ENGINE

arises, it is important that the valve guides

are concentric with the seats themselves.

Where a valve guide is badly worn it should

be replaced before the seat is

recut.

While refacing valves, only remove suffi-

cient metal to clean up the face, otherwise

if too much is removed the edge

will

tend

to curl up in service.

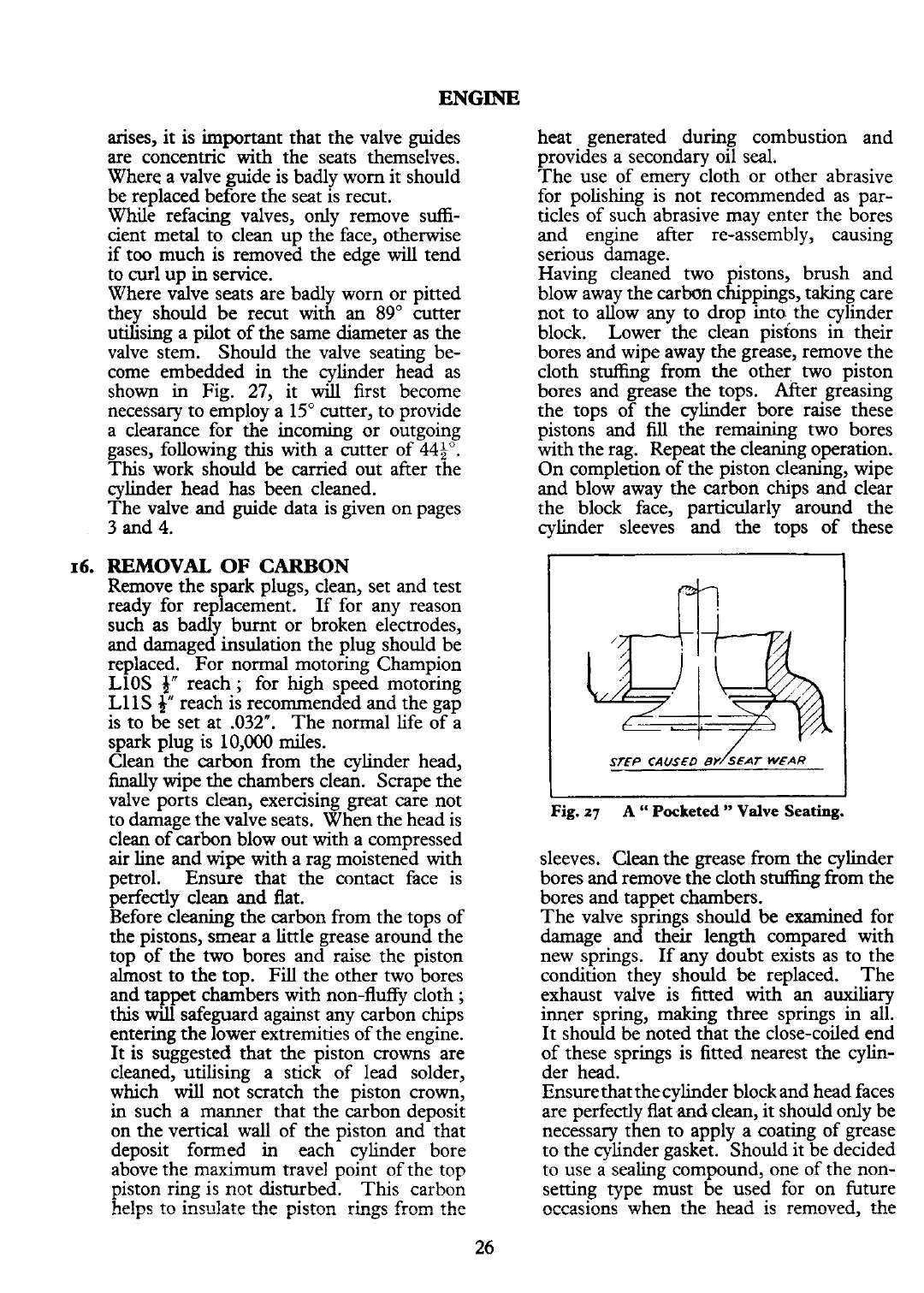

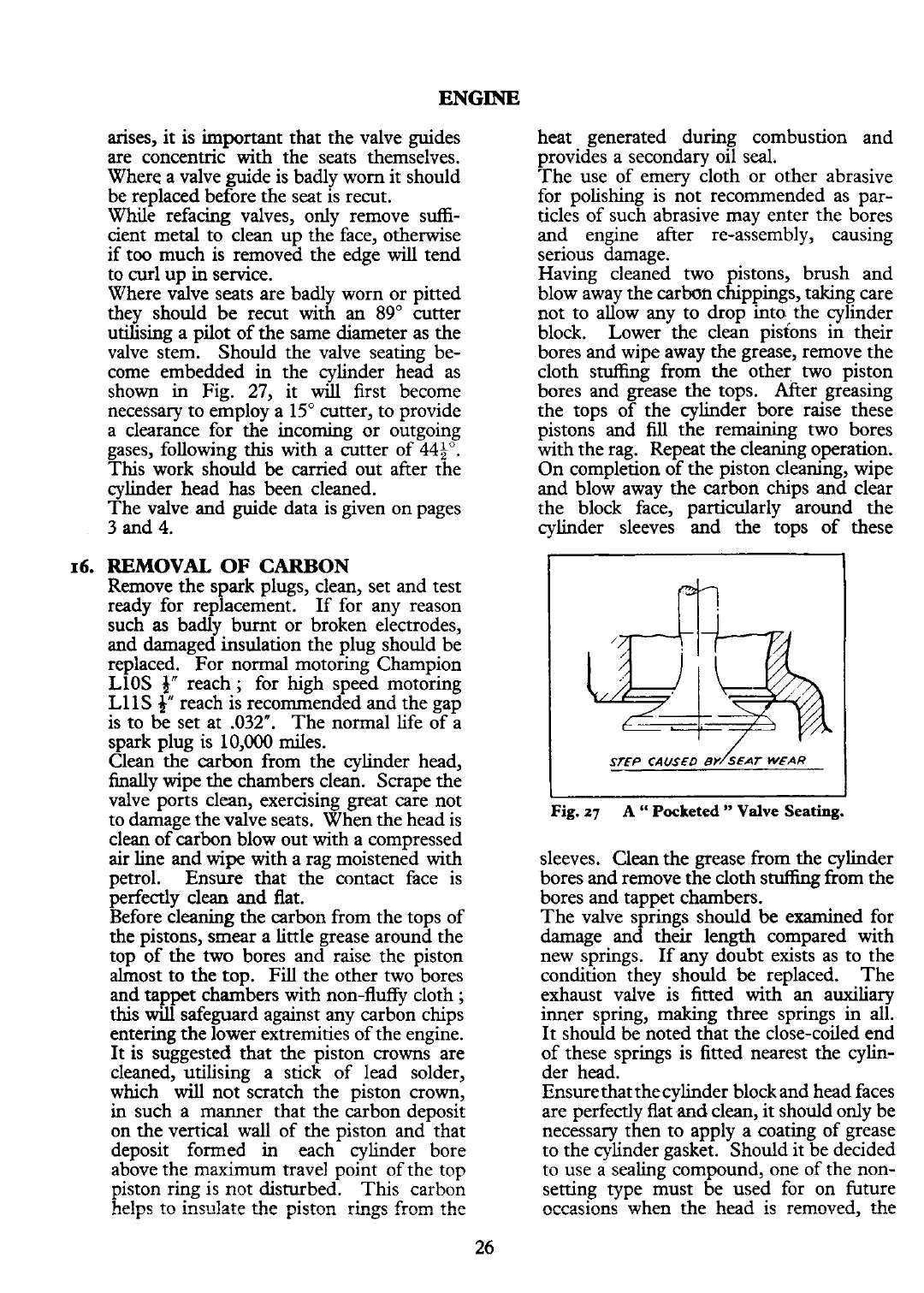

Where valve seats are badly worn or pitted

they should be

recut with an

89"

cutter

utilising a pilot of the same diameter as the

valve stem. Should the valve seating be-

come embedded in the cylinder head as

shown in Fig. 27, it

will

first become

necessary to employ a 15" cutter, to provide

a clearance for the incoming or outgoing

gases, following this with a cutter of

449".

This work should

be

carried out after the

cylinder head has been cleaned.

The valve and guide data is given on pages

3

and

4.

16.

REMOVAL

OF

CARBON

Remove the spark plugs, clean, set and test

ready for replacement. If for any reason

such as badly burnt or broken electrodes,

and damaged insulation the plug should be

replaced. For normal motoring Champion

LlOS

f"

reach

;

for high speed motoring

L1

l

S

f"

reach is recommended and the gap

is to be set at .032". The normal life of a

spark plug is

10,000

miles.

Clean the carbon from the cylinder head,

finally wipe the chambers clean. Scrape the

valve ports

clean,

exercising great care not

to damage the valve seats. When the head is

clean of carbon blow out with a compressed

air

line and wipe with a rag moistened with

petrol. Ensure that the contact face is

perfectly clean and flat.

Before cleaning the carbon from the tops of

the pistons, smear a little grease around the

top of the two bores and raise the piston

almost to the top. Fill the other two bores

and tappet chambers with non-fluffy cloth

;

this

will

safeguard against any carbon chips

entering the lower extremities of the engine.

It is suggested that the piston crowns are

cleaned, utilising a stick of lead solder,

which

will

not scratch the piston crown,

in such a manner that the carbon deposit

on the vertical wall of the piston and that

deposit formed in each cylinder bore

above the maximum travel point of the top

piston ring is not disturbed. This carbon

h~!nr

incrrlgt~ thp njctnn rinuc

frnm

the

r

---------

---

r

-----

---

a-

-----

---

heat generated during combustion and

provides a secondary oil seal.

The use of emery cloth or other abrasive

for polishing is not recommended as par-

ticles of such abrasive may enter the bores

and engine after re-assembly, causing

serious damage.

Having cleaned two pistons, brush and

blow away the carbon chippings, taking care

not to allow any to drop into the cylinder

block. Lower the clean pistons in their

bores and wipe away the grease, remove the

cloth

stuffing from the other two piston

bores and grease the tops. After greasing

the tops of the cylinder bore raise these

pistons and

lill

the remaining two bores

with the rag. Repeat the cleaning operation.

On completion of the piston cleaning, wipe

and blow away the carbon chips and clear

the block face, particularly around the

cylinder sleeves and the tops of

'

these

Fig.

27

A

"

Pocketed

"

Valve

Seating.

sleeves. Clean the grease from the cylinder

bores and remove the cloth stuffing from the

bores and tappet chambers.

The valve springs should be examined for

damage and their length compared with

new springs. If any doubt exists as to the

condition they should

be

replaced. The

exhaust valve is fitted with an auxiliary

inner spring, making three springs in all.

It

should be noted that the close-coiled end

of these springs is fitted nearest the cylin-

der head.

Ensure that thecylinder block and head faces

are

~erfectlv flat

and

clean. it should onlv be

nec&sary then to apply a'coating of .g&ase

to the cylinder gasket. Should it be decided

to

use

a

sealing compound, one of the non-

setting type must be used for on future

nccasinns when the head is removed,

the

Loading...

Loading...