- 40 - - 41 -

ENGLISH

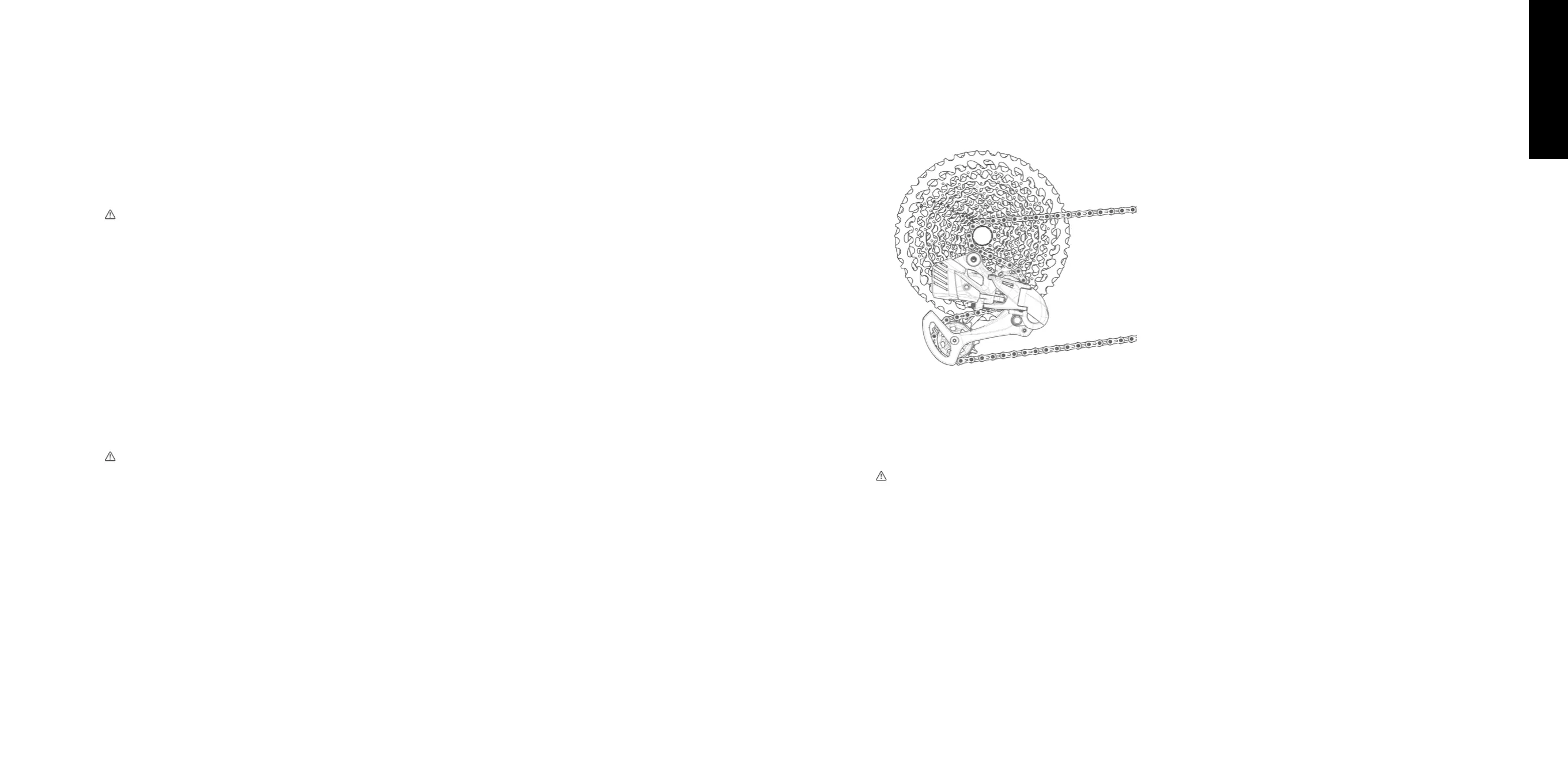

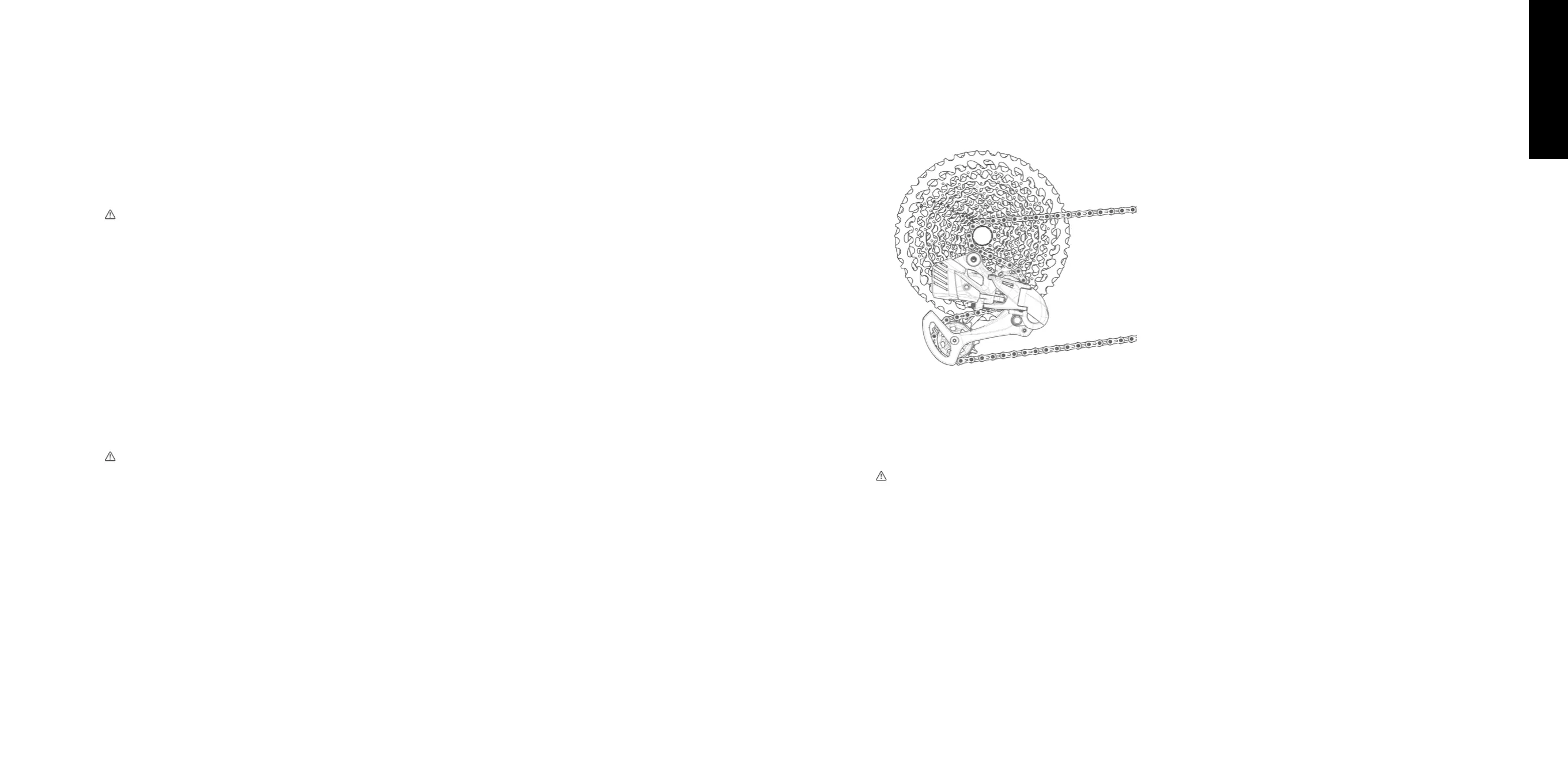

Check the operation of the shift lever once a month. With the rear wheel raised, slowly shift one

gear after another. The chain must run smoothly up and down all the sprockets, without going out

of the outermost or innermost sprockets.

Pay attention to the distance between the rear de-

railleur and the spokes, especially when the chain is

placed on the larger sprocket. Make sure the derail-

leur does not touch the spokes.

Every 3 months check the tightening torques of the

rear derailleur and the shift lever bolts.

• Derailleur: 6-8Nm

• Shifter Lever on the handlebar: 6-8Nm

Adjustment

It is recommended to make the adjustment of the

shifter, holding the bicycle firmly with a mounting

bracket that keeps the bike off the ground. Use a

specific support for carbon frames, which grip the bicycle by three interior points of the front tri-

angle, without pressuring on the tubes of the frame.

Do not fasten your bicycle with clamps that tighten around a carbon frame tube or seatpost, as

they could become damaged.

How to adjust the derailleur

To prevent the rear derailleur from becoming entangled with the spokes and the chain going out

of the smaller sprocket, you should limit the movement of the rear derailleur by the means of two

screws, which regulate the stops of the chain’s travel across the sprockets.

One screw (L- “Low Gear”) to adjust the inside limit and one screw (H- “High Gear”) to adjust the

outer limit. The location of these screws varies according to the model of derailleur. If necessary,

consult the manufacturer’s technical manual.

The adjustment process of the stops is the following:

04. Next, turn the chain several times and then leave your bike at rest for a few minutes so that

the lubricant penetrates the chain links.

05. Finally, with a rag remove the excess of oil to prevent dirt from depositing on the chain and

oil dripping on the soil while riding.

We recommend dispensing the oil drop by drop, but if you use a spray instead, always put a rag

behind the chain, chainring and sprockets, to prevent the oil from staining the bike, or even con-

taminating the brake discs or pads.

Make sure that there is no oil on the brake discs or pads. The brake would lose efficiency with

the consequent risk of fall.

05 | GEAR SHIFTER

When a gear shift is made, the rear derailleur turns and the chain derails, jumping from one

sprocket to another.

During this process it is recommended to decrease the pedalling force. To do this, select the cor-

rect gear just before starting an ascent or overcoming an obstacle. In this way the shifting oper-

ation is smoother and the wear of the chain decreases. Moreover, the chain might be caught be-

tween the chain stay and the chainring (“chainsuck” effect).

Avoid shifting gears while stomping hard on the pedals.

Inspection

When it is well adjusted, the shifter acts silently. If after shifting a gear, a noise happens for a

while, the shifter set may need to be adjusted.

Some Unno trail and enduro bikes can use electronic systems. If any issue happens, please head to

a trusted and qualified bike mechanic. Be specially careful when handling the electronic systems

and always use your transmission with a considerable battery range.

On the traditional mechanical tranmissions, it is recommended once a month to check that the

cable is not loose or twisted, has no rust, broken wires or damaged ends. Also check its sheath for

cuts and scuffs. If you think the cable is not on good conditions, do not ride before changing it or

taking the bike to a trusted mechanic.

Loading...

Loading...