

the engine over until No.

1

piston

attains the T.D.C. position on the

compression stroke

and

replace

:he

Loading...

Loading...