Fit the bearing cap and tighten

down

suf5ciently to nip the mandrel.

Tighten

the

eight bolts to secure the

oil seal to the cylinder block and

bear-

ingcap (torqueloadingof

8-10

lbs.

ft).

Remove bearing cap fiom block.

(ii)

Fit the upper half of the

main

bearings

to the cylinder block; thoroughly clean

and lubricate

;

place the crankshaft

in

position.

(iii)

Fit the lower halves of the

main

.

.

bearings to the bearing caps,

and

lubricate.

(iv)

Thread the two top halves of the thrust

washers at the side of the centre main

bearing between the crankshaft and the

cylinder block.

It is essential that the white metal

side is toward the crankshaft.

Fit the thrust washers, one either side,

to the centre bearing cap (Fig.

34)

and

lightly secure with the two bolts and

lock washers to cylinder block. Fit the

two remaining caps to the cylinder

block

with

two bolts and two lock

washers each.

(v)

Commencing from the front of the

engine, tighten the bearings cap bolts

to the correct torque (see "General

Data").

On

tightening the rear bearing

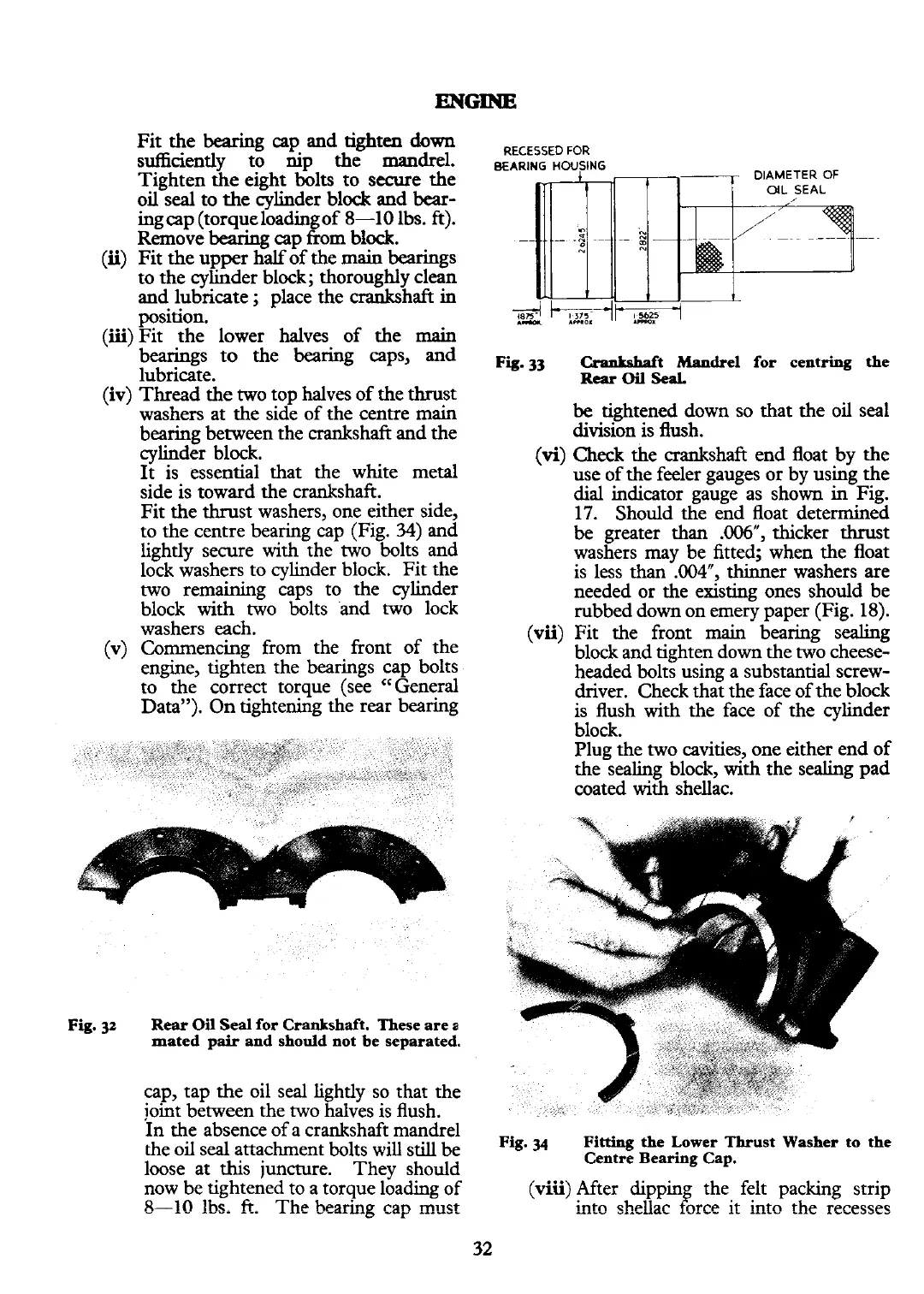

RECESSED FOR

BEARING

HOUSING

-,-

DIAMETER

OF

Fig.

33

Crankshaft

Mandrel for centring the

Rear

Oil

SePL

be

tightened down so that the oil seal

division is flush.

(vi)

Check

the crankshaft end float by the

use of the feeler gauges or by using the

dial indicator gauge as shown

in

Fig.

17.

Should the end float determined

be greater than

.006",

thicker thrust

washers may be fitted; when the float

is less than

.004,

thinner washers are

needed or the existing ones should be

rubbed down on emery paper (Fig. 18).

(vii) Fit the front

main

bearing sealing

block and tighten down the two cheese-

headed bolts using a substantial screw-

driver. Check that the face of the block

is flush with the face of the cylinder

block.

Plug the two cavities, one either end of

the sealing block, with the sealing pad

coated

with

shellac.

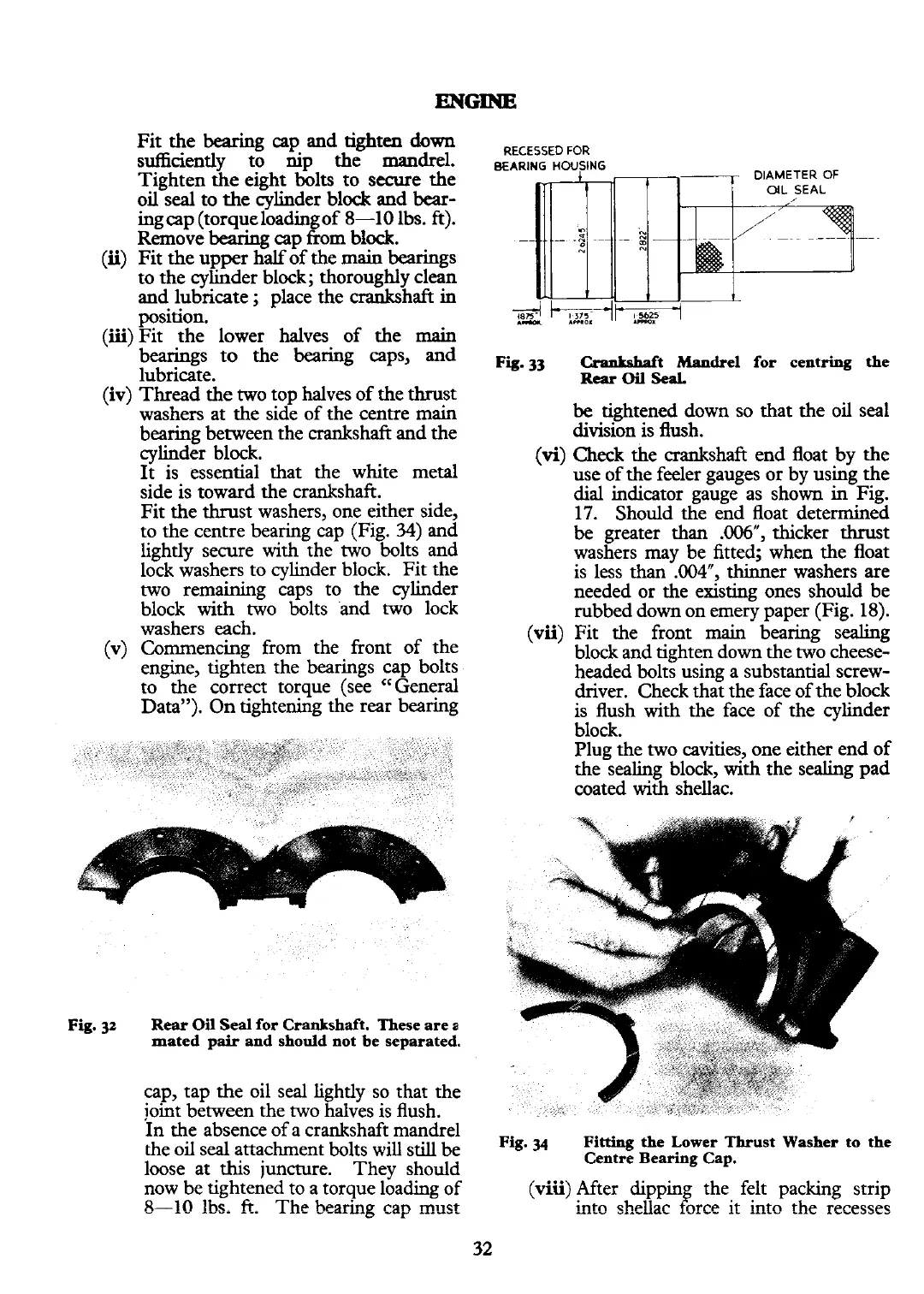

Fig.

32

Rear

Oil

Seal for Crankshaft. These are

a

mated pair and should not be separated.

cap, tap the oil seal lightly so that the

ioint between the two halves is flush.

In the absence of a crankshaft mandrel

he

oil

seal

bolts still be

Fig.

M

Fitting

the Lower Thrust Washer to the

Centre Bearing Cap.

loose at this iuncture. Thev should

now be tightened to

a

torque 16ading of

(viii) After dippin

the felt packing strip

8-10

lbs-

fti

The hearing cap must

into shellac &re it into the recesses

Loading...

Loading...