COOLING

solder

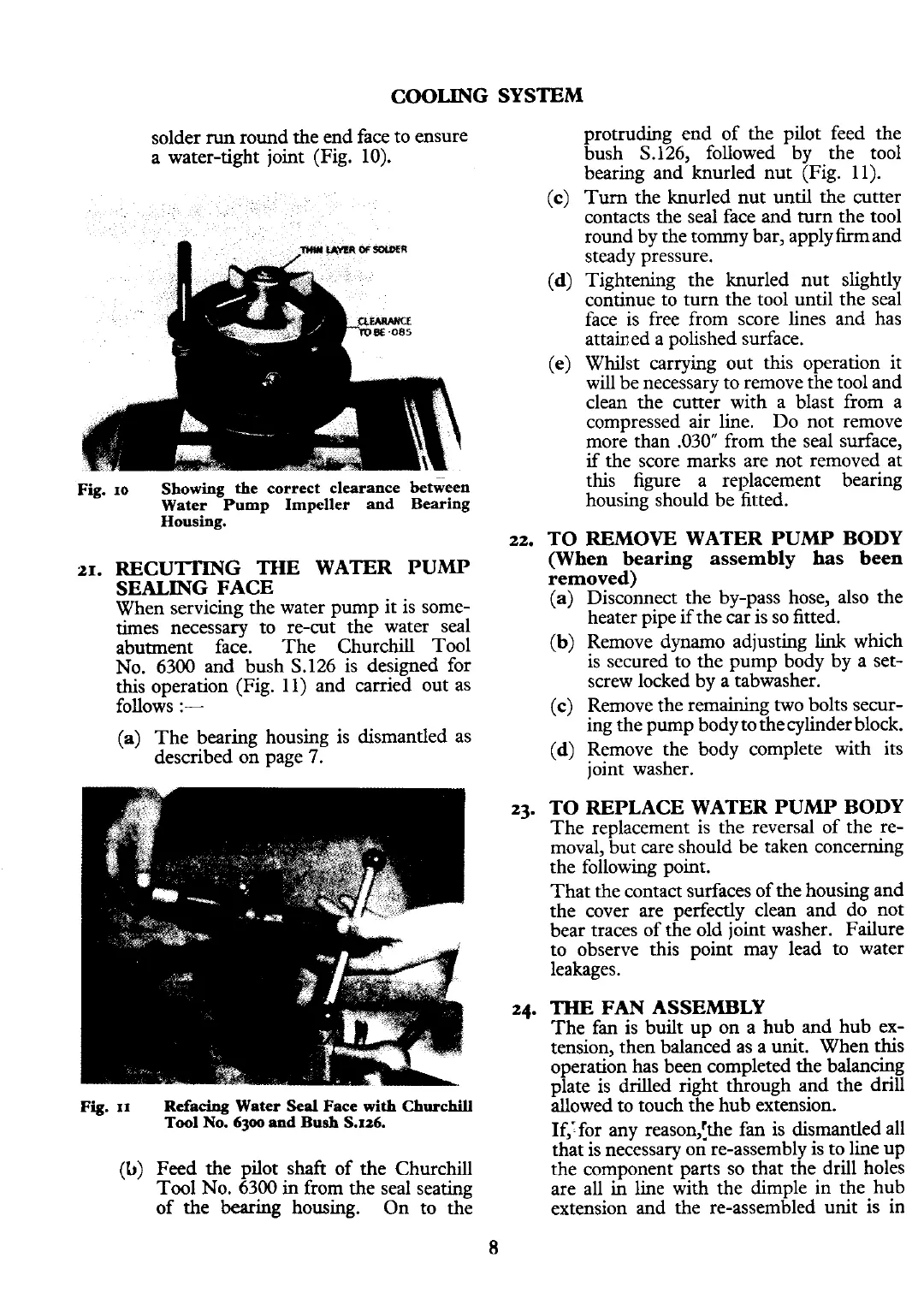

run

round the end face to ensure

a water-tight joint (Fig. 10).

Fig.

21.

10

Showing the correct clearance between

Water Pump Impeller and Bearing

Housing.

RECUTlWG THE WATER PUhW

SEALING FACE

When servicing the water pump it is some-

times

necessary to re-cut the water seal

abutment face. The Churchill Tool

No.

6300

and bush S.126 is designed for

this operation (Fig. 11) and carried out as

follows

:-

(a)

The bearing housing is dismantled as

described on page

7.

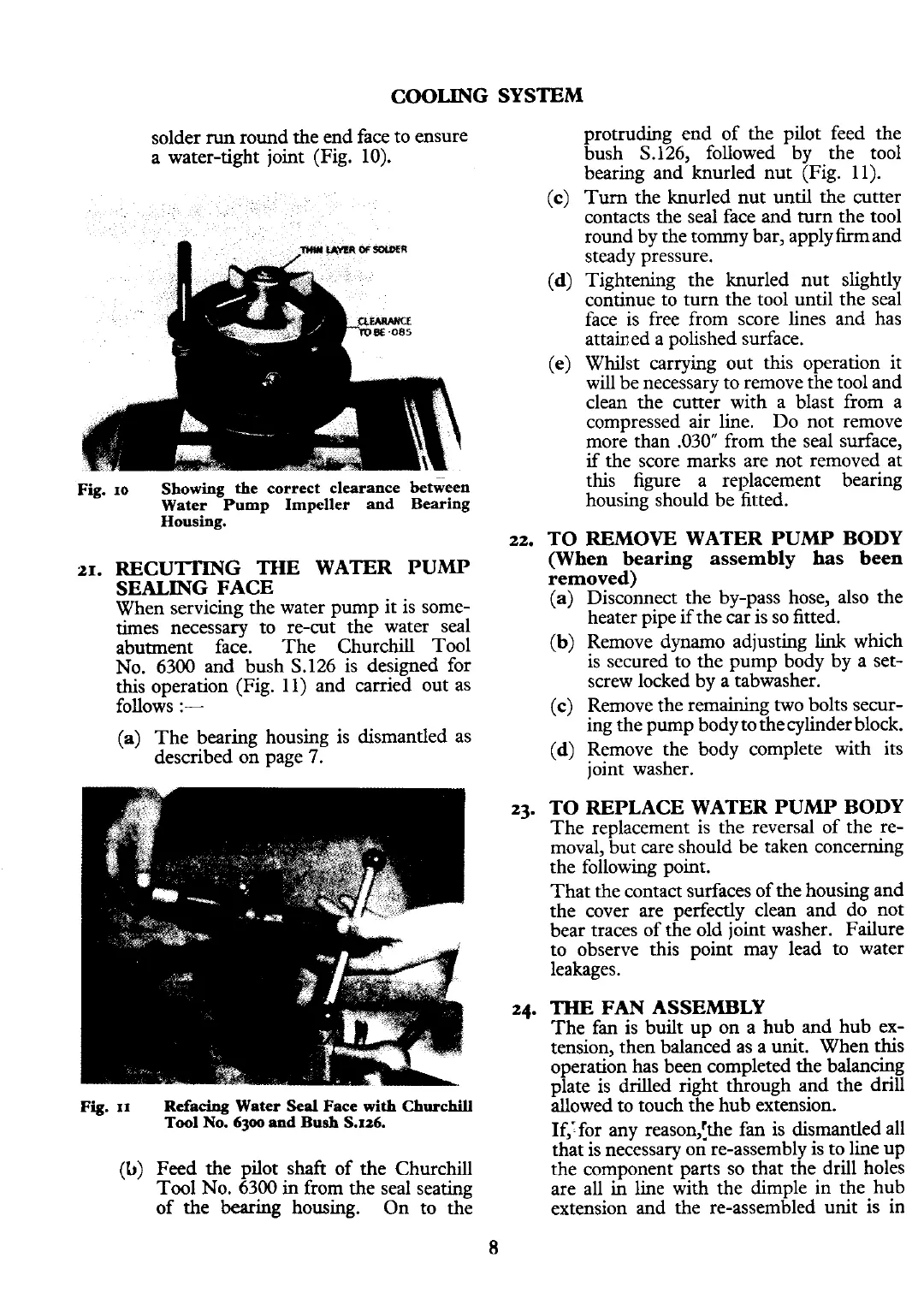

Fig.

11

Refacing Water

Seal

Face

with

Churchill

Tool

No.

6300

and Bush

S.126.

Feed the pilot shaft of the Churchill

Tool No.

6300

in from the seal seating

of the bearing housing. On to the

SYSTEM

protruding end of the pilot feed the

bush S.126, followed by the tool

bearing and knurled nut (Fig. 11).

Turn the knurled nut until the cutter

contacts the seal face and turn the tool

round by the

tornmy bar, applyfirmand

steady pressure.

Tightening the knurled nut slightly

continue to turn the tool until the seal

face is free from score lines and has

attained a polished surface.

Whilst carrying out this operation it

will be necessary to remove the tool and

clean the cutter with a blast from a

compressed air line. Do not remove

more than

.030" from the seal surface,

if

the score marks are not removed at

this figure a replacement bearing

housing should be fitted.

TO

REMOVE

WATER PUlMP BODY

(When bearing assembly

has

been

removed)

(a) Disconnect the by-pass hose, also the

heater pipe

if

the car is so fitted.

(b) Remove dynamo adjusting

link

which

is secured to the pump body by a set-

screw locked by a tabwasher.

(c)

Remove the remaining two bolts secur-

ing the pump body tothe cylinder block.

(d) Remove the body complete with its

joint washer.

TO REPLACE WATER PUMP BODY

The replacement is the reversal of the re-

moval, but care should be taken concerning

the following point.

That the contact surfaces of the housing and

the cover are perfectly clean and do not

bear traces of the old joint washer. Failure

to observe this point may lead to water

leakages.

THE

FAN

ASSEMBLY

The fan is built up on a hub and hub ex-

tension, then balanced as a unit. When this

operation has been completed the balancing

plate is drilled right through and the drill

allowed to touch the hub extension.

If,:for any reasonlthe fan is dismantled all

that is necessary on re-assembly is to line up

the component parts so that the drill holes

are all in line with the dimple in the hub

extension and the re-assembled unit is in

Loading...

Loading...