Clean Boiler

• Removeboilerbygraspinghandleandpullingitoutofchassis(g.C).

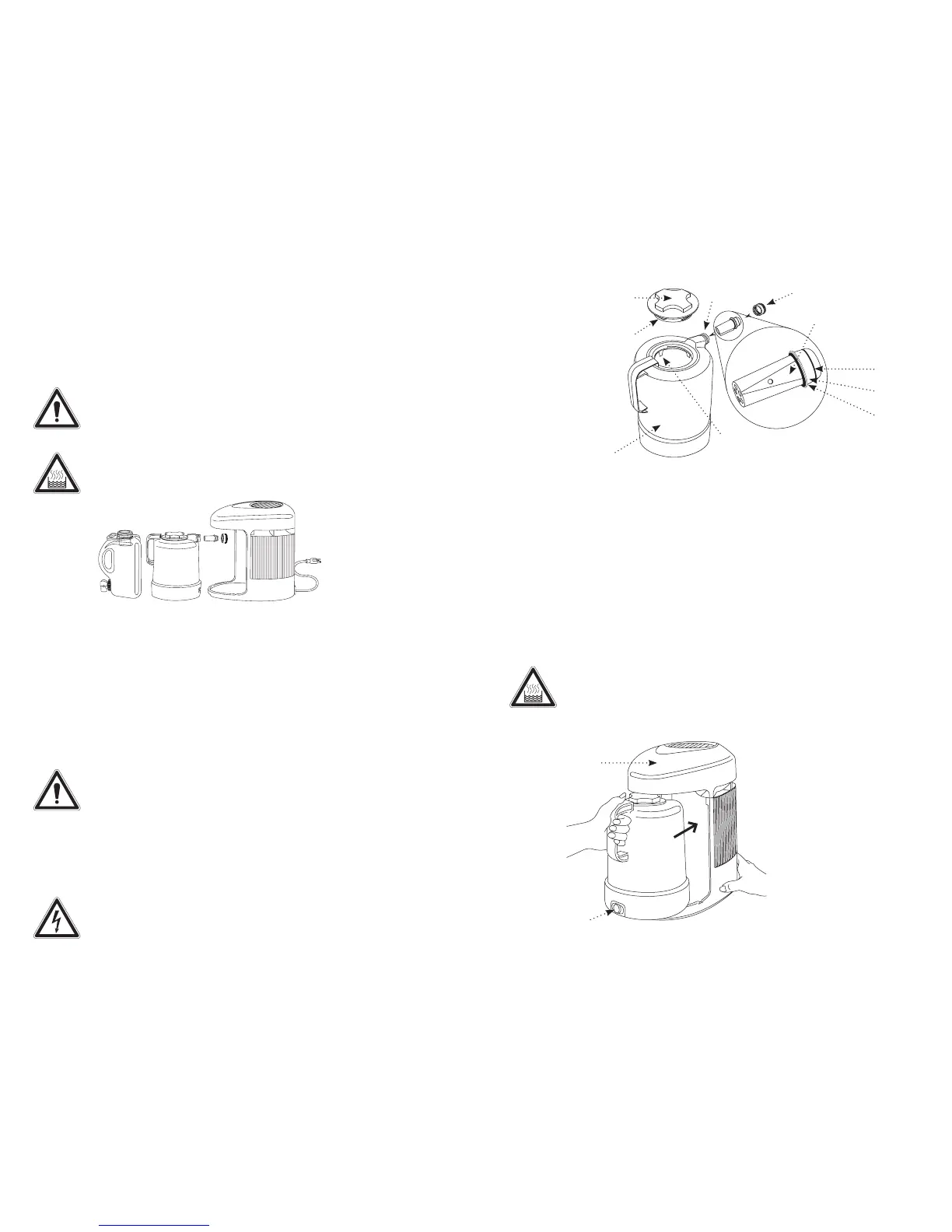

• Removeboilercapbyturningitcounterclockwise(g.D).

• Loosensteambafesecuringnutbyturningcounterclockwiseand

remove steam baffle (fig. D).

• Washinsideofboilerwithsoapandwater.

• Rinsethoroughly.Watershouldbedrainedthroughboilerspout.

IMPORTANT: Wipe off all water deposits inside the Distiller chassis and

on the outside of the boiler before each distillation cycle.

USING THE COUNTERTOP DISTILLER

WARNING: Never remove the boiler while the fan motor is running, or

for 30 minutes after it stops. Severe burns can result from boiling water or

steam. DO NOT change position or location of distiller while it is operating

or cooling.

Operational

maintenance

and replacement

requirements are

essential for this

product to

perform as

advertised.

1. Set Distiller on dry, level, well-supported, stable surface.

2. Remove collector/dispenser bottle.

3. Remove boiler by grasping its handle and pulling it out of chassis.

4. Remove boiler cap by turning it counterclockwise (fig. D).

5. Loosen steam baffle securing nut by turning counterclockwise and

remove steam baffle (fig. D).

6. Rinse boiler thoroughly before filling. The water should be drained

through boiler spout.

7. Fill boiler with ordinary tap water to bottom of four tabs in boiler

opening, approximately 1 gallon (3.8 Liters). These tabs indicate the

MAXIMUM FILL POINT. DO NOT OVERFILL (fig. D).

8. Replace boiler cap by turning it clockwise until tight.

9. Make sure gasket is installed on long end of steam baffle and that it

is snug against flange (fig D). Insert long end of baffle, flat side

down, into the boiler spout. Turn securing nut clockwise onto spout

until tight, being careful to not cross thread.

IMPORTANT: Wipe off all water deposits inside the Distiller chassis and

on the outside of the boiler before each distillation cycle.

6

Figure C

Figure D

7

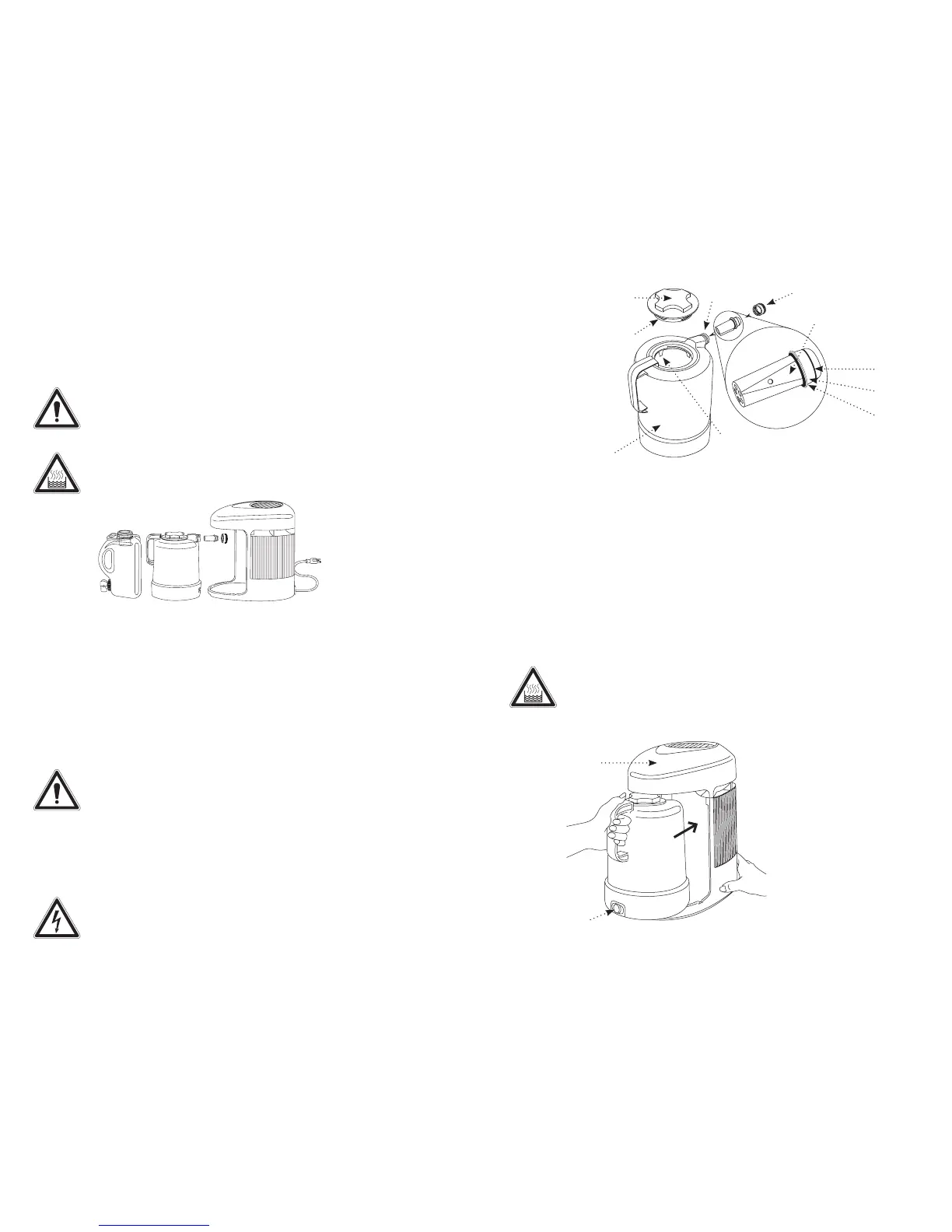

10. Slide boiler into chassis compartment and press firmly to ensure boiler

is properly placed (fig. E). To prevent personal injury or property

damage, the boiler must be fully engaged prior to start-up.

11. Plug power cord into a properly rated, grounded outlet.

12. Press “Start” button at base of boiler (fig. E). “Start” button will illum-

inate when heating; however, the light will go out and boiler will stop

heating if electrical power is interrupted or stopped. If this occurs,

press “Start” button again to restart the distillation cycle.

NOTE: The cooling fan will not start immediately because of a

delayed fan start-up feature. The fan will start once the boiler has

reached a predetermined temperature, approximately 30 to 40 minutes

after starting the cycle.

WARNING: To prevent personal injury, burn and/or scald injury,

DO NOT remove boiler while “Start” button is illuminated or at any time

when the boiler is hot. Always unplug Distiller from wall outlet and allow

boiler to cool completely before removing it from the Distiller (at least 30

minutes). DO NOT change

position or location of Dis-

tiller while it is operating or

cooling.

13. Place prepared carbon

filter cup into opening

at the top of the collec-

tor/dispenser bottle.

DO NOT install cap

onto bottle (fig. F).

14. Replace the collector/

dispenser bottle

(fig. F). Make sure the

dispensing valve is

securely tightened.

Distiller ChassisBoilerCollector/

Dispenser

Bottle

Gasket

Spout

Steam Baffle (flat side)

Boiler

Maximum Fill Point

(bottom of tabs)

Flange

O-ring

Steam Baffle Securing Nut

Boiler Cap

Gasket

Boiler Cap

Distiller

Chassis

Start

Button

Boiler

Loading...

Loading...