ENGINE

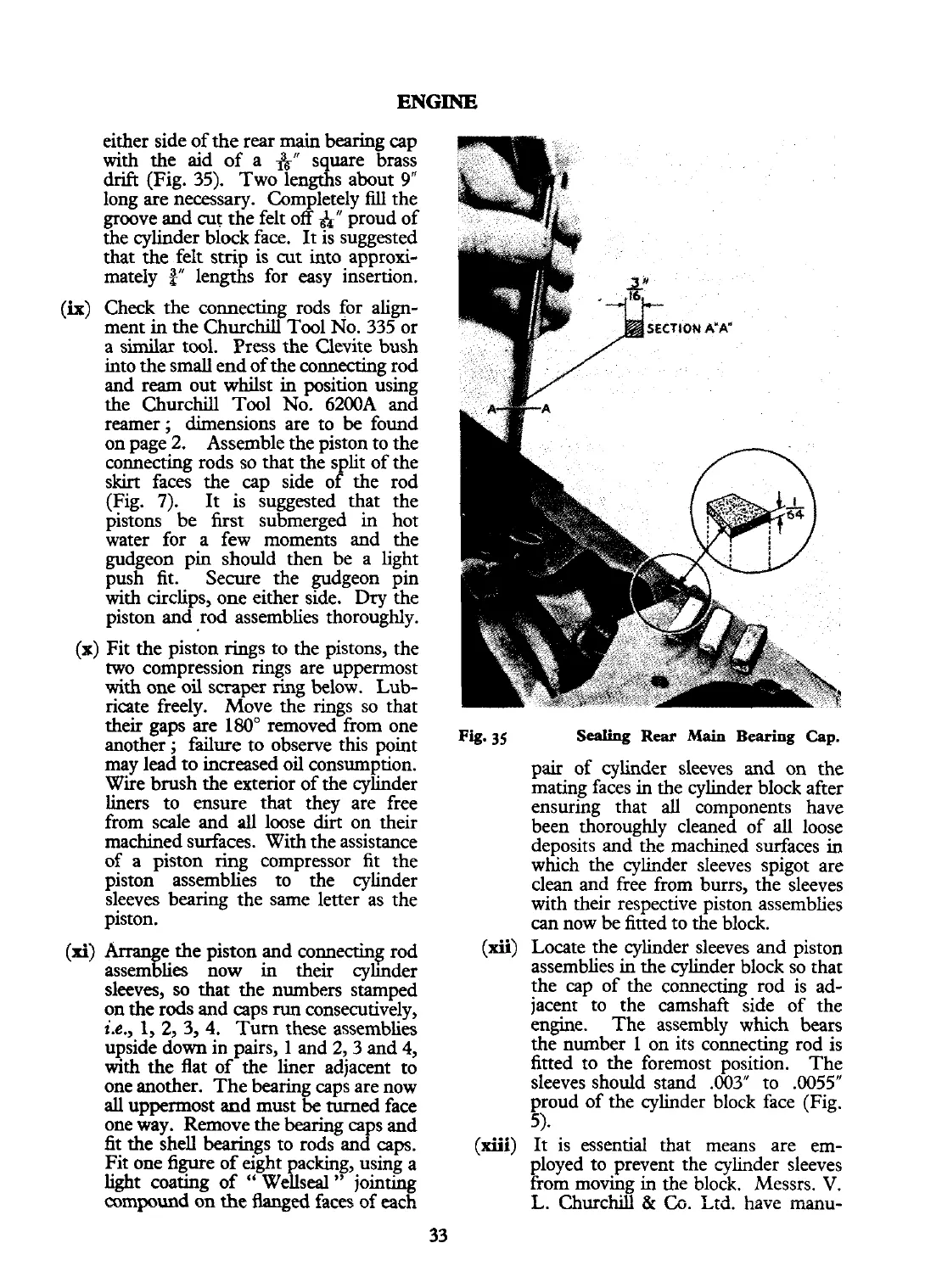

either side of the rear

main

bearing cap

with

the aid of a

A"

square brass

drift (Fig. 35).

Two lengths about

9"

long are necessary. Completely

fill

the

groove and cut the felt off

$4"

proud of

the cylinder block face. It is suggested

that the felt strip is cut into approxi-

mately

a"

lengths for easy insertion.

Check the connecting rods for

align-

ment in the Churchill Tool No. 335 or

a similar tool.

Press the Clevite bush

into the small end of the connecting rod

and ream out whilst in position using

the Churchill Tool No.

6200A and

reamer;

dimensions are to

be

found

on page 2.

Assemble the piston to the

connecting rods so that the split of the

skirt faces the cap side of the rod

(Fig.

7).

It is suggested that the

pistons be first submerged in hot

water for a few moments and the

gudgeon pin should then be a light

push fit.

Secure the gudgeon pin

with circlips, one either side.

Dry

the

piston and rod assemblies thoroughly.

I

Fit the piston rings to the pistons, the

two compression rings are uppermost

with

one oil scraper ring below. Lub-

ricate freelv.

Move the

rings so that

their gaps

ke 180" removed"from one

another

;

failure to observe this point

35

Sealing

Rear

Main

Bearing

Cap.

may lead to increased oil consumption.

pair of cylinder sleeves and on the

Wire brush the exterior of the cylinder

mating faces in the cylinder block after

liners to

ensure that they are free

ensuring that

all

components have

from scale and

all

loose

dirt

on their

been thoroughly cleaned of

all

loose

machined surfaces. With the assistance

deposits and the machined surfaces in

of a piston ring compressor fit the

which the cylinder sleeves spigot are

piston assemblies to the cylinder clean and free from burrs, the sleeves

sleeves bearing the same letter as the with their respective piston assemblies

piston.

can

now be fitted to the block.

e the piston and connecting rod

(4

9

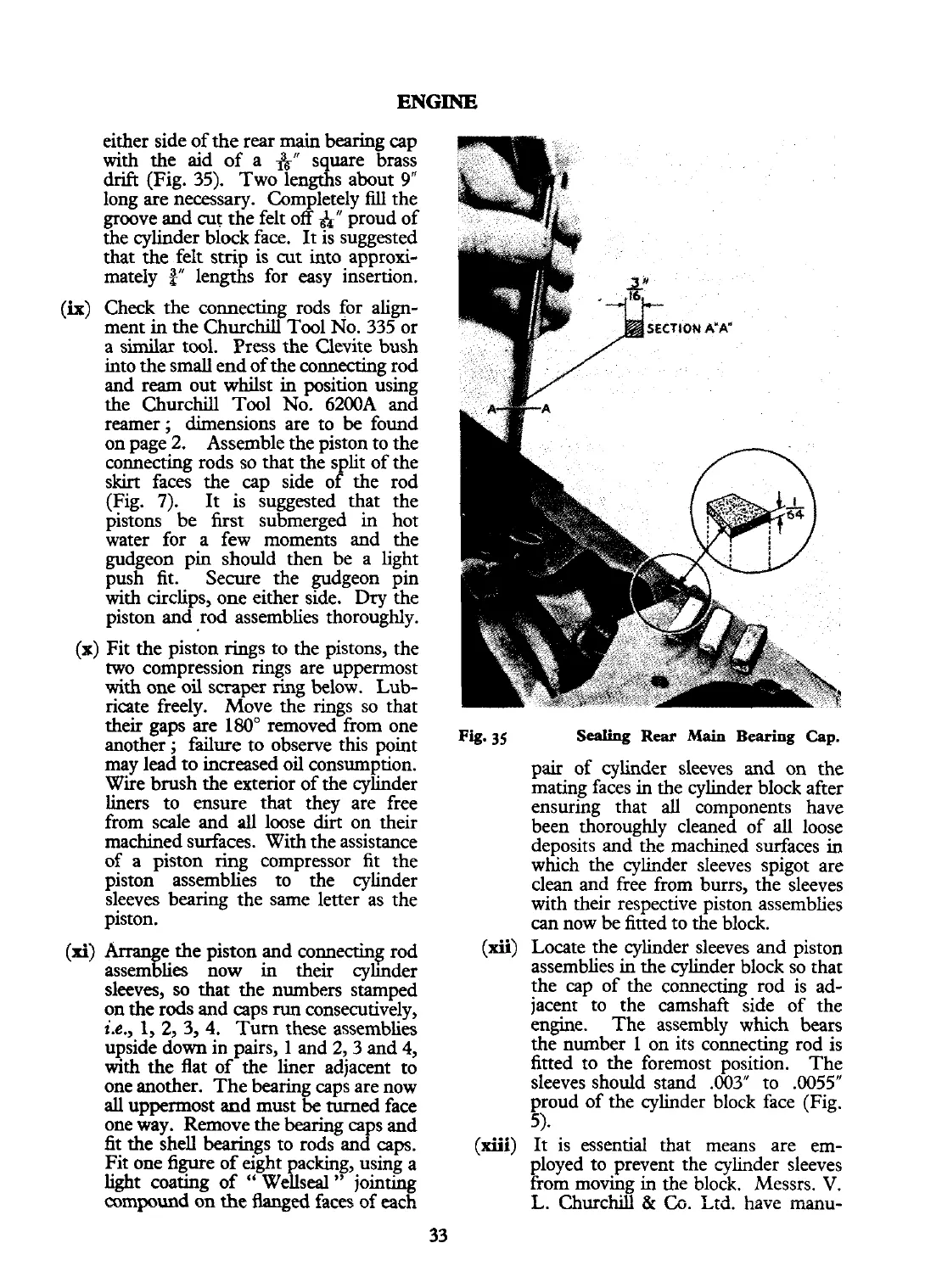

(xii)

Locate the cylinder sleeves and piston

assem lies now in their cyhder assemblies in the cylinder block so that

sleeves, so that the numbers stamped the cap of the connecting rod is

ad-

on the rods and caps

run

consecutively,

jacent to the camshaft side of the

i.e.,

1,

2,

3, 4.

Turn these assemblies engine. The assembly which bears

upside down in pairs, 1 and 2,3 and

4,

the number

1

on its connecting rod is

with

the flat of the liner adjacent to

fitted to the foremost position. The

one another. The bearing caps are now sleeves should stand .003" to .0055"

all

uppermost

and

must

be

turned face proud of the cylinder block face (Fig.

one way. Remove the bearing caps and

5)-

fit the shell bearings to rods and caps.

(xiii)

It is essential that means are em-

Fit one figure

of

eight packing, using a ployed to prevent the cylinder sleeves

light coating of

"

Wellseal

"

jointmg

from moving in the block. Messrs.

V.

compound on

the

Aanged faces ~f each L. Churchill

&

Co.

Ltd. have inanu-

33

Loading...

Loading...