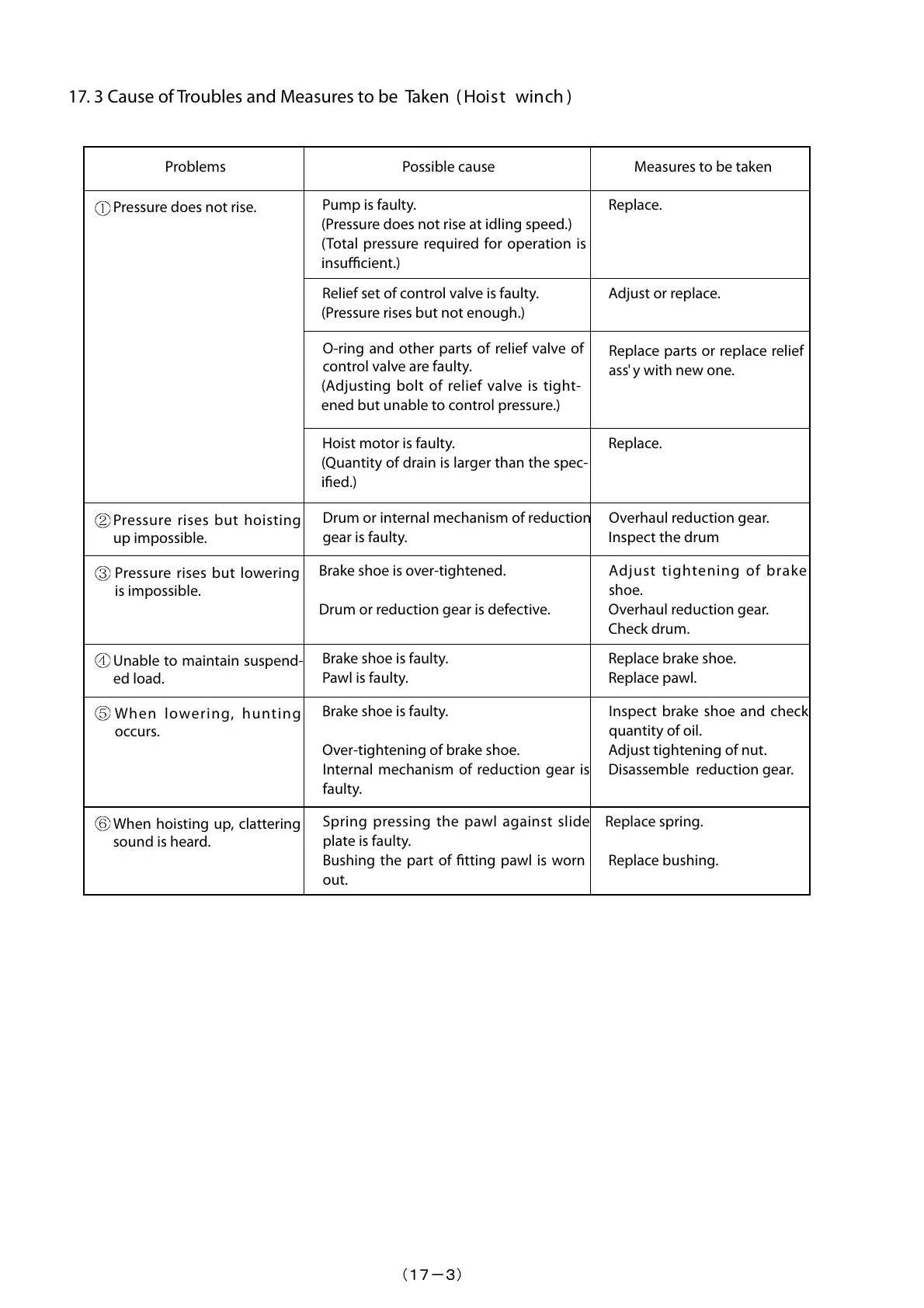

17. 3 Cause of Troubles and Measures to be Taken ( Hoist winch )

Problems Possible cause Measures to be taken

Pressure does not rise.

Pump is faulty.

(Pressure does not rise at idling speed.)

(Total pressure required for operation is

insucient.)

Replace.

Relief set of control valve is faulty.

(Pressure rises but not enough.)

Adjust or replace.

O-ring and other parts of relief valve of

control valve are faulty.

(Adjusting bolt of relief valve is tight-

ened but unable to control pressure.)

Replace parts or replace relief

ass' y with new one.

Hoist motor is faulty.

(Quantity of drain is larger than the spec-

ied.)

Replace.

Pressure rises but hoisting

up impossible.

Drum or internal mechanism of reduction

gear is faulty.

Overhaul reduction gear.

Inspect the drum

Pressure rises but lowering

is impossible.

Brake shoe is over-tightened.

Drum or reduction gear is defective.

Adjust tightening of brake

shoe.

Overhaul reduction gear.

Check drum.

Unable to maintain suspend-

ed load.

Brake shoe is faulty.

Pawl is faulty.

Replace brake shoe.

Replace pawl.

When lowering, hunting

occurs.

Brake shoe is faulty.

Over-tightening of brake shoe.

Internal mechanism of reduction gear is

faulty.

Inspect brake shoe and check

quantity of oil.

Adjust tightening of nut.

Disassemble reduction gear.

When hoisting up, clattering

sound is heard.

Spring pressing the pawl against slide

plate is faulty.

Bushing the part of tting pawl is worn

out.

Replace spring.

Replace bushing.

17-3

Courtesy of Machine.Market

Loading...

Loading...