The Utile Engineering Co. Ltd. 29/06/05

Irthlingborough, Northamptonshire. England

Tel: +44 (0) 1933 650216

Fax: +44 (0) 1933 652738 14 IC129

Reassemble rear end

6.13 Refit sliding blades (6) in their slots after lightly smearing with oil and removing any high spots with fine

emery cloth. Ensure the blades are orientated correctly in their slots.

6.14 Position the bearing seal (40) into position in the coverplate (3) ensuring that the tension spring is facing

the rotor for blowers and natural gas compressors and away from the rotor for vacuum pumps.

6.15 Press the outer race of roller bearing (18) into position in the coverplate (3).

6.16 Fit new o-ring (20) into the coverplate groove. If coverplate gasket (54) has been replaced, it is essential

that they are the same thickness as the originals, otherwise internal clearances will be affected and could

cause serious damage. Lightly smear the gasket with oil before replacing.

6.17 Place rear coverplate assembly onto cylinder (1) via location dowels and bolt with six screws (43) and with

coverplate gaskets (54) in place.

6.18 The whole bearing assembly can be locked onto the shaft with the bearing retaining washer (23) and the

circlip (37).

6.19 Press the shaft seal (22) into the end cap (4) with the tension spring facing the rotor.

6.20 The end cap (4) can now be fitted with the gasket (53) and any appropriate shims.

6.21 Position fan (15) on the shaft, with the set screw. Refit fancowl (16) onto supports with screws (44).

Check that the shaft rotates freely by hand before refitting lubrication system.

6.20 Reposition support plate (8) complete with oil pump assembly and tighten with clamp screw (45). Refit

drive pulley (28) and timing belt (30). Prime oil pipes before use.

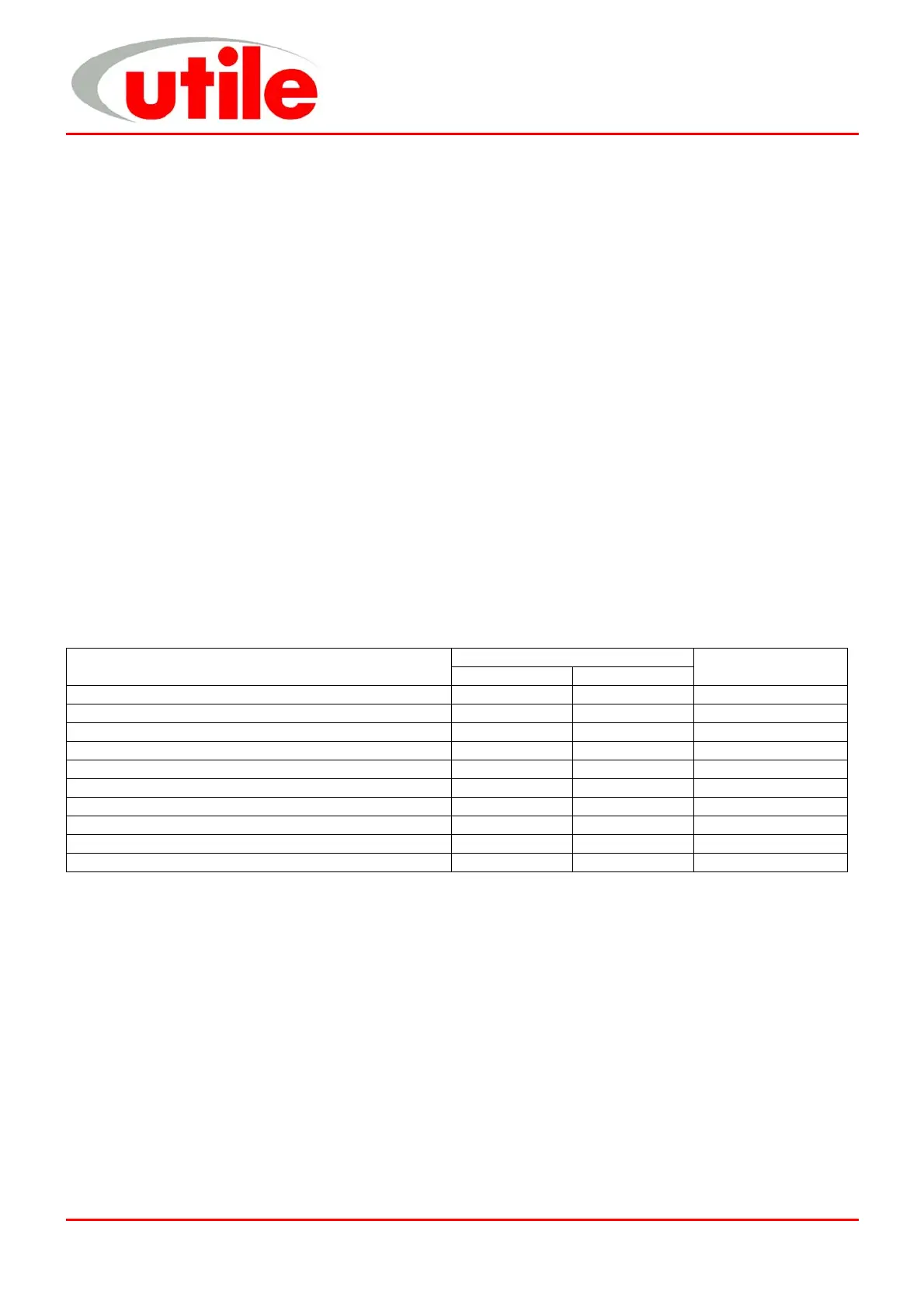

7. Spare Parts

A stock of the main wearing parts at the installation site is important to the constant availability and smooth running

of the machine. We recommend the following parts and quantities to be kept in stock at the installation site.

Part Number

Description

L240 L320

Quantity

Blade S 8808/1 S 8808/2 6

Roller Bearing H 1029 H 1029 2

Shaft Seal F 1089/V F 1089/V 2

Bearing Seal F 1067/V F 1067/V 2

O-Ring F 1071 F 1071 2

Gasket – Flange K 1015 K 1015 2

Gasket – Coverplate K 1033 K 1033 2

Gasket – End Cap S 8544/2 S 8544/2 2

Timing Belt P 1026 P 1026 1

Drive Belt / Drive Coupling 1 set

Always quote the machine serial number when ordering spare parts.

After Sales Service

Contact the address or telephone number shown at the bottom of each page or our local distributor, for any after

sales service, maintenance or service problems.

Contract maintenance, service exchange machines or a site visit by a Utile Engineering Service Engineer can also

be arranged in the same manner.

Utile Engineering can also provide Training Programs for all your requirements, from maintenance repair to

operator and supervisor training. They are structured to give specialist knowledge of our products and procedures

including use of authorised spares. The enacting of the Health and Safety at Work Act focused attention on the

responsibility of all parties, manufacturers, users and repairers on the repair of equipment. We strongly recommend

that repairs should be carried out to the original specification using authorised replacement parts where necessary.

Spare Parts

After Sales Service

Loading...

Loading...