ENGINE

helical gear when the shaft

will

engage

with the oil pump.

(c)

Having refitted the cylinder head and

rocker shaft it is advisable to apply oil

to the ground surfaces where the

rockers contact the valves, as these

points do not immediately receive a

supply of oil.

11.

TO SET

VALVE

CLEARANCES

111

All adjustments should be made when the

engine is cold.

(a)

Remove the rocker cover from the

engine.

(b)

Turn the engine over by hand until

the valves of any cylinder are on the

point of rock. Note the number of this

1

cylinder.

(c)

Continue turning the engine for

another complete revolution, this

will

ensure that the tappets of this cylinder

I

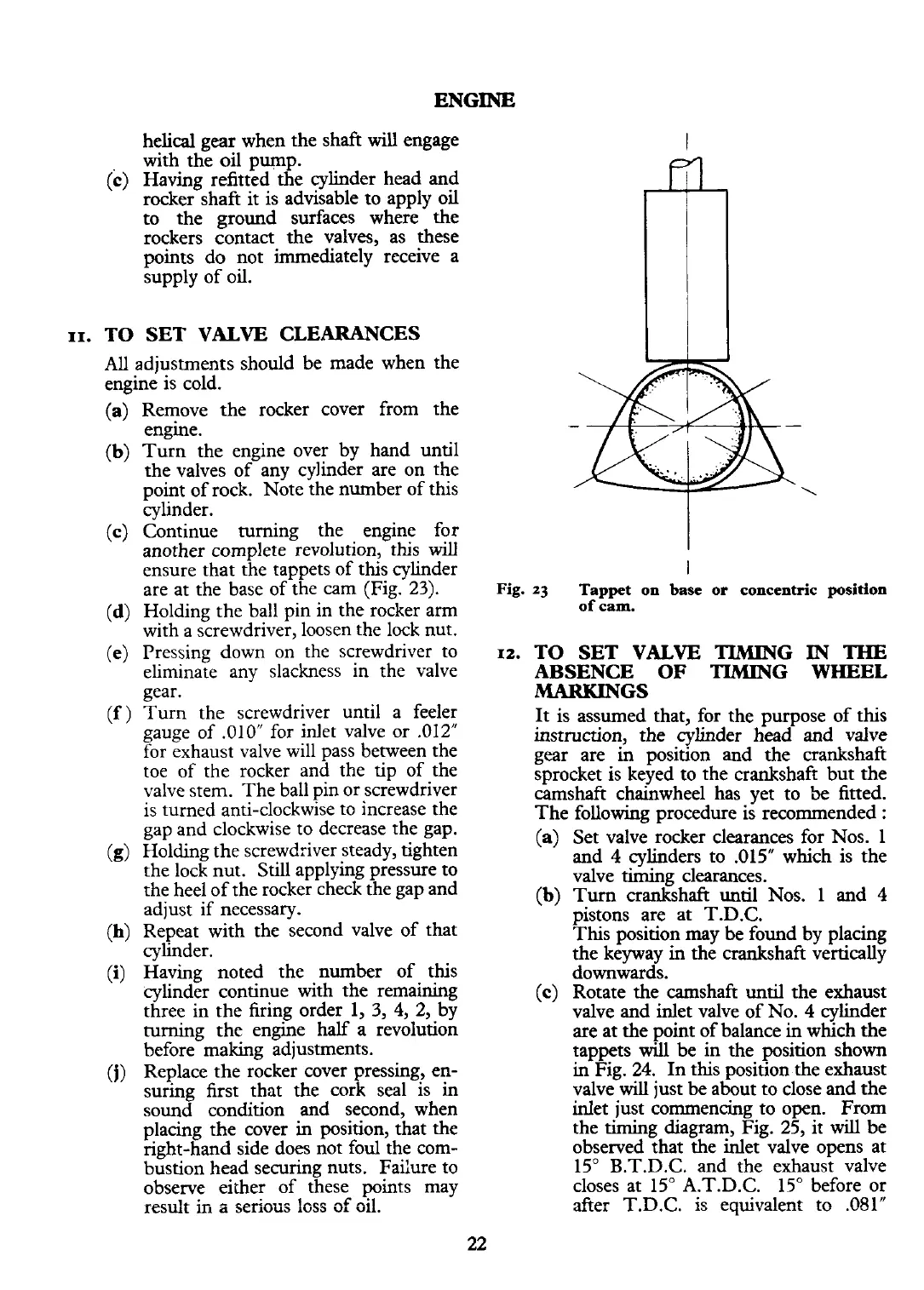

are at the base of the cam (Fig.

23).

Fig.

23

Tappet on base or concentric position

(d)

Holding the ball pin in the rocker arm

of cam.

with a screwdriver, loosen the lock nut.

(e)

Pressing down on the screwdriver to

12.

TO

SET

VALVE

TIMING

IN

THE

eliminate any slackness in the valve

ABSENCE OF

TIMING

WHEEL

gear.

MARKINGS

(f)

Turn the screwdriver until a feeler

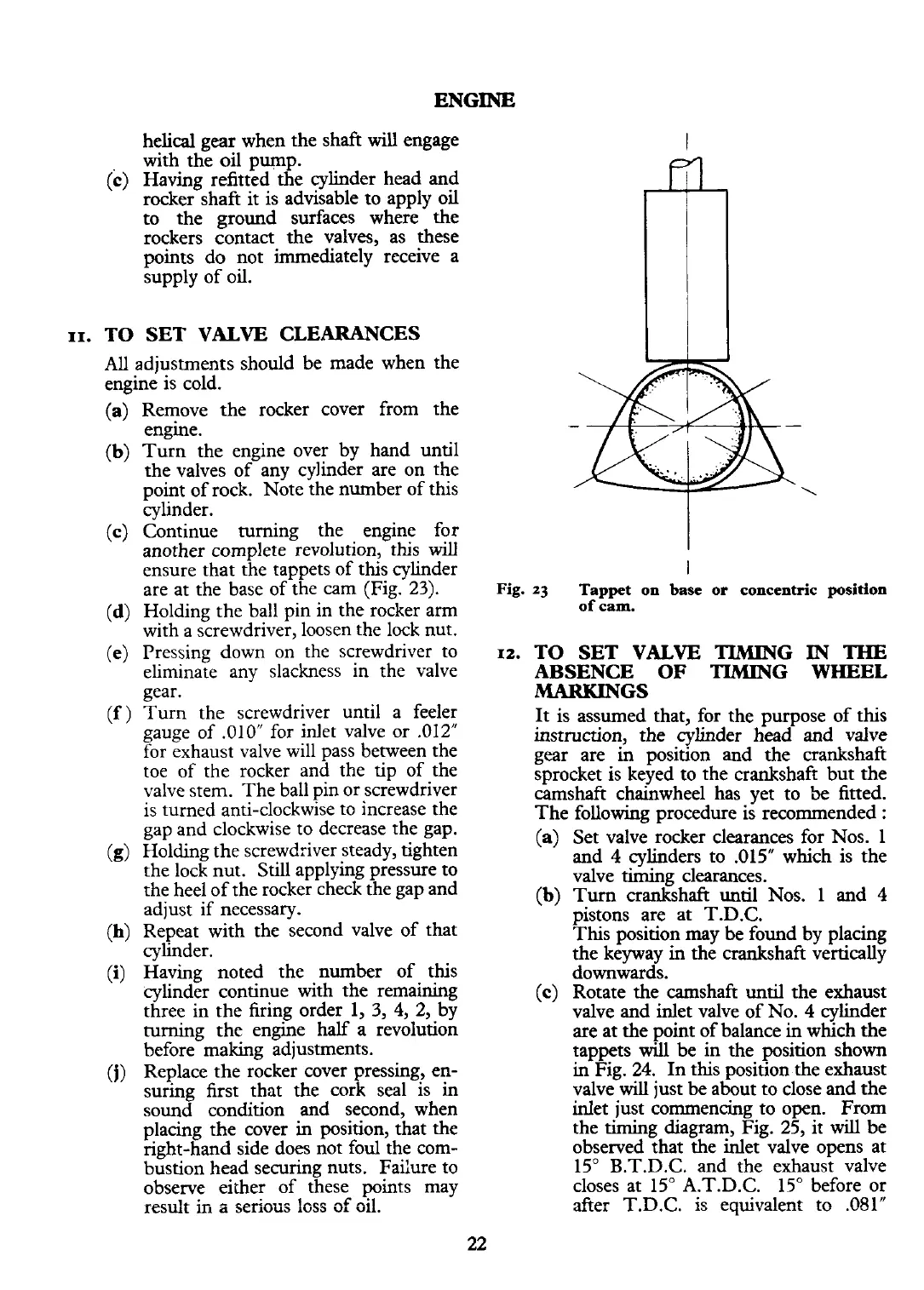

It is assumed that, for the purpose of this

gauge of

.010"

for inlet valve or

,012"

instruction, the cylinder head and valve

for exhaust valve will pass between the

gear are in position and the crankshaft

toe of the rocker and the tip of the

sprocket is keyed to the crankshaft but the

valve stem. The ball pin or screwdriver

camshaft chainwheel has yet to

be

fitted.

is turned anti-clockwise to increase the

The following procedure is recommended

:

gap and clockwise to decrease the gap.

(a)

Set valve rocker clearances for Nos. 1

(g)

Holding the screwdyiver steady, tighten

and 4 cylinders to .015" which is the

the lock nut.

Still

applying pressure to

valve timing clearances.

the heel of the rocker check the gap and

(b)

Turn crankshaft until Nos. 1 and 4

adjust if necessary.

pistons are at

T.D.C.

(h)

Repeat with the second valve of that

This position may be found by placing

cylinder.

the keyway in the crankshaft vertically

(i)

Having noted the number of this downwards.

cylinder continue with the remaining

(c)

Rotate the camshaft until the exhaust

three in the firing order 1,

3,

4, 2, by

valve and inlet valve of No. 4 cylinder

turning the engine half a revolution

are at the point of balance in which the

before making adjustments.

tappets

will

be

in the position shown

(j)

Replace the rocker cover pressing, en-

in

Fig. 24. In this position the exhaust

suring first that the cork seal is in

valve

will

just be about to close and the

sound condition and second, when inlet just commencing to open. From

placing the cover in position, that the the timing diagram, Fig. 25, it

will

be

right-hand side does not foul the com- observed that the inlet valve opens at

bustion head securing nuts. Failure to 15" B.T.D.C. and the exhaust valve

observe either of these points may

closes at

15" A.T.D.C.

15"

before or

result

in

a

serious loss

of

oil. &!er T.D.C. is equivalent to .081"

22

Loading...

Loading...