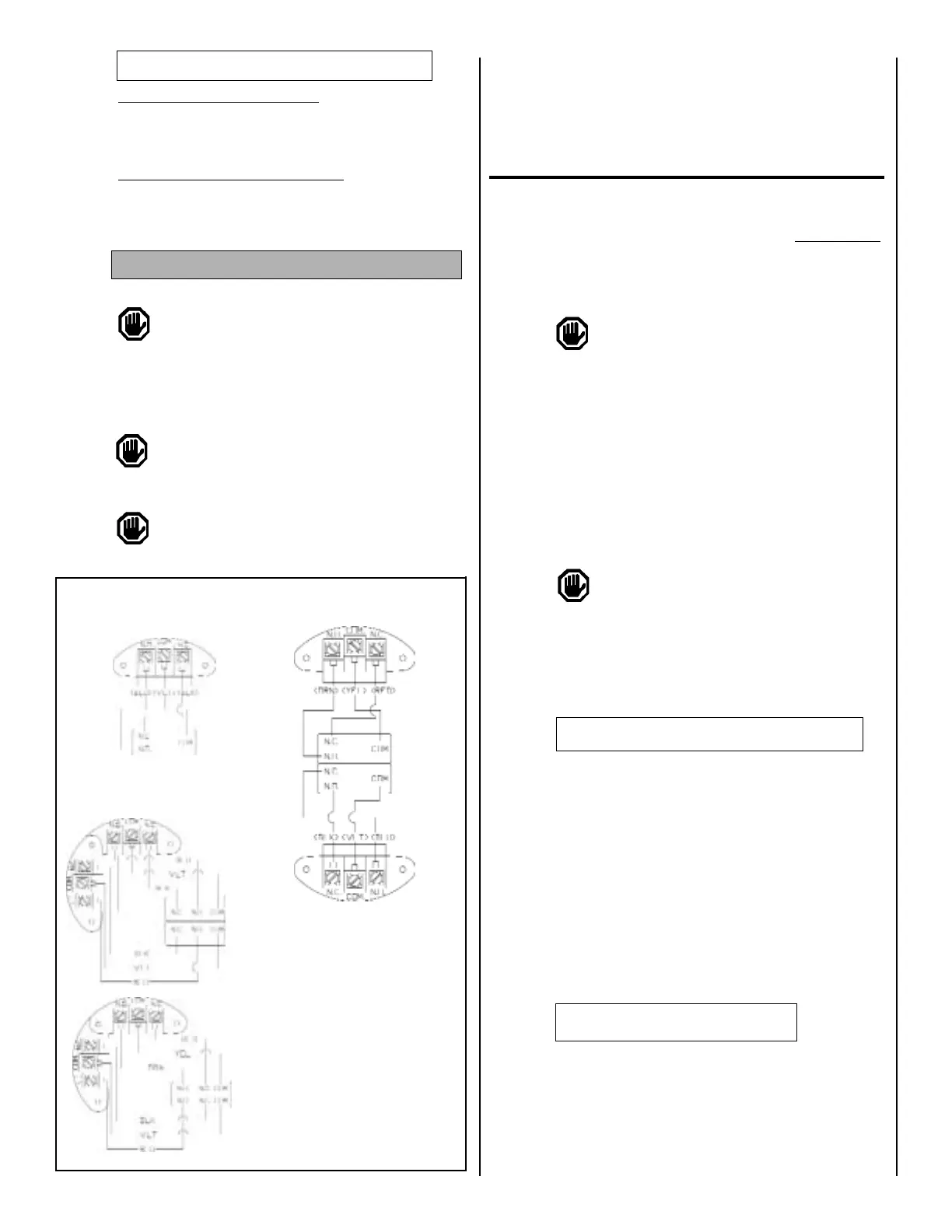

Remove cover and wire control (See Figure 3).

Replacing cover hand tight (a minimum of 5 full

threads engaged) is sufficient to maintain proper

protection. Additional tightening is required to fully

engage cover O-ring and seal enclosure to rain-

tight protection.

TOOLS NEEDED

Screwdriver

5/8” Open End Wrench

5/64” Allen Wrench

SOME MODELS HAVE A TWO-PIECE

ADJUSTABLE PLUNGER. THIS FEATURE

IS CHARACTERIZED BY A 3/16” HEX HEAD

SCREW INSTALLED IN THE PLUNGER. THE

LENGTH OF THIS ASSEMBLY IS ADJUSTED AT

OUR FACTORY AND IS CRITICAL TO THE FUNC-

TION OF THE CONTROL. DURING NORMAL

ADJUSTMENT, THESE COMPONENTS SHOULD

NOT BE DISTURBED. HOWEVER, WHEN

REPLACING THE ELECTRICAL SWITCH, IT MAY

BE NECESSARY TO ADJUST THE PLUNGER

LENGTH IN ORDER TO “RE-GAP” THE SWITCH.

REFER TO INSTRUCTIONS IN PART III -

REPLACEMENTS TO DETERMINE IF REGAPPING

IS NECESSARY.

AFTER COMPLETING ADJUSTMENTS ON

TYPE H121 AND H122 CONTROLS, BE

SURE TO RE-INSTALL ADJUSTMENT COVER. DO

NOT OVER TIGHTEN COVER SCREWS.

For set point adjustment and re-calibration, connect

control to a calibrated pressure source.

Types J120 (All) and J120K Models 455-559

Remove cover. Loosen slotted screw adjustment

lock. Adjust set point by turning 5/8” hex adjustment

screw clockwise (IN) to raise set point, or counter-

clockwise (OUT) to lower set point. Secure

adjustment screw by tightening adjustment lock

(see Figure 4a). Internal reference scales are

provided to show at which portion of the range (high

or low) the control is set. Re-calibration of models

50-55, S50B-S55B, 171-174, 183-189, 190-194,

471-474, 483-489, 490-494, 540-567, 680 & 701-

705 may also require the “re-gapping” of the space

between the top of the plunger and the bottom of

the microswitch. Use the flats on the plunger and

plunger hex screw as reference and follow the

gapping instructions on page 3.

Type J120K

Models 36-39,147-S157B, & 367

Remove front cover and gasket from sensor

assembly located below enclosure by unscrewing 4

slotted screws. Loosen slotted screw adjustment

lock (see Figure 4b). Adjust set point by turning

5/8” hex screw clockwise (IN) to increase setting or

counterclockwise (OUT) to decrease setting.

Adjusting screw should be locked by tightening

adjustment lock.

Controls with Breather Drain (Option M450)

Type J120, J120K Models 455-559

Mount with breather drain facing down and conduit con-

nection facing up (See Figure 1b). The conduit connec-

tion must be “potted” for this type of installation.

Types H121, H122 & H122P, All Models

Mount in vertical position with pressure assembly and

breather drain facing down (See Figure 1a).

WIRING

DISCONNECT ALL SUPPLY CIRCUITS

BEFORE WIRING UNIT. WIRE UNITS

ACCORDING TO NATIONAL AND LOCAL

ELECTRICAL CODES. MAXIMUM RECOMMENDED

WIRE SIZE IS 14 AWG. THE RECOMMENDED

TIGHTENING TORQUE FOR FIELD WIRING TERMI-

NALS IS 7 TO 17 IN-LBS.

ELECTRICAL RATINGS STATED IN LITERA-

TURE AND ON NAMEPLATES MUST NOT BE

EXCEEDED—OVERLOAD ON A SWITCH CAN

CAUSE FAILURE ON THE FIRST CYCLE.

TO PREVENT SEIZURE OF ENCLOSURE

COVER, DO NOT REMOVE LUBRICANT

(PETROLATUM). THREADS SHOULD ALSO

BE FREE OF DIRT, ETC.

Part II - Adjustments

Figure 3

Use 75°C copper

conductors only.

Recommended

tightening torque for

field wiring terminals

is 7-17 in-lbs.

Option 1010,

Type J120

Types H121, J120,

H121K, J120K

Types H122,

H122K

HIGH

TERMINAL

BLOCK

HIGH SET

(BACK)

LOW SET

(FRONT)

LOW

TERMINAL

BLOCK

Option 1180,

Type H122P

Loading...

Loading...