ENGINE

(2.06

mm.)

piston travel or

1.5"

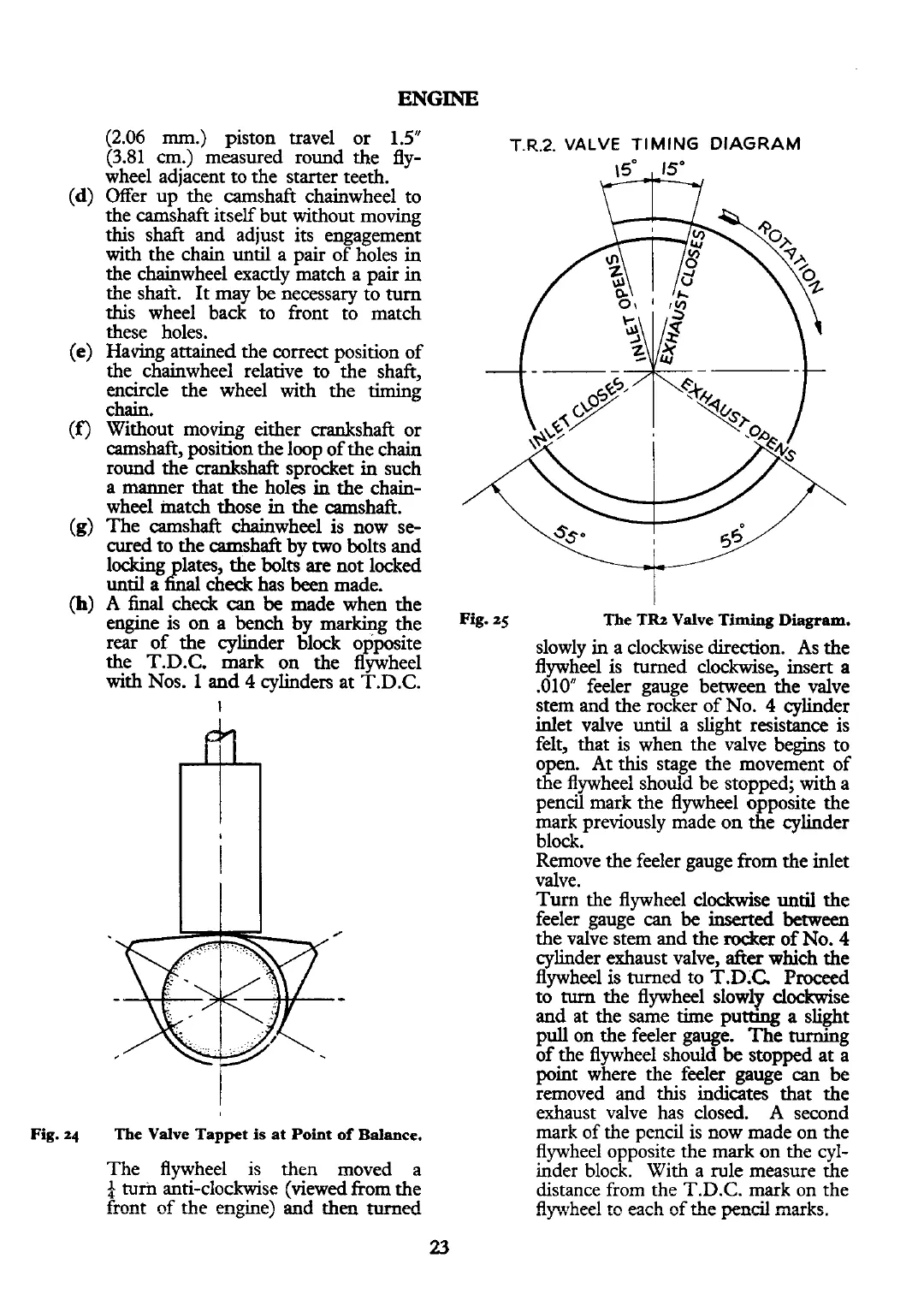

T

R.2.

VALVE

TIMING

DIAGRAM

(3.81

cm.)

measured round the fly-

wheel adjacent to the starter teeth.

(d)

Offer up the camshaft chainwheel to

the camshaft itself but without moving

this shaft and adjust its engagement

with the chain

until

a pair of holes in

the chainwheel exactly match a pair in

the

shart. It may

be

necessary to turn

this wheel back to front to match

these holes.

(e)

Having attained the

correct

position of

the chainwheel relative to the shaft,

encircle the wheel

with

the timing

chain.

(f)

Without moving either crankshaft or

camshaft, position the loop of the chain

round the crankshaft sprocket in such

a manner that the holes in the chain-

wheel match those

in

the camshaft.

(g)

The camshaft chainwheel

is

now se-

cured to the camshaft by two bolts and

locking lates, the bolts

are

not locked

until a

&l

check has

been

made.

I

(h)

A

final

check

can

be

made when the

I

engine is on a bench by marking the

Fig.

25

The

TR2

Valve

Timing

Diagram.

rear of the cylinder block opposite

slowly in a clockwise direction. As the

the T.D.C. mark on the flywheel

flywheel is turned clockwise, insert

a

with

Nos.

1

and

4

cylinders at T.D.C.

.010" feeler gauge between the valve

I

stem and the rocker of No.

4

cylinder

inlet valve

until

a slight resistance is

felt, that is when the valve begins to

open. At this stage the movement of

the flywheel should be stopped;

with

a

pencil mark the flywheel opposite the

mark previously made on the cylinder

block.

Remove the feeler gauge from the inlet

valve.

Turn the flywheel clockwise

until

the

feeler gauge

can

be

inserted

between

the valve stem and the

&er

of

No.

4

cylinder exhaust valve,

after

which the

flywheel is turned to T.D.C. Proceed

to

turn

the flywheel slow17 clockwise

and at the same time pumng a slight

pull on the feeler gauge. The

tuming

of the flywheel should

be

stopped at a

l

point where the feeler gauge

can

be

removed and this indicates that the

exhaust valve has closed.

A

second

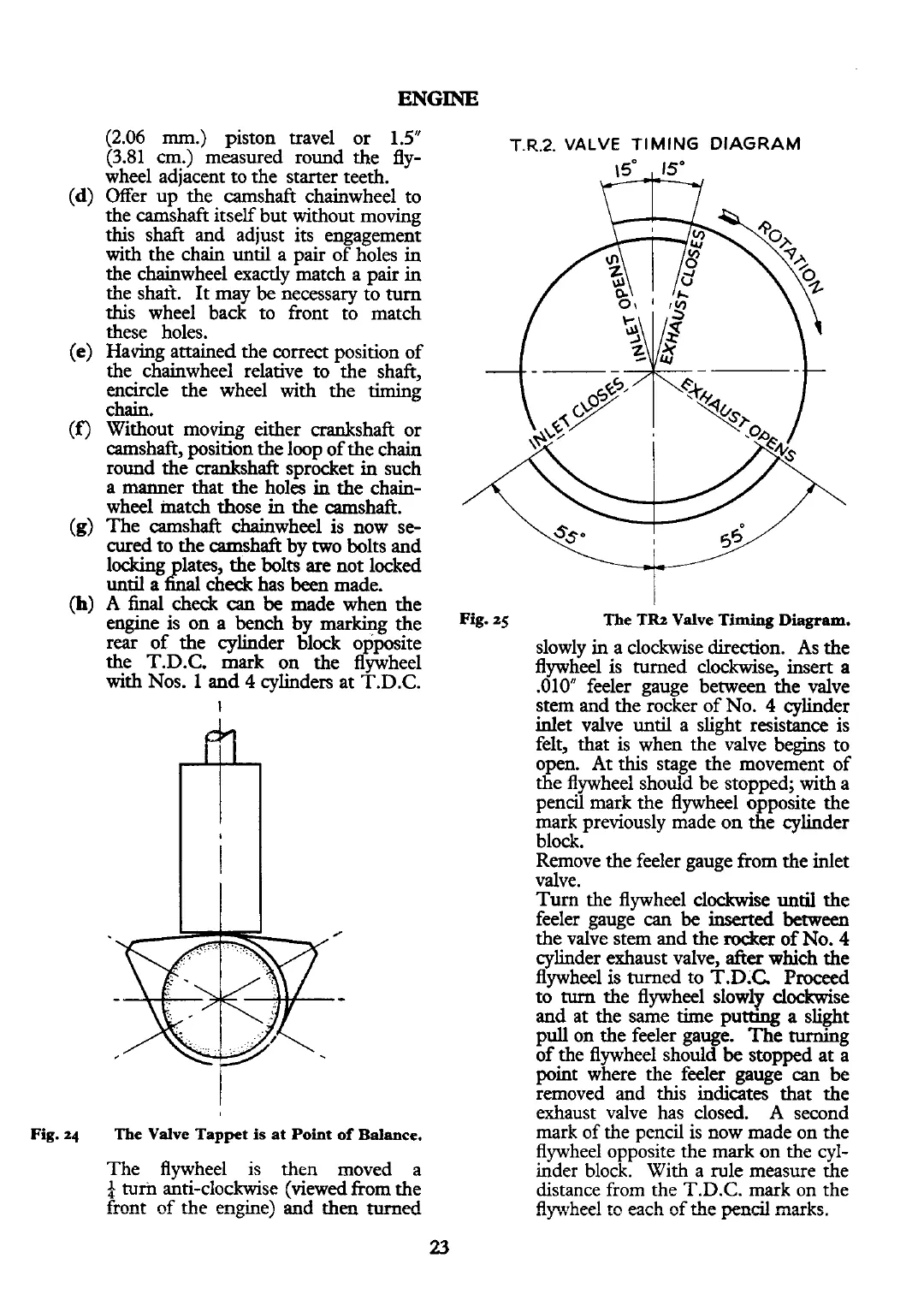

Fig.

24

The

Valve

Tappet

is

at

Point

of

Balance.

mark of the pencil is now made on the

flywheel opposite the mark on the cyl-

The flywheel is then moved

a

inder block. With a rule measure the

4

turn

anti-clockwise (viewed from the distance from the T.D.C. mark on the

front

of

the

e~gine) and

theo

turned

fiywhee!

cc

each ef &e

pencil

marks.

23

Loading...

Loading...