General information VFL

Application

– Circular volume flow limiters of Type VFL

for the simple balancing of volume flow rates

in air conditioning systems

– Mechanical self-powered volume flow limiter

without external power supply

– Simplified project handling with orders based

on nominal size

– Set the required volume flow rate using a scale

Nominal sizes

– 4", 5", 6", 8", 10"

Special features

– Mechanical self-powered

– Low-friction bellows

– For circular ducts

– Lip seal for tight and secure fit

– Aerodynamically tested and factory set

to a reference volume flow rate

– Sticker showing volume flow rates (in l/s, m³/h

and cfm) that can be set for each limiter

Parts and characteristics

– Ready-to-commission limiter

– Damper blade with low-friction bearings

– Bellows that acts as an oscillation damper

– Leaf spring

– Lip seal

– Multi-level volume flow rate setpoint values

Construction features

– Circular casing

– Lip seal for tight and secure fit

– Acoustically optimized damper blade with

low- friction bearings and special bellows

– Different damper blade construction and

volume flow rate sticker for nominal size 150

Materials and surfaces

– Casing and damper blade made of

high-quality plastic, to UL 94, V1;

to DIN 4102, material classification B2

– Leaf spring made of stainless steel

– Polyurethane bellows

Installation and commissioning

– Any installation orientation

– Set the required volume flow rate using a scale

– Insert the unit into the duct

– Mark the installation location

Standards and guidelines

– Hygiene conforms to VDI 6022

Maintenance

– Maintenance-free as construction

and materials are not subject to wear

Description

Volume flow limiter

Type VFL

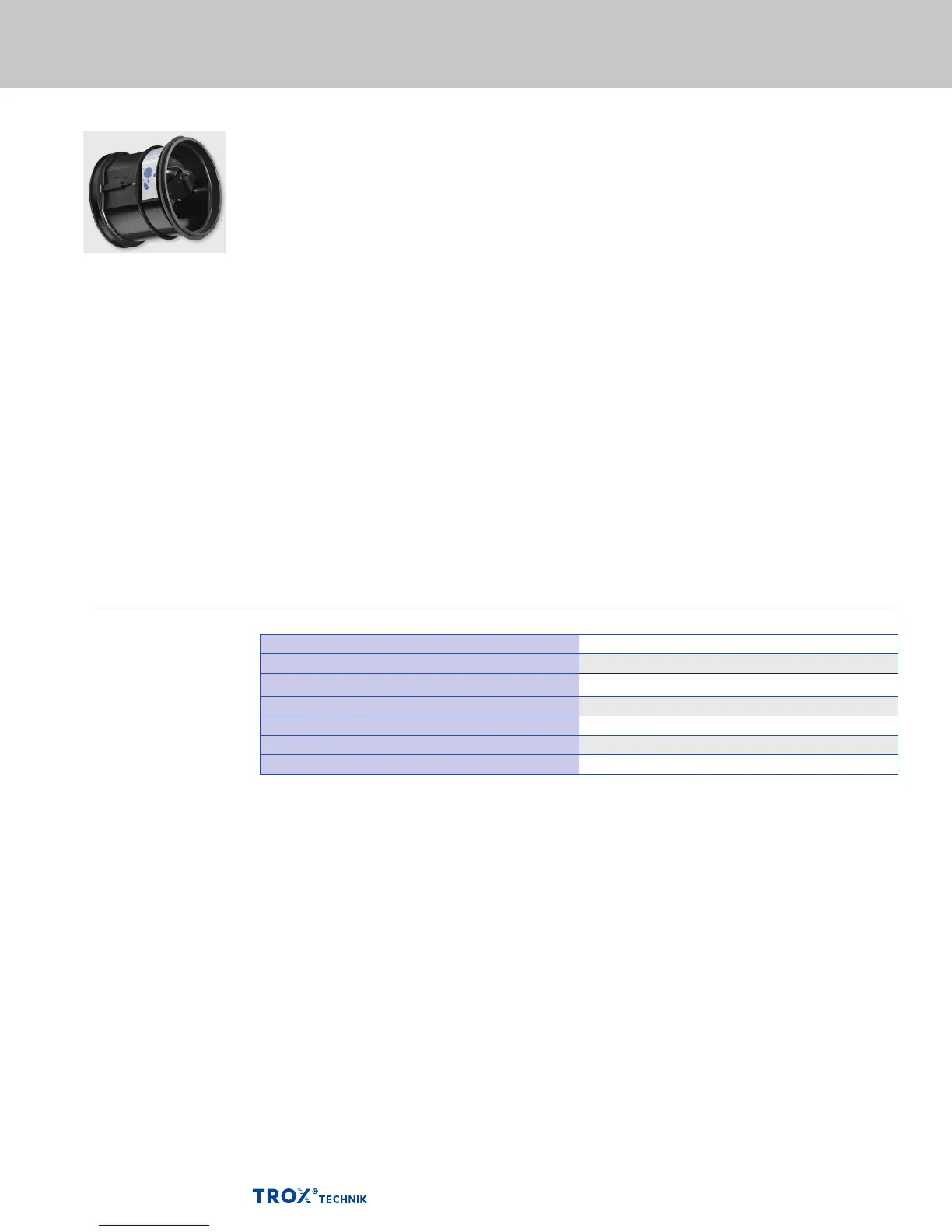

Technical data

Nominal sizes 4 - 10 inches

Volume flow rate range 11 - 450 CFM

Volume flow rate setting range <20 - 100% of the nominal volume flow rate

Volume flow rate accuracy approx. ± 10 % of the nominal volume flow rate

Minimum differential pressure 0.12 in w.g.

Maximum acceptable differential pressure 1.2 in w.g.

Operating temperature 50 – 120 °F

04/2014 US K5 – 2.1 – 3

–

Loading...

Loading...