ENGINE

cylinder sleeves may

be

disturbed because

of their adherence to the gasket.

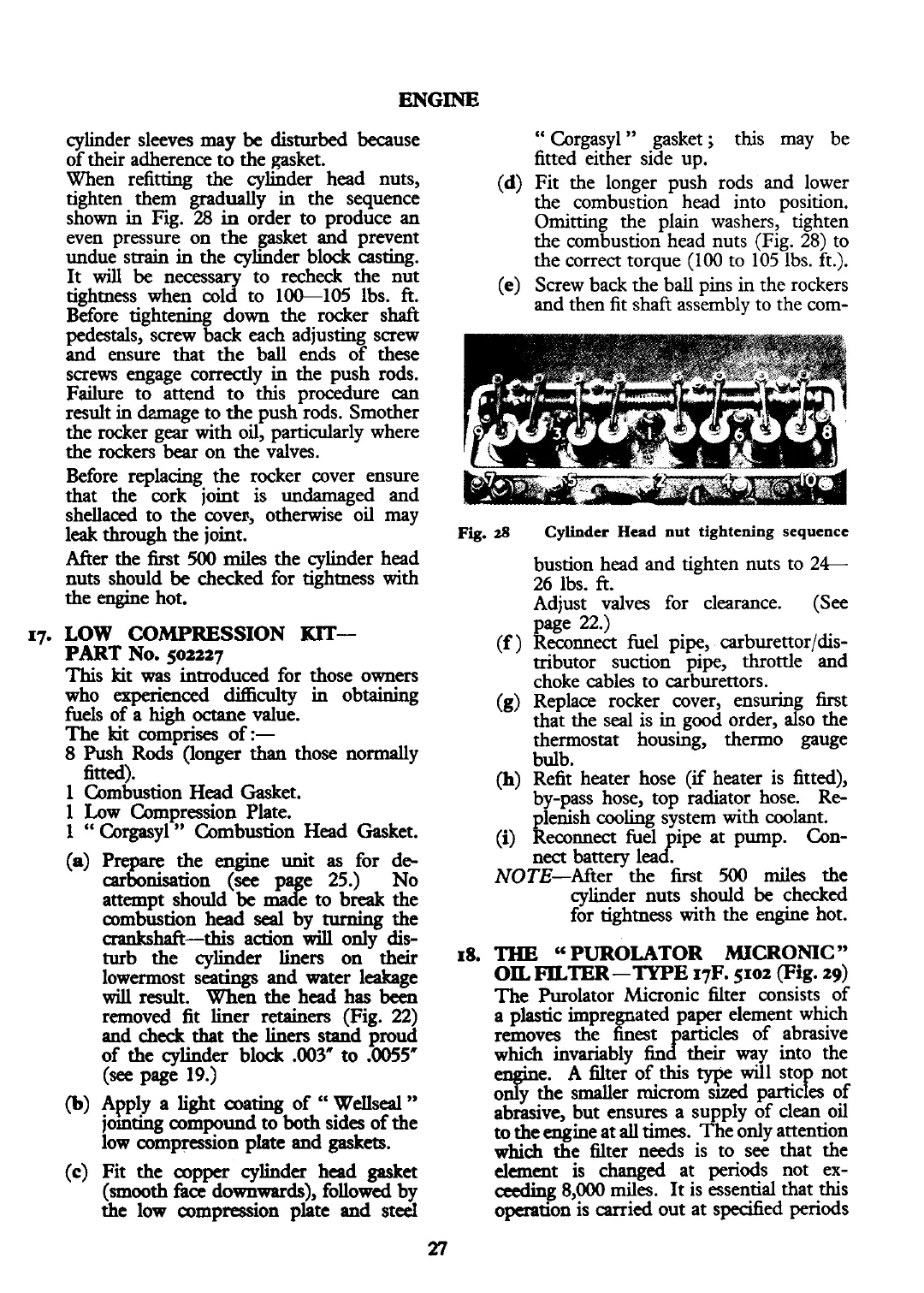

When

refitting the cylinder head nuts,

tighten them gradually in the sequence

shown in

Fig.

28

in

order to produce an

even pressure on the

gasket

and prevent

undue strain in the cylinder block casting.

It

will

be

necessary to recheck the nut

tighmess when cold to 1S105 lbs.

ft.

Before tightening down the rocker shaft

pedestals, screw back each adjusting screw

and ensure that the ball ends of these

screws engage correctly in the push rods.

Failure to attend to this procedure

can

result in dvnage to the push rods. Smother

the rocker gear

with

oil, particularly where

the rockers

bear

on the valves.

Before replacing the rocker cover ensure

that the cork joint is undamaged and

shellaced to the

cover, otherwise oil

may

leak through the joint.

After the first

500

miles the cylinder head

nuts should

be

checked for tighmess with

the engine hot.

17.

LOW

COMPRESSION

KIT-

PART

No.

502227

This kit

was

introduced for those owners

who

experienced

difficulty

in obtaining

fuels of a

high

octane value.

The kit comprises of

:-

8

Push Rods (longer

than

those normally

fitted).

1

Combustion Head Gasket.

1 Low Compression Plate.

1

"

Corgasyl

"

Combustion Head Gasket.

(a)

Pr

are

the engine

unit

as

for de-

car

To

nisation

(see

attempt should

be

ma

?r

e to

25J

break the

combustion head

seal

by

turning

the

crankshaft-this action

will

only dis-

turb the cylinder liners on their

lowennost

seatings

and water leakage

will

result.

When

the head

has

been

removed fit liner retainers (Fig. 22)

and check that the liners stand proud

of the cylinder block

.003"

to

.0055"

(see

Page 19.)

(b)

Apply a light

coating

of

"

Wellseal

"

jomting compound to both sides of the

low compression plate and gaskets.

(C)

Fit the copper cylinder head

gasket

(smooth

face

downwards), followed by

the

low comprrssion plate and steel

"

Corgasyl

"

gasket

;

this may be

fitted either side up.

(d)

Fit the longer push rods and lower

the combustion head into position.

Omitting the plain washers, tighten

the combustion head nuts (Fig. 28) to

the

correct torque (100 to 105 lbs. ft.).

(e)

Screw back the ball pins in the rockers

and then fit shaft assembly to the com-

Fig.

28

Cylinder

Head

nut tightening sequence

bustion head and tighten nuts to 24-

26 lbs.

ft.

Adjust valves for clearance. (See

page 22.)

(f)

Reconnect fuel pipe, carburettor/dis-

tributor suction pipe, throttle and

*A

-

choke cables to carburettors.

(g) Replace rocker cover, ensuring first

that the seal is in good order, also the

thermostat housing, thermo gauge

bulb.

(h)

Refit heater hose

(if

heater is fitted),

by-pass hose, top radiator hose. Re-

plenish cooling system with coolant.

(i)

Reconnect fuel ipe at pump. Con-

nect battery 1eaJ

NOTE-Afier the first

500

miles the

cylinder nuts should

be

checked

for tighmess with the engine hot.

18.

THE

"

PUROLATOR MICRONIC

"

OIL FILTER-TYPE

17F. 5102 (Fig.

29)

The Purolator Micronic filter consists of

a plastic impre ated paper element which

removes

the

Rest fartides of abrasive

which invariably

fin

their way into the

7

e.

A

filter of this

type

will sto

f'

o y the smaller microm swd partic es of

abrasive, but ensures a supply of clean oil

to the engine at

all

times. The only attention

which the filter needs is to see that the

elanent is changed at periods not ex-

&g

8,000

miles. It is essential that this

operation is carried out at specified periods

Loading...

Loading...