PAGE 1 OF 3 1211 IH-2708

OPERATION

TECHNICAL DATA

WARNING! Operator must read and understand

instructions here and on truck prior to use.

On the handle of the pallet truck, you will find the control

lever, which can be set in three positions.

(See Figure 1)

- LOWER = to lower the forks

- NEUTRAL = to move the load

- RAISE = to raise the forks

1. If the forks elevate while pumping in the NEUTRAL

position, turn the setting screw clockwise until

pumping the handle does not raise the forks and the

NEUTRAL position functions correctly.

2. If the forks descend while pumping in the NEUTRAL

position, turn the setting screw counter-clockwise until

the forks do not lower.

3. If the forks do not descend when the control lever is in

the LOWER position, turn the setting screw clockwise

until raising the control lever lowers the forks. Then

check the NEUTRAL position as per step 1 and 2.

4. If the forks do not lift while pumping in the RAISE

position, turn the setting screw counter-clockwise

until the forks elevate while pumping in the RAISED

position. Then check the NEUTRAL and LOWER position

as per steps 1, 2 and 3.

NOTE: When viewing the truck from the handle

side, the setting screw is located on the right

side of the pump above the right wheel. The

truck will lower faster or slower depending on

how far in or out the screw is adjusted.

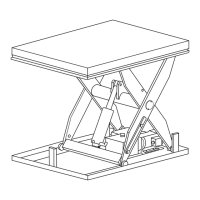

Figure 1

H-2708, H-2900

H-3045

INDUSTRIAL

PALLET TRUCKS

MODEL H-2708/H-2900/H-3045

Capacity (Lbs) 5,500

Max. Fork Height (In) 7.5

Min. Fork Height (In) 3.0

Fork Length (In) 48

Width Overall Forks (In) 27

Fork Wheel Diameter (In) 3" Polyurethane

Steering Wheel Diameter (In) 7" Polyurethane

Net Weight (Lbs) 186