9-20

-Unloading valve(2) and related parts.

Install the spool and confirm that the returns

smoothly by the spring force after it is

compressed by pushing the stopper bolt end and

check that it slides smoothly.

-Pilot spool and related parts.

Be careful not to damage the O-ring during

pilot spool installation.After assembly,make

sure that the spool slides smoothly by pushing

the push rod.

4) Reassembly

-Inspection of the disassembled parts.

Place all the disassembled parts side by side on

a clean surface.Check o-rings for damage and

replace defective ones.Inspect the friction

surfaces of the spools,poppets,and casing for

flaws like scratches.Correct slight flaw with an

oil stone and wash corrected parts in a cleanser.

-Main spool and related parts.

When the head is disassembled,it should be

tighten and locked securely using adhesive.

Before retaining the spool with the snap ring E,

make sure that the spool slides smoothing

within the casing.

-Holding check valve and related parts

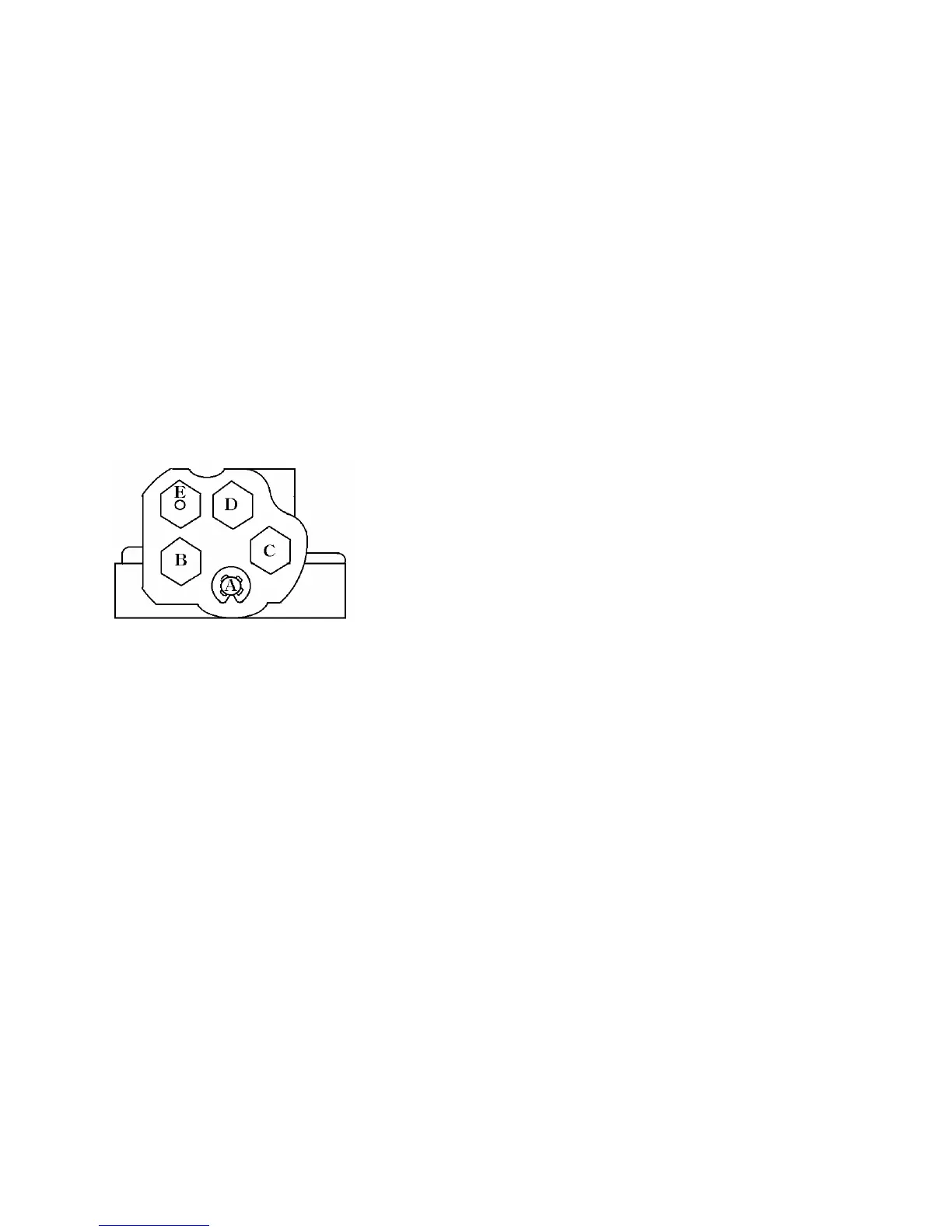

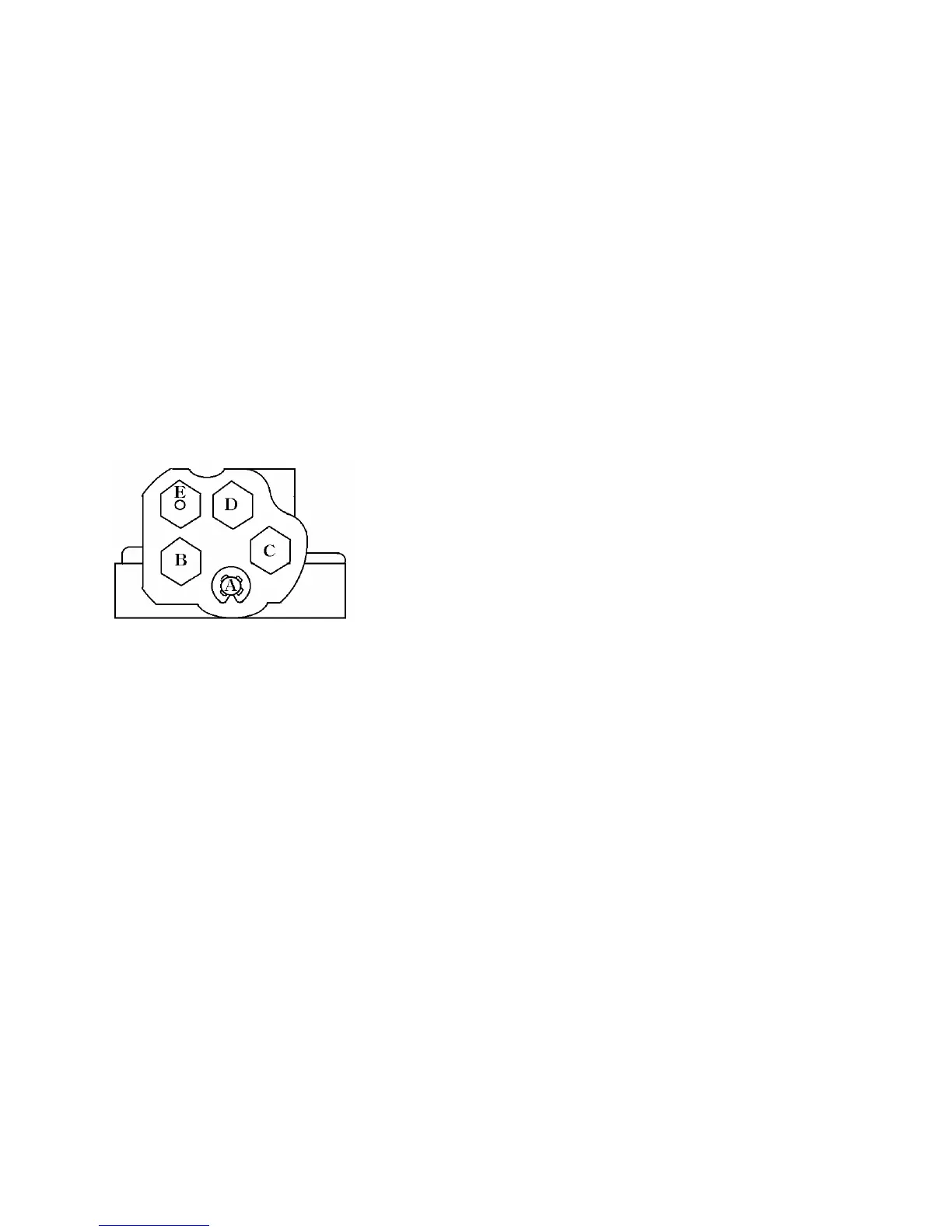

Fig.9-27 (A) Main spool hose

(B) Check valve’s hole

(C) Unloading valve-1’s hole

(D)Unloading valve-2’s hole

(E) Pilot spool’s hole

Put the poppet into hole B as shown in the figure and

make sure that the poppet slides smoothly.Then put

the spring in and tighten the plug,on which the O-

ring must be installed,to the specified torque.

-unloading valve(1) and related parts.

Install the spool into hole C(Fig.9-19) in the correct

direction.Put the spring in and tighten the plug to the

specified torque.

Loading...

Loading...