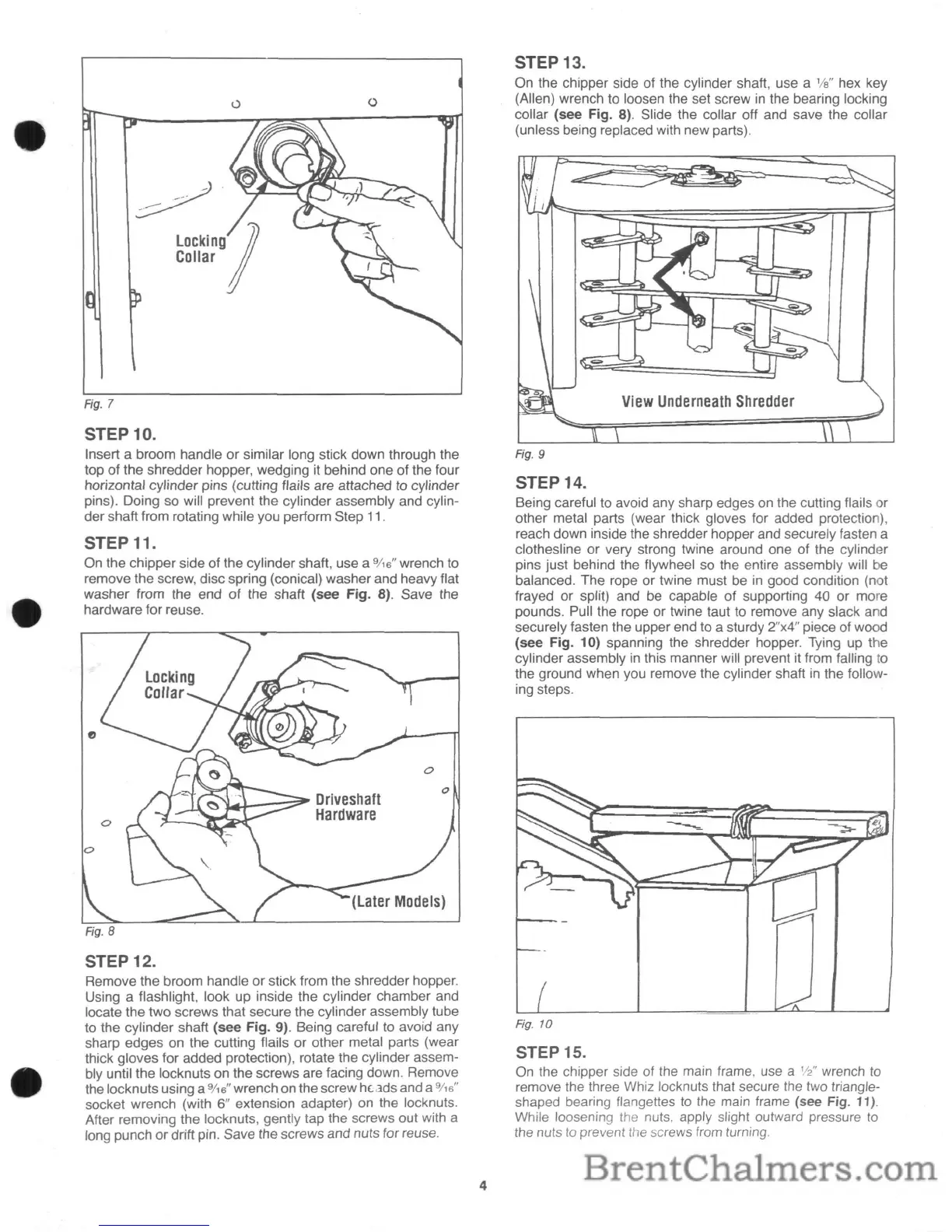

View

Underneath

Shredder

Fig.

9

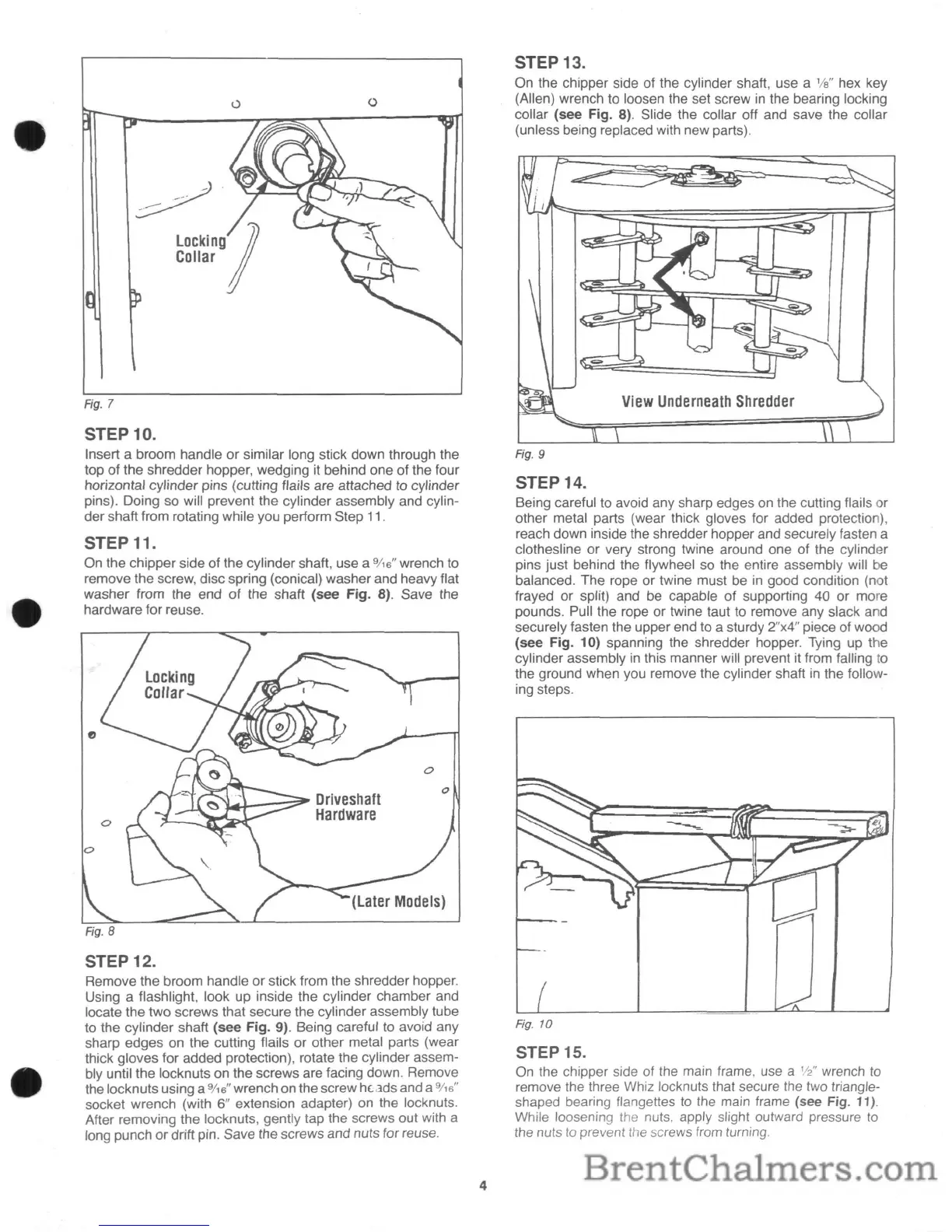

Fig.

10

STEP 14.

Being careful to avoid any sharp edges on the cutting flails or

other metal parts (wear thick gloves for added protection),

reach down inside the shredder hopper and securely fasten a

clothesline or very strong twine around one of the cylinder

pins just behind the flywheel so the entire assembly will be

balanced. The rope or twine must

be

in

good condition (not

frayed or split) and

be

capable of supporting 40 or more

pounds. Pull the rope or twine taut to remove any slack and

securely fasten the upper end to a sturdy 2"x4" piece of wood

(see Fig. 10) spanning the shredder hopper. Tying up the

cylinder assembly

in

this manner will prevent

it

from falling

to

the ground when you remove the cylinder shaft

in

the follow-

ing steps.

STEP 13.

On

the chipper side of the cylinder shaft, use a

1fa"

hex key

(Allen) wrench to loosen the set screw

in

the bearing locking

collar

(see Fig.

8).

Slide the collar off and save the collar

(unless being replaced with new parts).

STEP 15.

On

the chipper side of the main frame, use a

'/2"

wrench

to

remove the three Whiz locknuts that secure the two triangle-

shaped bearing

f1angettes

to

the main frame (see Fig.

11).

While loosening the nuts. apply slight outward pressure

to

the nuts

to

prevent the screws

from

turning.

o

STEP 12.

Remove the broom handle or stick from the shredder hopper.

Using a flashlight, look up inside the cylinder chamber and

locate the two screws that secure the cylinder assembly tube

to

the cylinder shaft (see Fig. 9). Being careful to avoid any

sharp edges on the cutting flails or other metal parts (wear

thick gloves for added protection), rotate the cylinder assem-

bly until the locknuts on the screws are facing down. Remove

the locknuts using a

9/

16

" wrench on the screw h('3ds and a

9/

16

"

socket wrench (with 6" extension adapter) on the locknuts.

After removing the locknuts, gently tap the screws out with a

long punch or driftpin. Save the screws and nuts for reuse.

-_.~

~

LOCking/

Y

Collar

!

STEP 10.

Insert a broom handle or similar long stick down through the

top of the shredder hopper, wedging it behind one of the four

horizontal cylinder pins (cutting

flails are attached

to

cylinder

pins). Doing so will prevent the cylinder assembly and cylin-

der shaft from rotating while you perform Step 11.

Fig.

7

STEP 11.

On the chipper side of the cylinder shaft, use a

9/

16

" wrench to

remove the screw, disc spring (conical) washer and heavy flat

washer from the end

of

the shaft (see Fig. 8). Save the

hardware for reuse.

4

Loading...

Loading...