COOLING

SYSTEM

It

will

be

noted that the bolt

is

tra

ped

B

(c)

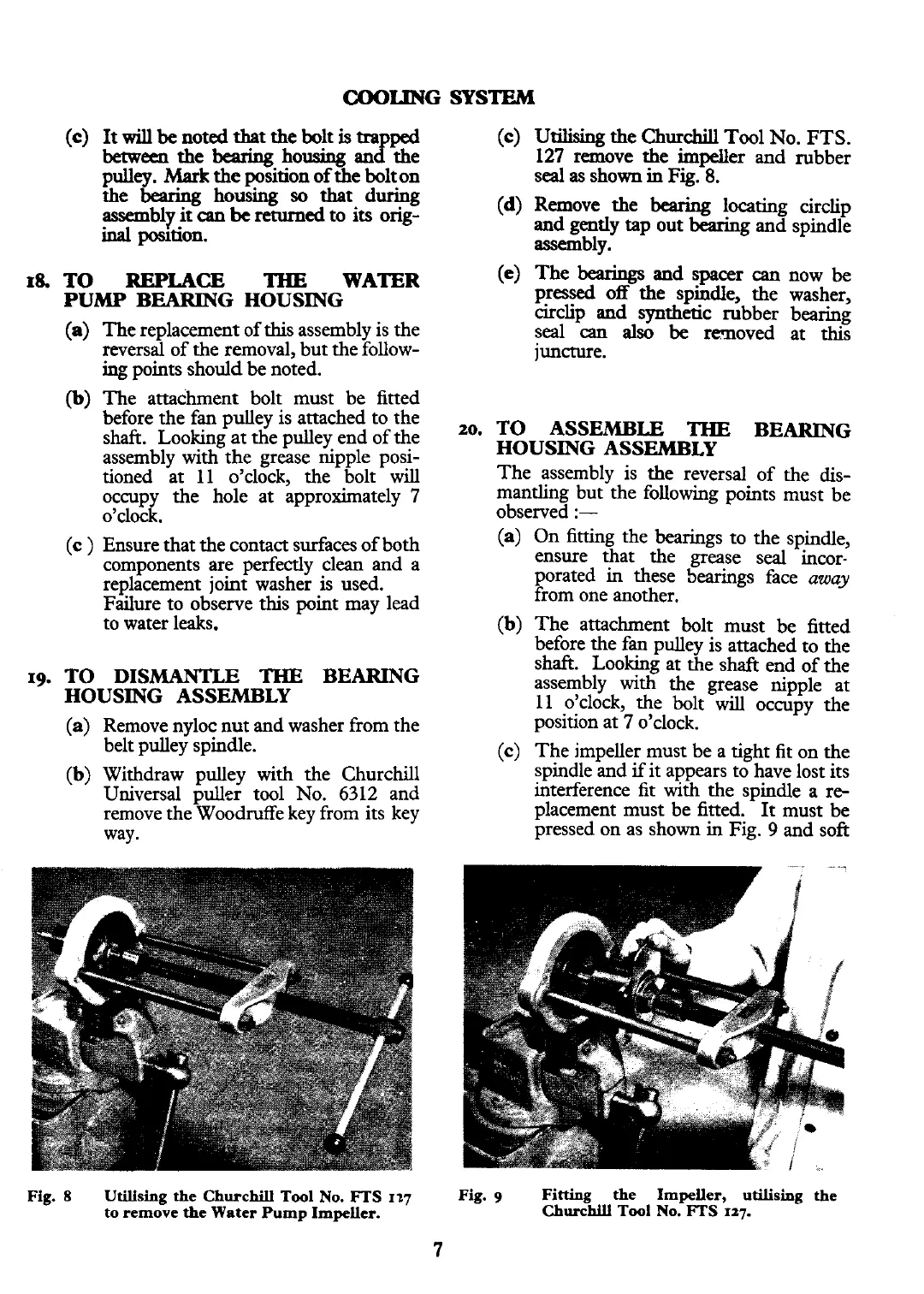

Utilising

the

Churchill

Tool No.

FTS.

between

the

bearing

housing an the

127

remove the impeller and rubber

pulley.

Mark

the position of the bolt on

seal

as

shown

in

Fig.

8.

the

bearing

housing

so

that

during

assembly

it

can

be

retumed to its orig-

(d)

Remove the

bearing

locating circlip

inal

poution.

and gently

tap

out

bearing

and spindle

assembly.

18.

TO

REPLACE

THE

WATER

(e)

The

bearings

and spacer

can

now

be

PUW BEARING HOUSING

pressed off the spindle, the washer,

circlip and synthetic rubber bearing

The replacement of this assembly is the

reversal of the removal, but the follow-

ing

points should be noted.

The attachment bolt must be fitted

before the fan pulley is attached to the

shaft. Looking at the pulley end of the

assembly with the grease nipple posi-

tioned at

11 o'clock, the bolt will

occupy the hole at approximately

7

o'clock.

Ensure that the contact surfaces of both

components are perfectly clean and a

replacement joint washer is used.

Failure to observe this point may lead

to water leaks.

19.

TO DISMANTLE

THE

BEARING

HOUSING ASSEMBLY

(a)

Remove nyloc nut and washer from the

belt pulley spindle.

(b)

Withdraw pulley with the Churchill

Universal puller tool No. 6312 and

remove the Woodruffe key from its key

way.

seal

-can

als6

be

removed at

thii

juncture.

20.

TO ASSEMBLE

THE

BEARING

HOUSING ASSEMBLY

The assembly is the reversal of the dis-

mantling but the following points must be

observed

:-

(a)

On fitting the bearings to the spindle,

ensure that the grease seal incor-

porated in these bearings face

away

from one another.

(b)

The attachment bolt must be fitted

before the fan pulley is attached to the

shaft.

Looking

at the shaft end of the

assembly with the grease nipple at

11 o'clock, the bolt will occupy the

position at

7

o'clock.

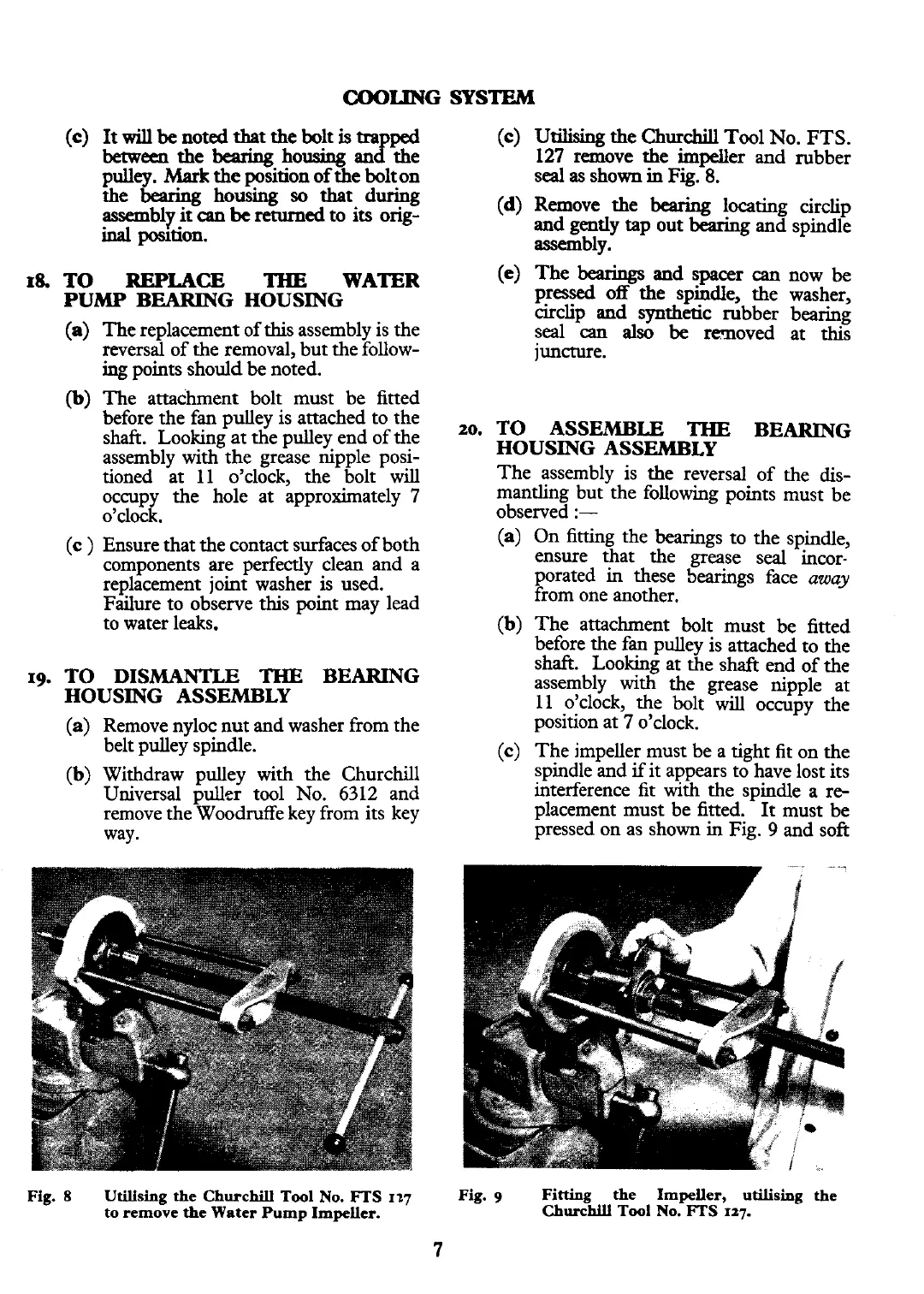

(c)

The impeller must be a tight fit on the

spindle and

if

it appears to have lost its

interference

fit

with the spindle a re-

placement must be fitted. It must be

pressed on as shown in Fig.

9

and soft

Fig.

8

Utilising

the

Churchill

Tool

No.

FTS

127

to

remove

the

Water

Pump

Impeller.

Fig.

9

Fitting

the

Impeller,

utilising

the

Ch~r~hill

Tool

NO.

mS

127.

7

Loading...

Loading...