INSTALLATION

WITH CONNECTION

KIT

K24

(FIG.8)

to. typ.

C4

and CIO cabler

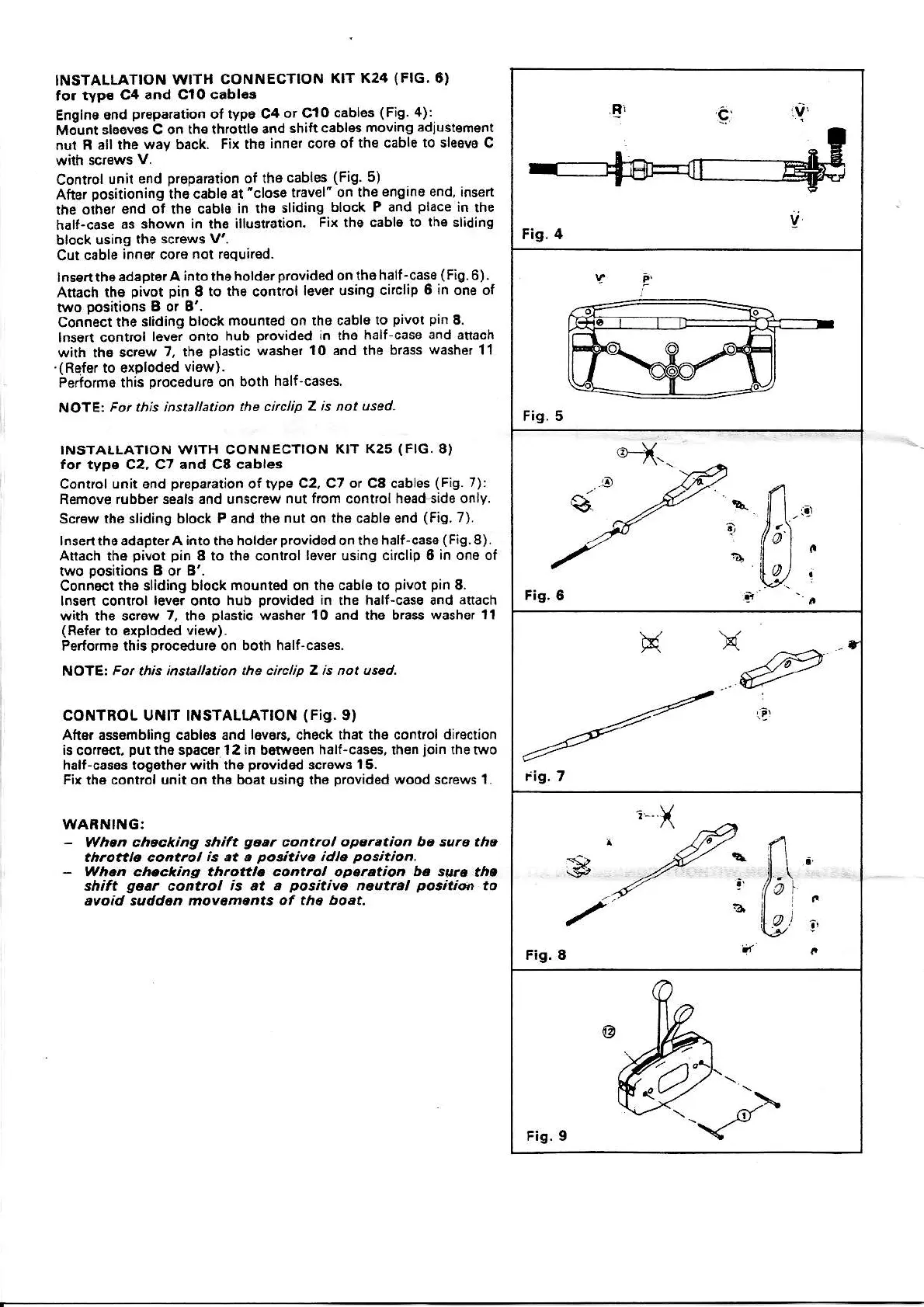

Enoine

end

preparation

of iype C4

or CIO cablos

{Fig.

4):

Mo,-unt sl66ves C on the lhronlo

snd

shift cablss

moving ädiuslern€nl

nut n

all lhe w.y back.

Fix tho

inner cor6 of lhe

cabl€ to sleovo

C

Conrrol

unit 6nd

prop.ralion

ol iho

cables

(Fig.

5)

After

oositioni6g

ths cäbl6 at

"close

lravel' on tha

enginB end iflsert

rhe oihor end

of

the cabl6

in lhe

sliding

block

P

and

place

in

the

hall-cas€

as shown

in

the

illustralion.

Fix lhe cäbl6

to the sliding

block

using

the screws

V'.

Cut cable

inn€l cor6

not r€quirsd-

lns€n the

adäptor A intothoholderprovided

on

tho half_case

(Fig

6).

Atach th6

pivot pin

I to the confiol

lever usiog

cnclip 6

in

ons ol

two

positions

B or B'.

Con;6ct

the 3liding

block mount€d on ths

cable

to

pivo!

pin

8.

lnson control

l6ver

onto

hub

provided

in the half-caso

and attach

with th6 screw

7, the

plastic

washer

10 and lhe brass

washer 11

.(Refer

to exoloded

vi6w).

eerforme this

orocedurs

on both

half cases

NOIE

For this instalanon

the circlip Z is not

used.

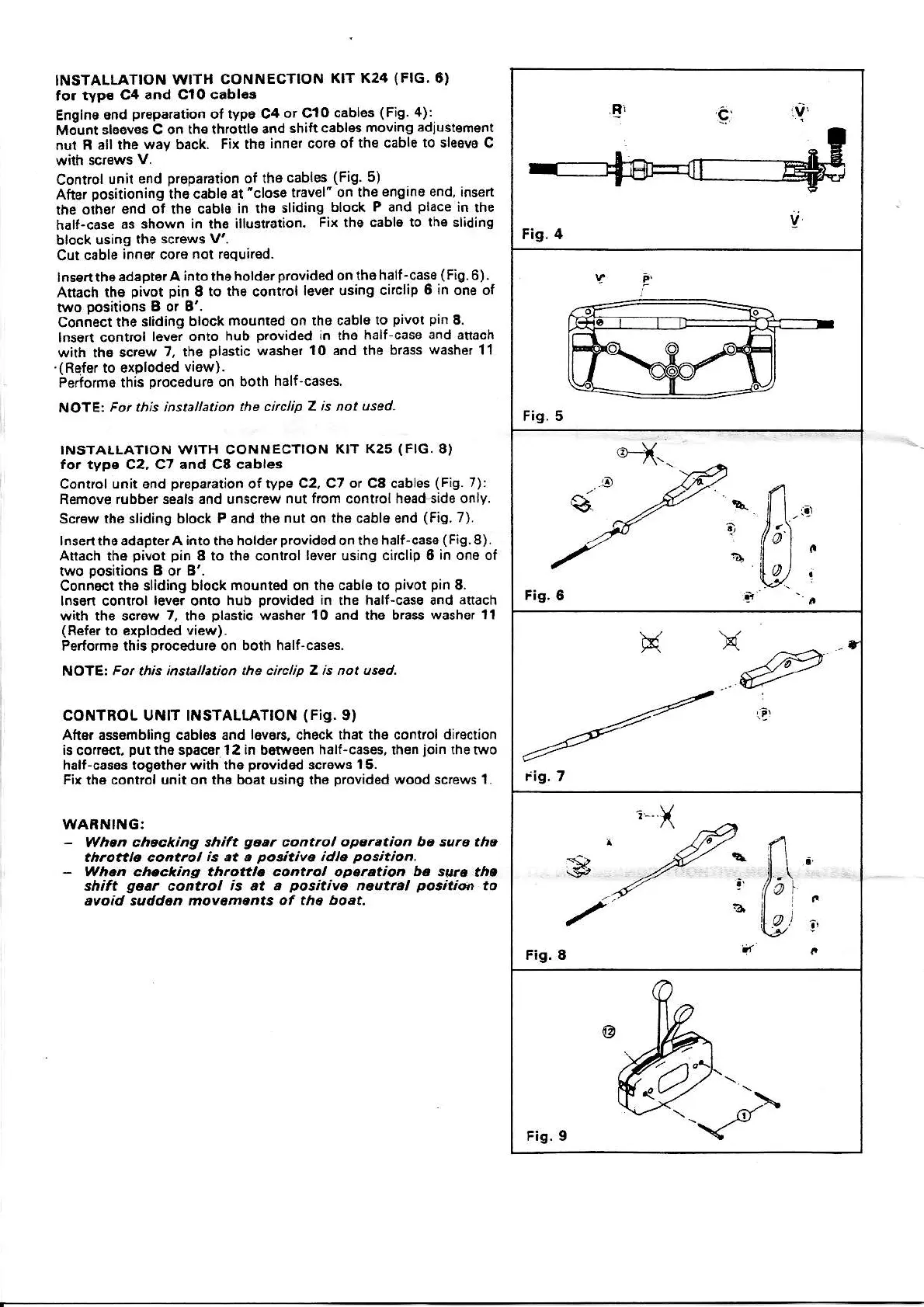

INSTALLATION

WITH CONNECTION

KTT K25

(FIG.

A)

for typs

C2,

C7 and C8 cables

Conlrol

unit end

prepaation

of type

C2, C7 or C8

cablos

(Fig.

7):

ßemove

rubber sgals and unscrew nut

frcm

control hsediide

only,

Sc.ew the sliding

block P and tho

nut

on the cabl€ end

(Fig.

7).

lnse.ttheädäpterA

into

the

holder

provided

on the half"cass

(Fig.8).

Aflach

the

pivot pin

8 to the control l6ver using circlip I

in one ol

tvvo

positions

B

or

B'.

Connoct rhe sliding block

mounted

on

rhs cabls to

pivoa pin

8.

lns6n contol

lever

onto hub

provided

in

the

half-c6se and anach

with th6 scrow

,,

tho

plastic

washer

10 and the b.a$ wäsher 11

(R€fsr

to exploded view).

Perform€ thb

procddu€

on borh

hälf-cases.

NolEt Fo. this installation the

circlip z is not used-

CONTROL UNlT ll,lSTALIATION

(Fis.

9)

Attqr ass€mbling cabl$ and

l6v6rs.

ch6ck that the conkol dkection

is

corrgct.

put

th6 spacar 1 2 in b{w6en half-cas6s, then

join

th€ two

halt-ca§8s tog6rh6. with rhe

provid6d

scr6w§

I

5-

Fir

the

control unit on th6 boat uaing th6

providod

wood

screws 1.

WAB ING:

-

Whcn checkiag thift

gt*tt

corrtrol

op.r.tion bc aura th.

thtottle conttol

is

at a

poritiyc

idl€

po§tiot

.

-

Wh.n ch.cking th.oalt. control opatation b. st ra rha

shift

ga.r

coatrol

is at e

positlva

aeutral

potitioi

to

ayoid sudd.n moveme,,ts of the boat.

Fis.5

Fis.6

X

iig.7

lt \

,

Fig.8

Fig.9

Loading...

Loading...