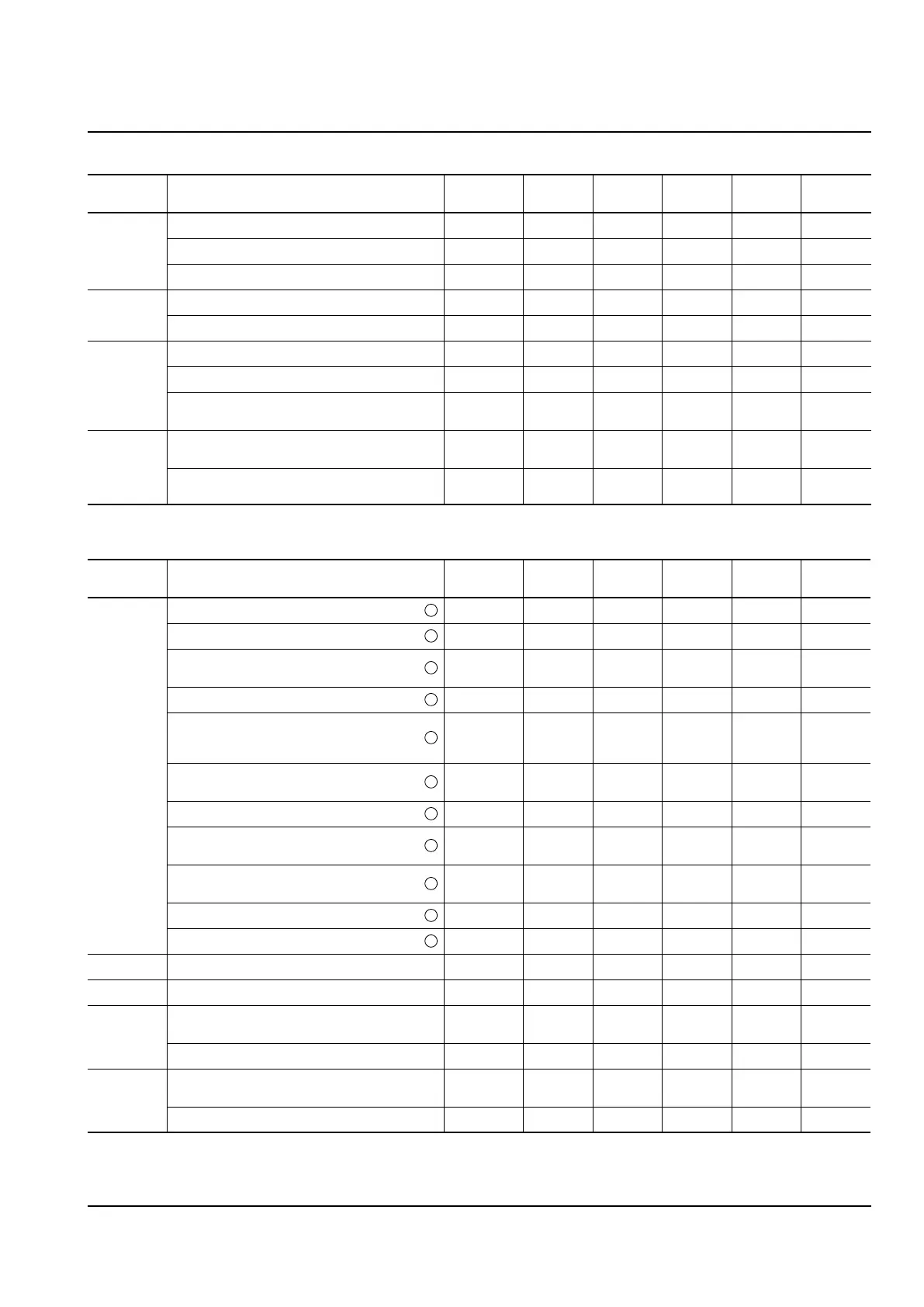

HYDRAULIC SYSTEM

Checking

item

Service Required Tools Daily

Monthly

(200 hrs)

Trimonthly

(600 hrs)

Semiannually

(1200 hrs)

Annually

(2400 hrs)

Hydraulic

oil tank

Check oil level and change oil, if contaminated. Visual

○ ○ ○ ● ●

Change suction strainer. Operate

● ●

Change return lter. Operate

● ●

Control

valve lever

Check for loose linkage of the lever. Operate

○ ○ ○ ○ ○

Check for function of the lever. Operate

○ ○ ○ ○ ○

Control

valve

Check for oil leaks. Visual

○ ○ ○ ○ ○

Check relief valve and tilt-lock valve for function. Auditory

○ ○ ○ ○

Measure relief valve pressure.

Oil pressure

gauge

○ ○

Hose,

piping, hose

reel, and

swivel joint

Check for oil leaks, looseness, deformation or

damage.

Visual/

touch

○ ○ ○ ○ ○

Change load handling hose. Operate

●

(1 – 2 years)

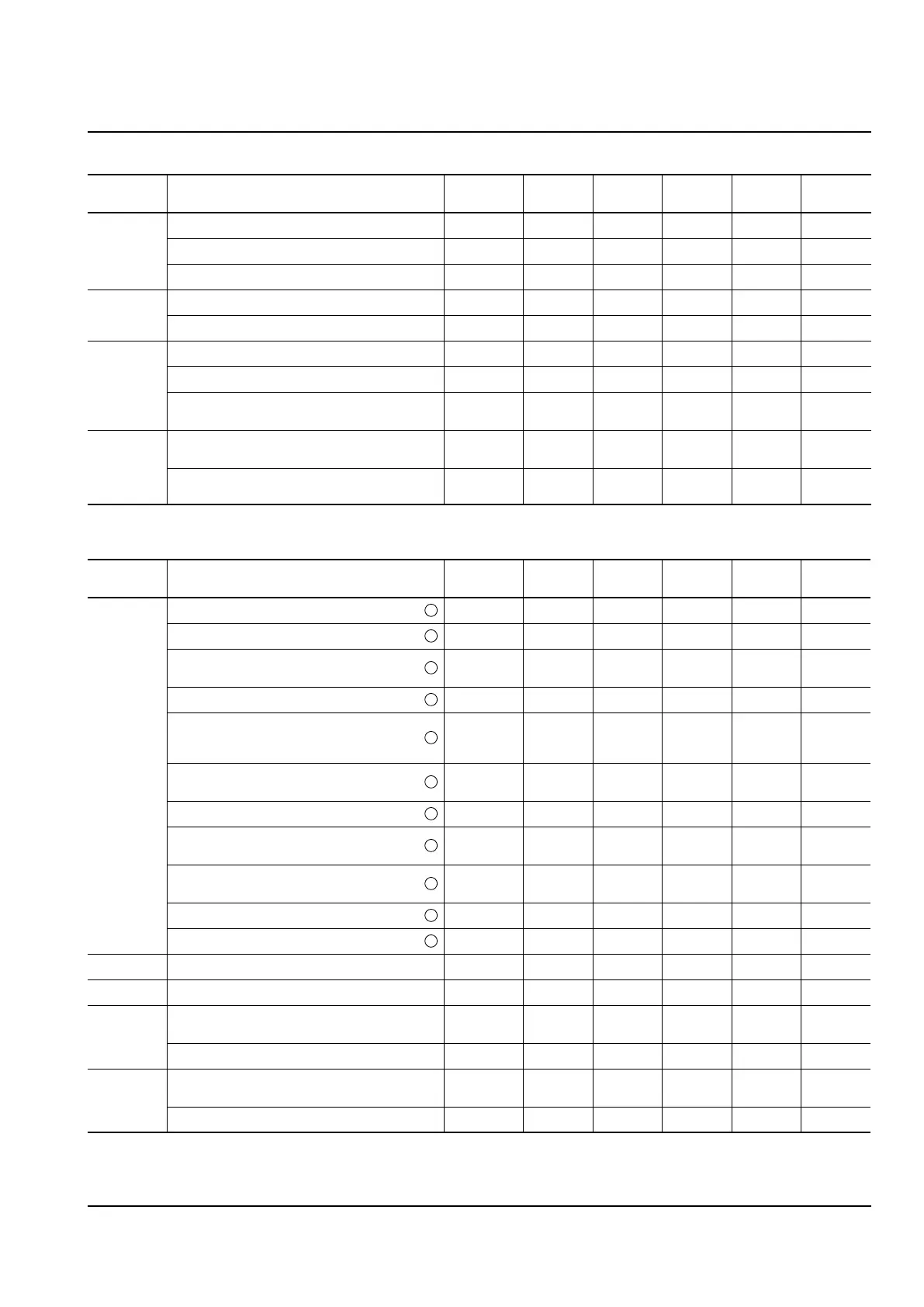

ELECTRICAL SYSTEM

Checking

item

Service Required Tools Daily

Monthly

(200 hrs)

Trimonthly

(600 hrs)

Semiannually

(1200 hrs)

Annually

(2400 hrs)

Ignition

device

(gas-

powered

trucks)

Check distributor cap for cracks.

G

Visual

○ ○ ○

Check spark plug for burn.

G

Visual

○

Adjust spark plug gap.

G

Plug gap

gauge

○ ○ ○

Clean spark plug.

G

Operate

○ ○ ○

Check spark plug and clean, adjust or

replace.

E

Operate/

plug gap

gauge

○ ○ ○

●

[every 18 months

(3600 hrs)]

Check the insertion of high-voltage

cable into distributor cap.

G

Visual

○

Check distributor segment for burn.

G

Visual

○

Check distributor center-piece for wear

or damage.

G

Visual

○

Check gap between signal rotor and

stator.

G

Thickness

gauge

○ ○ ○

Lubricate distributor shaft.

G

Operate

○ ○ ○

Check high-voltage cable for breakage.

G

Tester

○

Starter Check proper engagement of pinion gears. Operate

○ ○ ○

Charger Check for proper operation. Ammeter

○ ○ ○

Battery

Check electrolyte level and clean.

Visual/

operate

○ ○ ○ ○ ○

Check specic gravity of electrolyte. Gravimeter

○ ○ ○

Electrical

wiring

Check wire harness for damage and loose

clamp.

Visual

○ ○ ○ ○

Check for loose connections. Touch

○ ○ ○

4-46

Loading...

Loading...