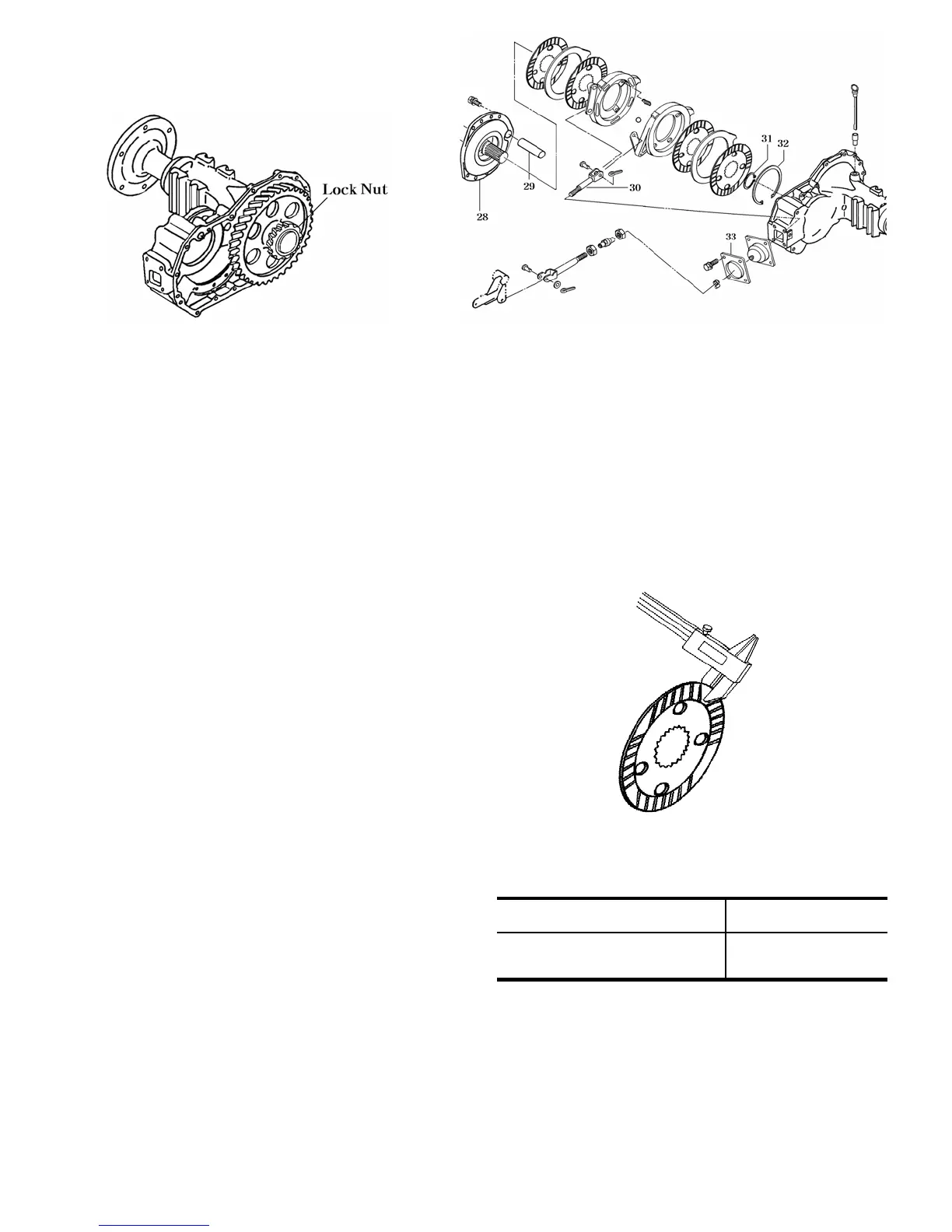

1.1 Disassembly

1) Release the lock of Nut and remove the nut

2) Extract the bearing with a puller and remove

wheel gear

3) Remove the collar and pull out wheel shaft(3)

Note:

Removed oil seal should be replaced with a new

one when reassembled

7-4

Fig.7-6

4) Detach the brake rod from actuator

5) Remove plate and the rubber boot

6) Remove the brake metal tightening bolts and

remove brake metal with wheel pinion and the

disc brake assembly on it

7)Remove the snap ring of wheel pinion

(Fig.7-6) And individually separate the friction

plates,actuator and separator plates from each

other.

6) The actuator can be disassembled by removing

Spring

Note:

Be careful to keep the friction surfaces of the linings,

Actuators and separator plates free from damage and

foreign matter.

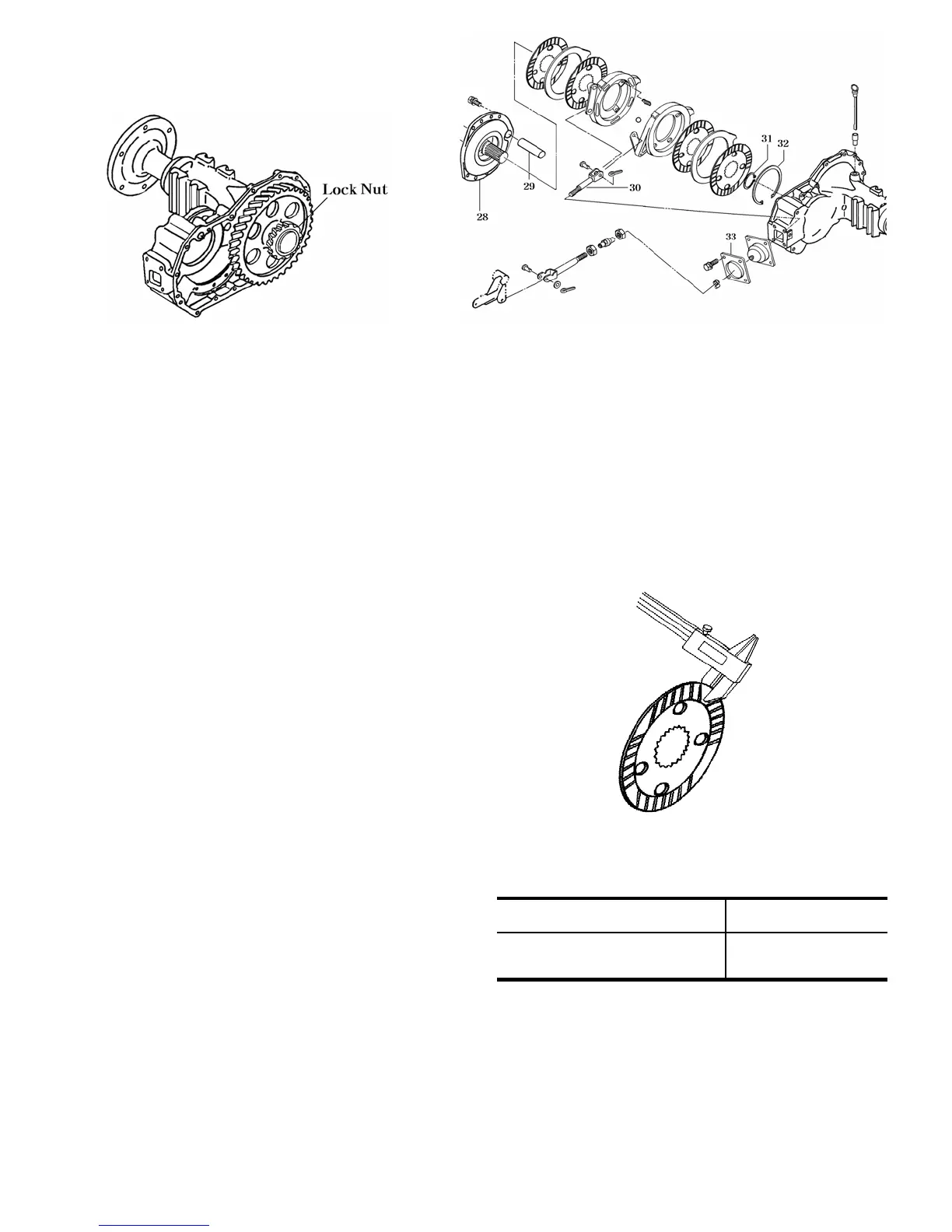

1.2. INSPECTION

1) Friction plates.

Replace the plates whose surfaces have been

become glossy by carbonization or whose

thickness exceeds the usable limit.

3.0 (0.118)Usable limit:mm (in)

3.4±0.1(0.134)Standard

thickness:mm(in)

Fig.7-7

Note:

Also replace those whose grooves have been

worn out completely even if only on one side

Fig.7-4

Loading...

Loading...