ISC and VOC marked on the Module should be multiplied by a factor of 1.25 when to

determining component voltage ratings, current ratings, fuse sizes, and size of controls

connected to the PV output.

Completely cover the Modules with an opaque material to prevent electricity from being

generated during disassembling the conductors.

It is not allowed to use the Modules in different models in the same solar photovoltaic

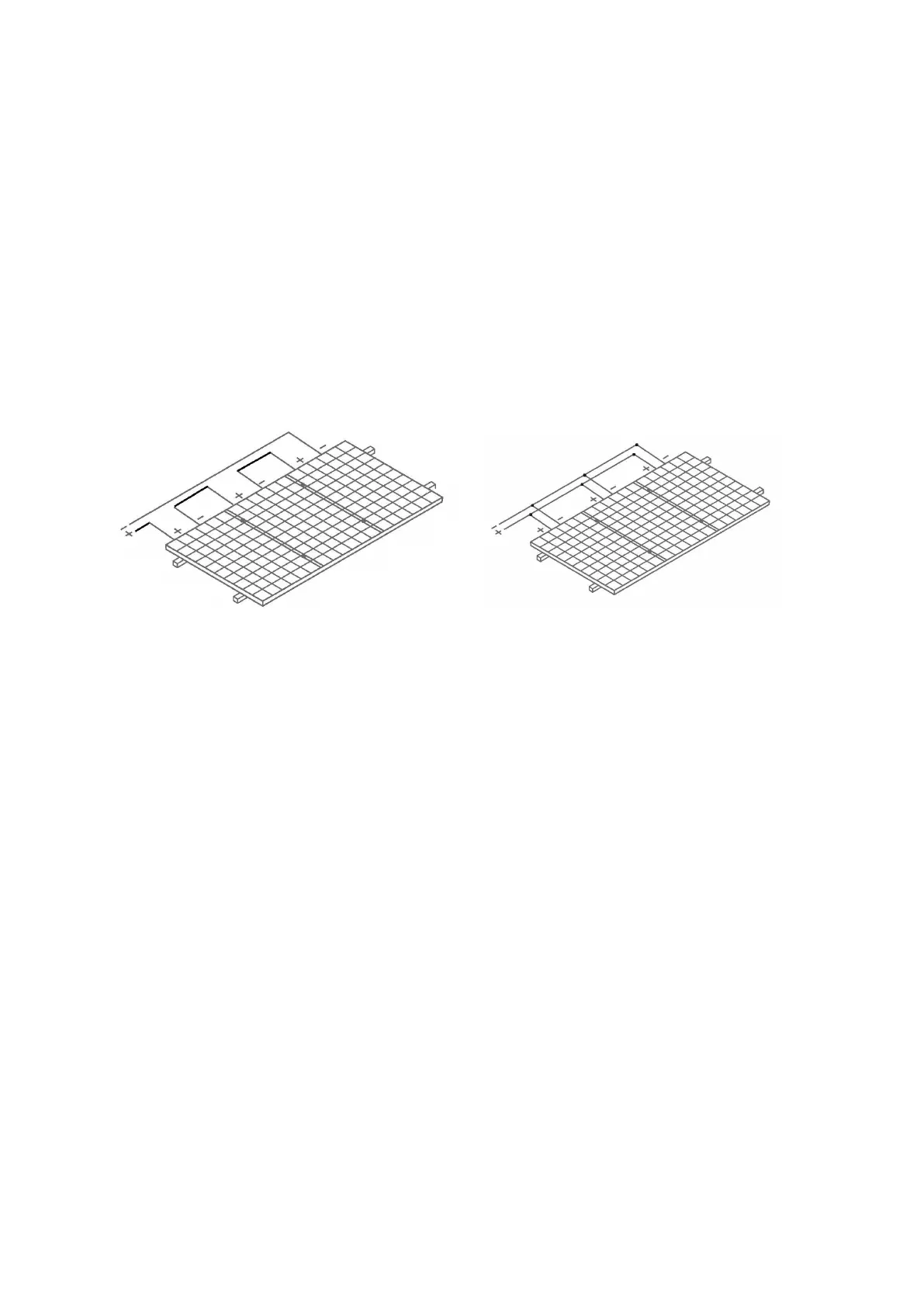

system. When the Modules are connected in series, the voltage of every string shall not be

higher than the maximum voltage of the system (as shown in Figure 5). Reference equation

of the maximum number of the Modules in serial connection: maximum system voltage of

the module/ (1.25* open-circuit voltage).

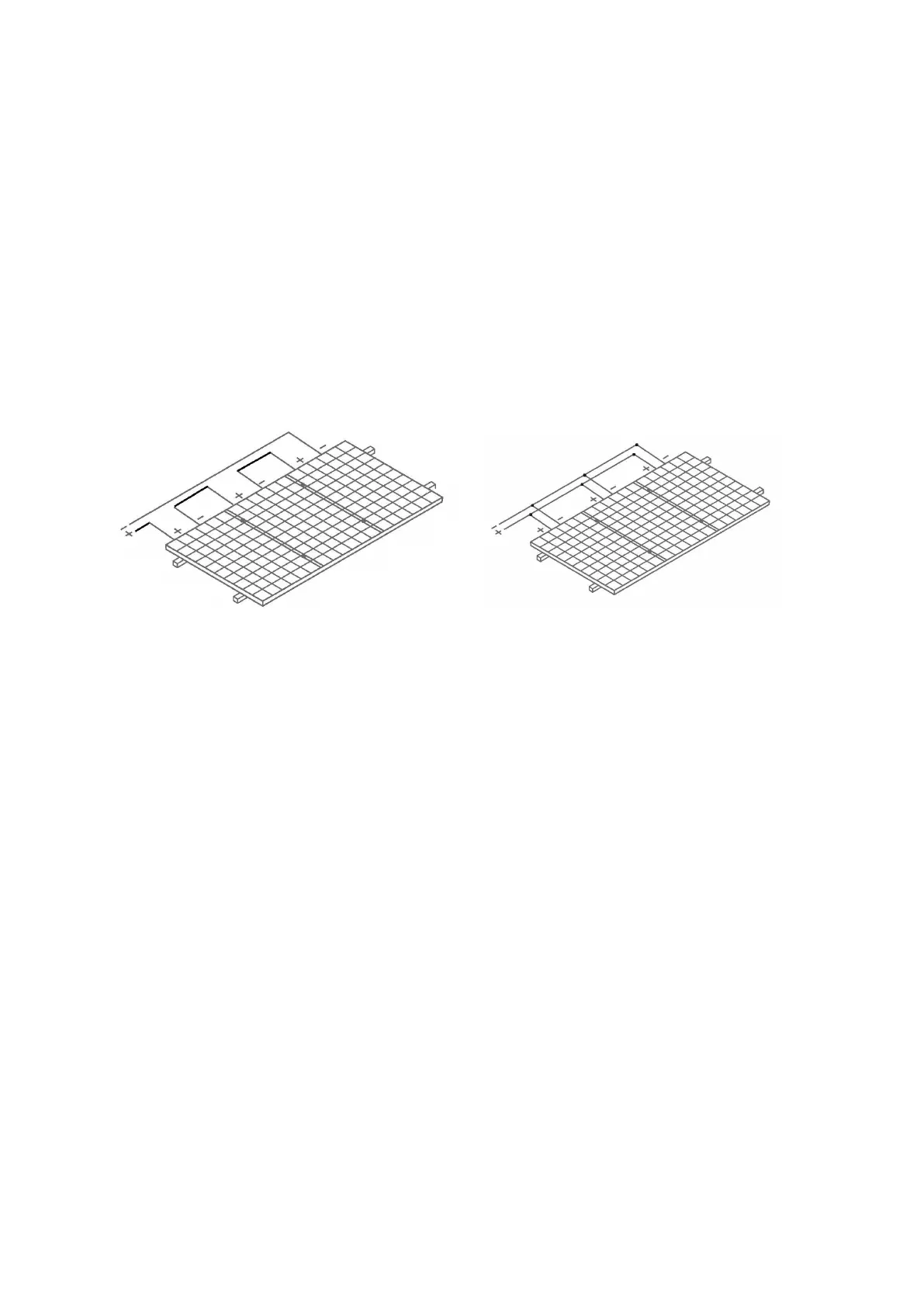

When connected in parallel, the current output is equal to the sum of each string’s current

(as shown in Figure 6). Fuse is necessary for each module string. Take reference to the

local regulation. Recommended maximum parallel Modules configurations: Fuse rating/

(1.25* short-circuit current).

Figure 5 Connection in Series

Figure 6 Connection in parallel

Refer to the local regulations to determine the system wire size, types and temperatures.

The cross section of the cables and the capacity of the connectors must be selected to suit

the maximum system short circuit current (The recommended section area for a single

piece of Module is 4 mm

2

, and the recommended rated current for the connector is greater

than 20A), otherwise the cables and connectors shall be overheated under large current.

Caution: The maximal temperature of the cable is 85 ℃ while the upper limited

temperature of the connector is 105℃.

Make sure the electric components such as the connectors and inverters are off-state during

the installation. To reduce lightning damage, the loop area should be kept as small as

possible when laying cables. It is recommended to use fuses in each string.

▐ 06 GROUNDING

6.1 Grounding by cable

• The grounding bolts must be made of stainless steel and be used in the specified grounding

holes. First, make the stainless steel bolt pass through the spring washer, cup washer, flat

washer, and star washer, and then insert through the grounding hole, flat washer and spring

washer on the frame. Finally, tighten with a nut. Caution: The upper limited temperature of

the conductor is 85 ℃ . As for the installation, refer to Figure 7.

6.2 Grounding by lugs

All the module frames and mounting structures shall be grounded according to regional and

national electricity regulations. Use recommended hardware to connect grounding cables

and fasten to the Module frames.

While using the metal structure, make sure the surface of the system have been

Loading...

Loading...