- 36 - - 37 -

ENGLISH

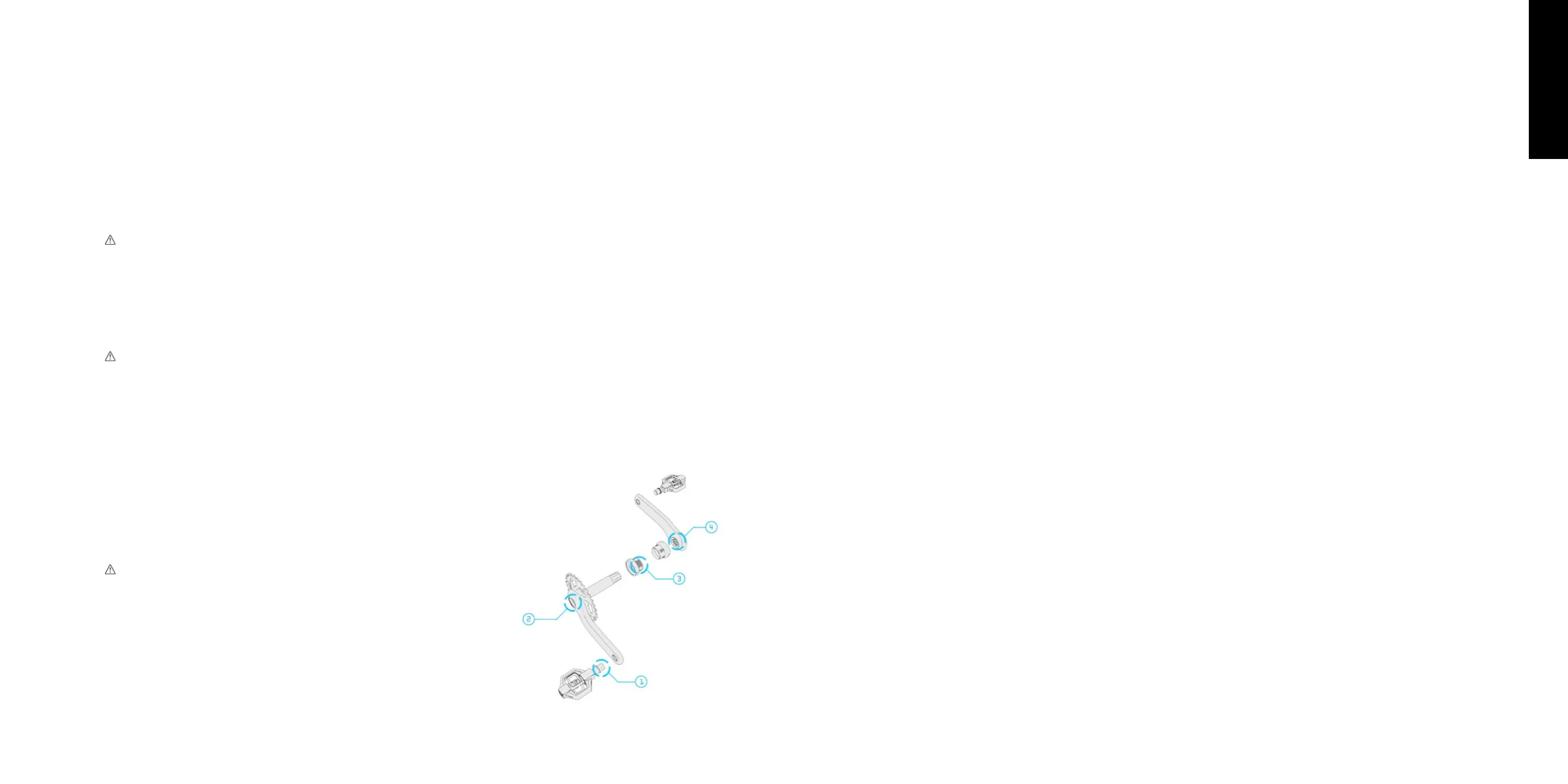

“L” the left one.

02. The left pedal has a left thread, meaning that you must turn the pedal in the opposite to the

usual direction (to the left).

03. Grease the threads of the pedals a little before screwing them into the cranks.

04. Screw the first two or three turns with your hand

05. Afterwards, use a special key for pedals, until they are completely screwed. Some types of

pedals require an Allen key for its mounting.

Lubrication

Once a year lubricate the bearings of the pedal, the mechanism of the automatic pedals and its

the thread to the cranks. Lubrication of bearings requires specific tools and knowledge and must

be done by a trusted mechanic. Some bearings are sealed, not needing lubrication.

To lubricate the threads of the pedals, disassemble them and reassemble them following the indi-

cations in the previous section. To lubricate the hooking mechanism of the automatic pedals, con-

sult and follow the instructions in the manufacturer’s manual.

04 | TRANSMISSION

The bicycle transmission set transfers the power to the rear wheel by means of the cranks, spin-

dle, chainring, chain and sprockets. For a complete view of the transmission, see also the section

“Gear Shifter”.

Inspection

When the transmission set works correctly, the gear shifter works smoothly and without noise.

Make sure that the sprockets, chainring and chain are clean and well greased.

Verification of the chain

Every 3 months check the chain to observe its wear. With the usage, the chain is stretched and

• Flat pedals with pins paired with shoes with extra soft rubber sole.

Inspection

Every 3 months inspect your pedals. Make sure that the pedals are securely attached to the

cranks. To do this, move the pedals from top to bottom and from left to right. If you notice that

they are loose or that the bearings are stiff, take the bicycle to your mechanic, to adjust, lubricate

or replace the pedals. You can find information on the tightening torques in the corresponding

section of this manual and in the manual of the pedal manufacturer.

In the event of a pedal loosening, the crank thread may be damaged, increasing the risk of a

fall.

If you mount automatic pedals, before using them, we recommend to clean both the shoe cleats

and the locking mechanism in the pedals, since the dirt could interfere the proper functioning of

the set.

Too much dirt could prevent you from detaching quickly enough from the automatic pedals and

cause a fall.

Adjustment

In most automatic pedals the force required to engage and dis-

engage the foot can be set by the mean of adjustment screws.

It is equally important the correct placement of the shoe cleats.

For more information on these settings, see the manufacturer’s

manual.

A too strong adjustment of the pedal hooks or an improper

mounting of the cleats on the shoes could prevent you from dis-

engaging quickly and cause a fall. It is recommended that the

placement of the cleats and the adjustment of the pedals is done

by a trusted mechanic.

How to mount the pedals on the cranks

01. Before mounting the pedal, note the letter that appears on

its axis. The letter “R” specifies the right pedal and the letter

Loading...

Loading...