Types H121, H121K

Adjust set point by turning external knob and pointer

to desired setting on scale. Re-calibration (adjusting

set point after replacing microswitch): Slowly turn

adjustment knob until microswitch transfers.

Compare microswitch transfer point to actual pres-

sure. If they do not agree, loosen set screws on

adjustment knob with allen wrench and align pointer

to indicate actual pressure. Tighten knob set screws.

Types H122, H122K

Individual microswitches may be set together or apart

by up to 100% of range. When not set together, the

front microswitch can not be set higher than the rear

microswitch. Turning external knobs will increase or

decrease each switch setting independently. To

re-calibrate, follow procedure for Types H121 above

for each microswitch.

Controls with Options:

Option 1519, Adjustable Deadband Switch

This microswitch has an integral adjustment wheel.

Turning this wheel raises and lowers the pressure

rise set point. The fall set point remains constant.

Consult factory for additional information.

Type J120, Option 1530, Manual Reset

This microswitch, when actuated, remains actuated

until the pressure drops sufficiently to allow the reset

knob (located on the left side of the control) to be

manually turned to reset the microswitch.

Option M210 Indicator for

Differential Pressure Controls, Span Adjustment

(See Figure 5). To adjust indication for maximum

accuracy at any desired set point, follow steps 1 thru

4 listed below.

1) Remove front window and gasket (four screws)

to gain access to span adjustment.

2) Connect control to calibrated gauges and set

required differential pressure.

3) Using a screw driver, slowly turn the span

adjustment to obtain required indication

(See Figure 4).

4) Remount the front gasket and window.

Types H122P

Individual switches may be set together or apart by

up to 60% of range. The front switch is set by turning

the internal calibrating screw to the right for lower set

point and turning to the left for higher set point.

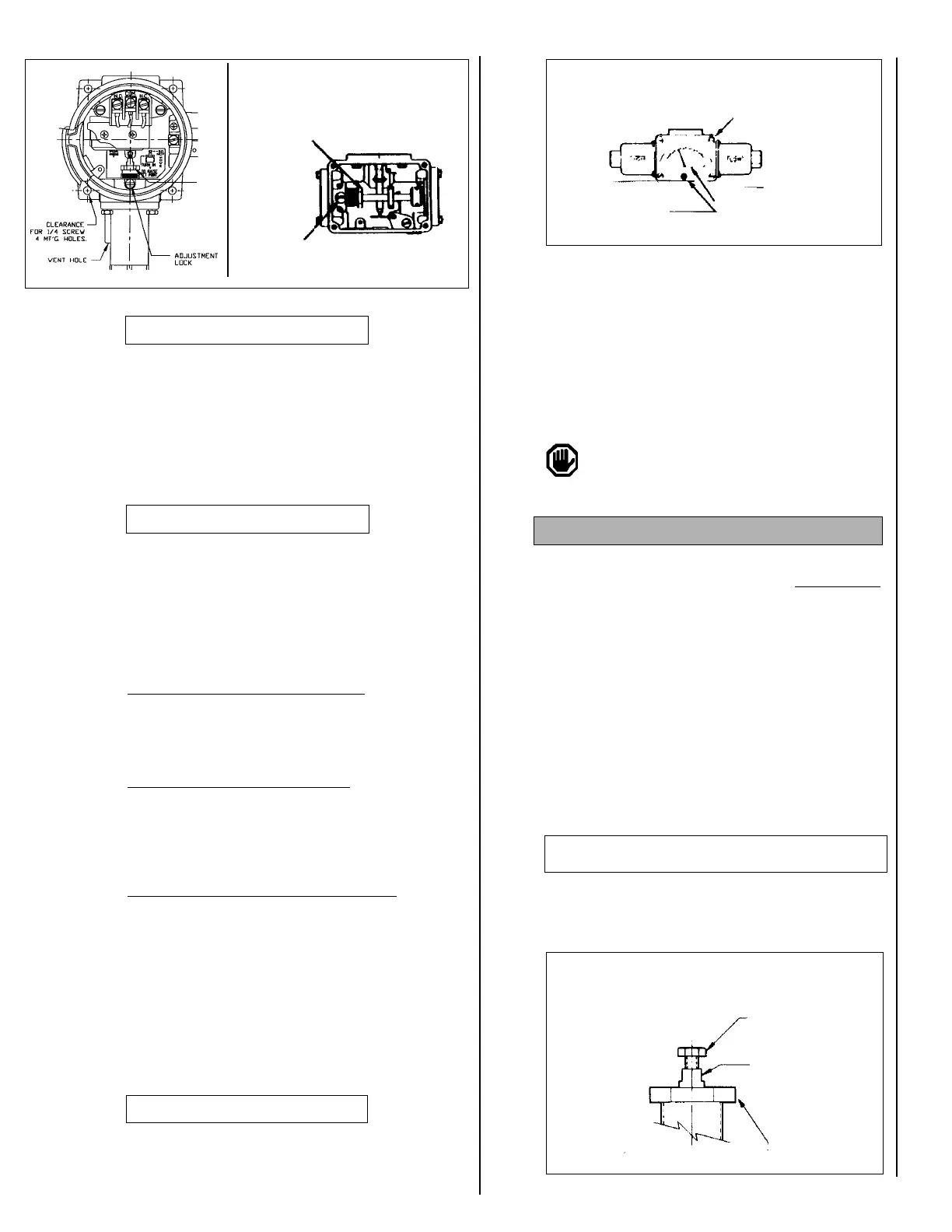

Figure 4a Figure 4b

J120K: Opposed Sensor,

Models 36-39, 147-157,

S147B, S157B, 367

Adjust Screw

Adjust Lock

When not set together, the front switch can not be set

higher than the rear switch. Turning the external

knob will increase or decrease each switch setting

simultaneously without disturbing their relationship.

NOTE: Spanning adjustment will not effect the mid-

range indication. The adjustment is factory calibrated

and sealed to indicate tampering.

DO NOT FORCE SPAN ADJUSTMENT,

SINCE PERMANENT DEFORMATION OF

THE LINKAGE MECHANISM MAY RESULT.

GAPPING PROCEDURE

TOOLS NEEDED

5/8” Open End Wrench

3/16” Open End Wrench (2)

1) Loosen adjustment lock.

2) Turn 5/8” hex adjustment screw IN, to approxi-

mately mid-range. This puts a load on the

sensor and exposes the plunger flats.

3) Using a 3/16” wrench on the plunger flats and a

3/16” wrench on the plunger hex screw, turn hex

OUT from plunger until microswitch actuates. If

microswitch has already actuated, turn plunger

hex screw IN until microswitch deactuates.

4) Continue per following instructions, depending

on model.

Models 50-55, S50B-S55B, 171-174 and 471-474,

521-525, 531-535, 540-548

Turn hex (IN) an additional 2 flats from this point

(approximately 1/3 turn). This will provide a

9-11 mil gap.

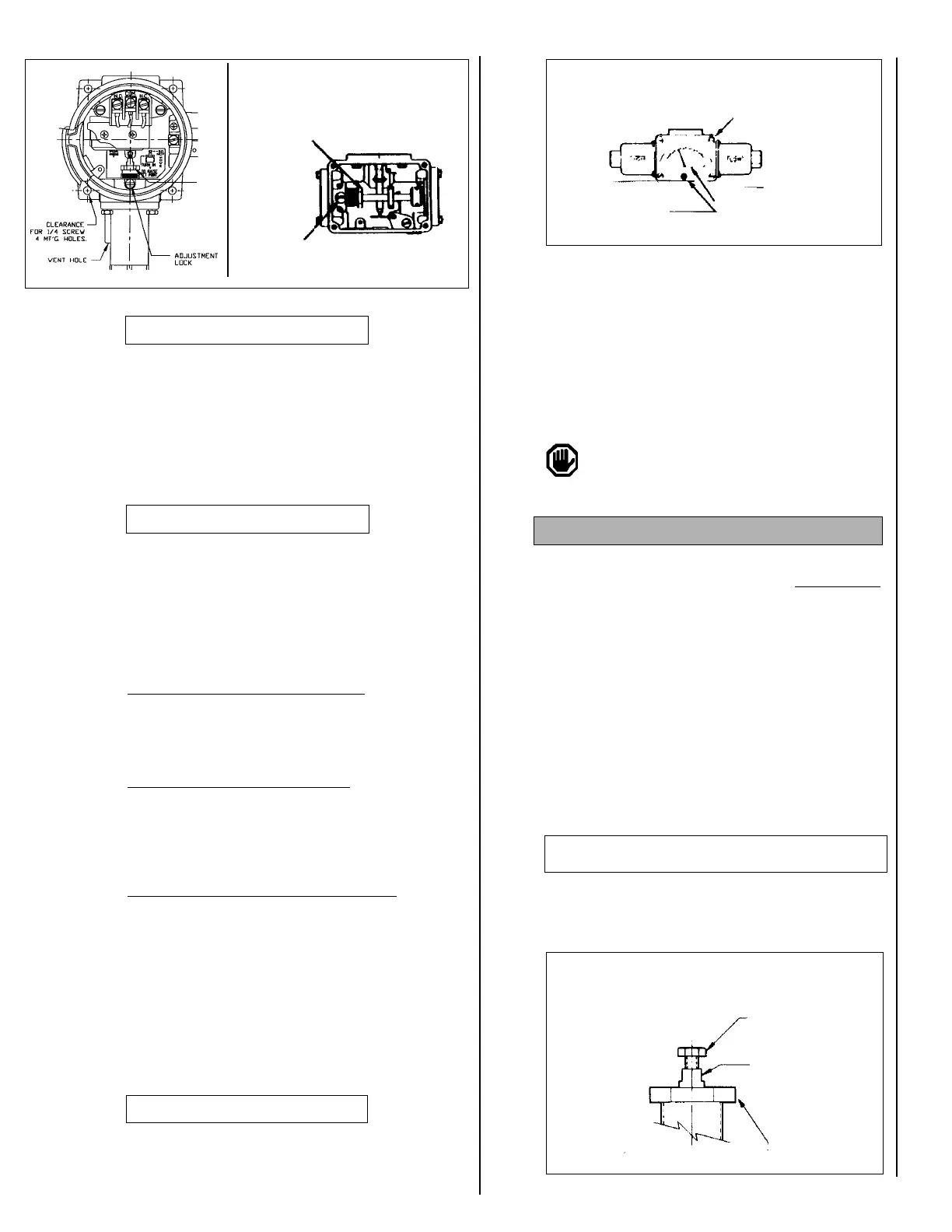

Figure 5

Adjustment Procedure for J120/J120K

Figure 6

Window Plexiglass

Span Adjust Screw

Window Mounting

Screw

Plunger Screw

Plunger Flat

Adjust Screw

Option M210

Loading...

Loading...