Continuous level measuring system

NB 3000

Technical information / Instruction manual

page

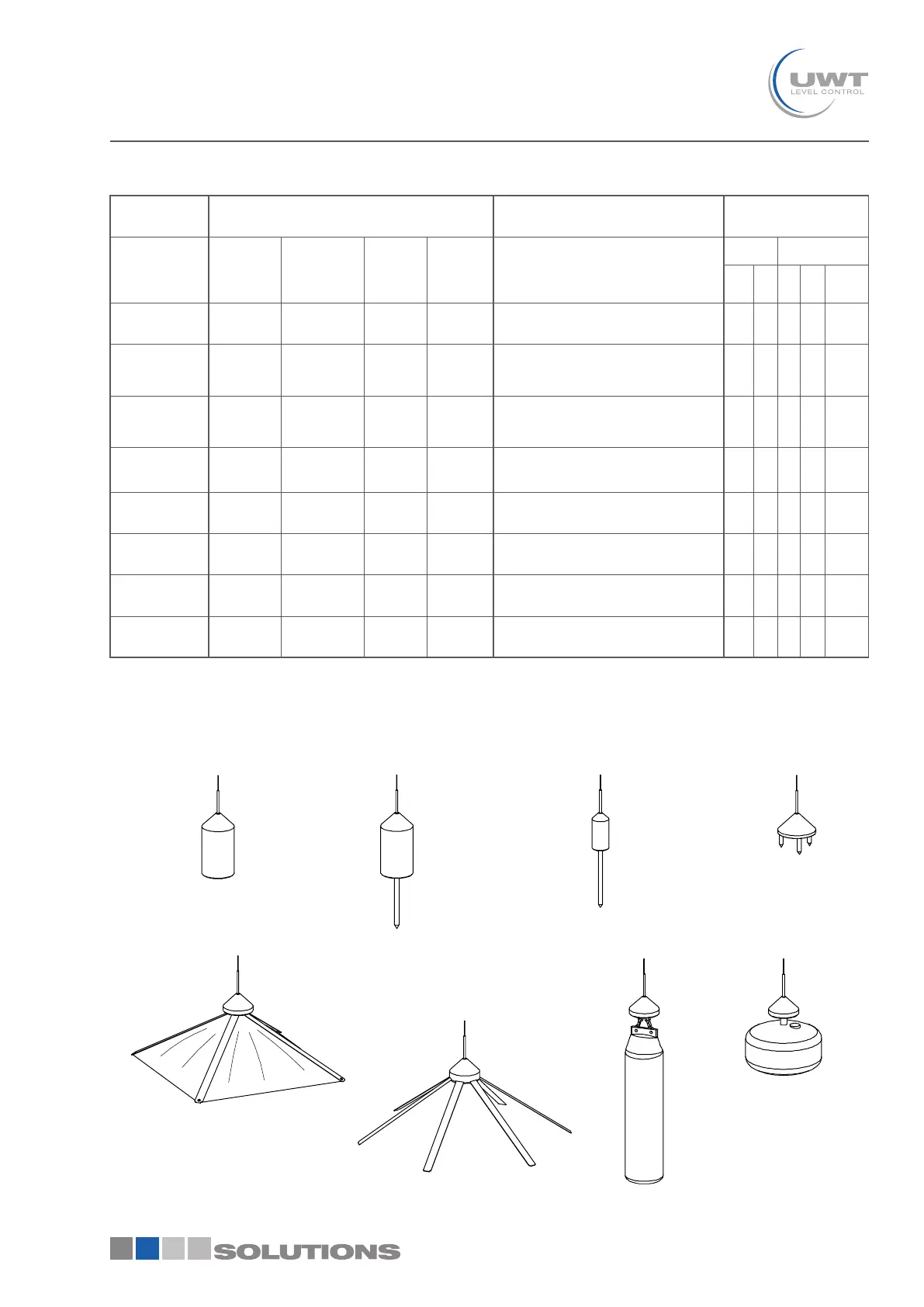

Sensor weight guide (solids measurement)

Technical data

Sensor weight Application Note Fits through mounting

hole

* Material

densitiy

g/l (lb/ft

3

)

Material

consistence

Angle of

repose

Max.

process

temp.

Thread Flange

1½" 3" 2" 3" DN100

/ 4"

PVC

without pin

>300

(18)

granulate at 80°C

(176°F)

Standard weight

•

PVC

with pin

>300

(18)

granulate,

powder

steep 80°C

(176°F)

The pin penetrates into the material and

avoids slipping or tilting of the sensor

weight on the steep bulk surface.

•

Stainl. steel >300

(18)

granulate,

powder

at,

steep

250°C

(482°F)

The pin penetrates into the material and

avoids slipping or tilting of the sensor

weight on the steep bulk surface.

• • • • •

Claw >200

(12)

coarse (e.g.

stones)

steep 250°C

(482°F)

Avoids slipping or tilting on the steep bulk

surface.

•

Folding cover >20

(1.2)

light powder at,

steep

80°C

(176°F)

Big surface prevents the sensor weight from

sinking into the material.

• • • • •

Spider >40

(1.4)

light powder at,

steep

250°C

(482°F)

Big surface prevents the sensor weight from

sinking into the material.

•

Bag >300

(18)

granulate,

powder

at 80°C

(176°F)

Prevents damage of the conveying screw.

To be lled with bulk material.

•

Float - liquids only - 80°C

(176°F)

To be lled with material.

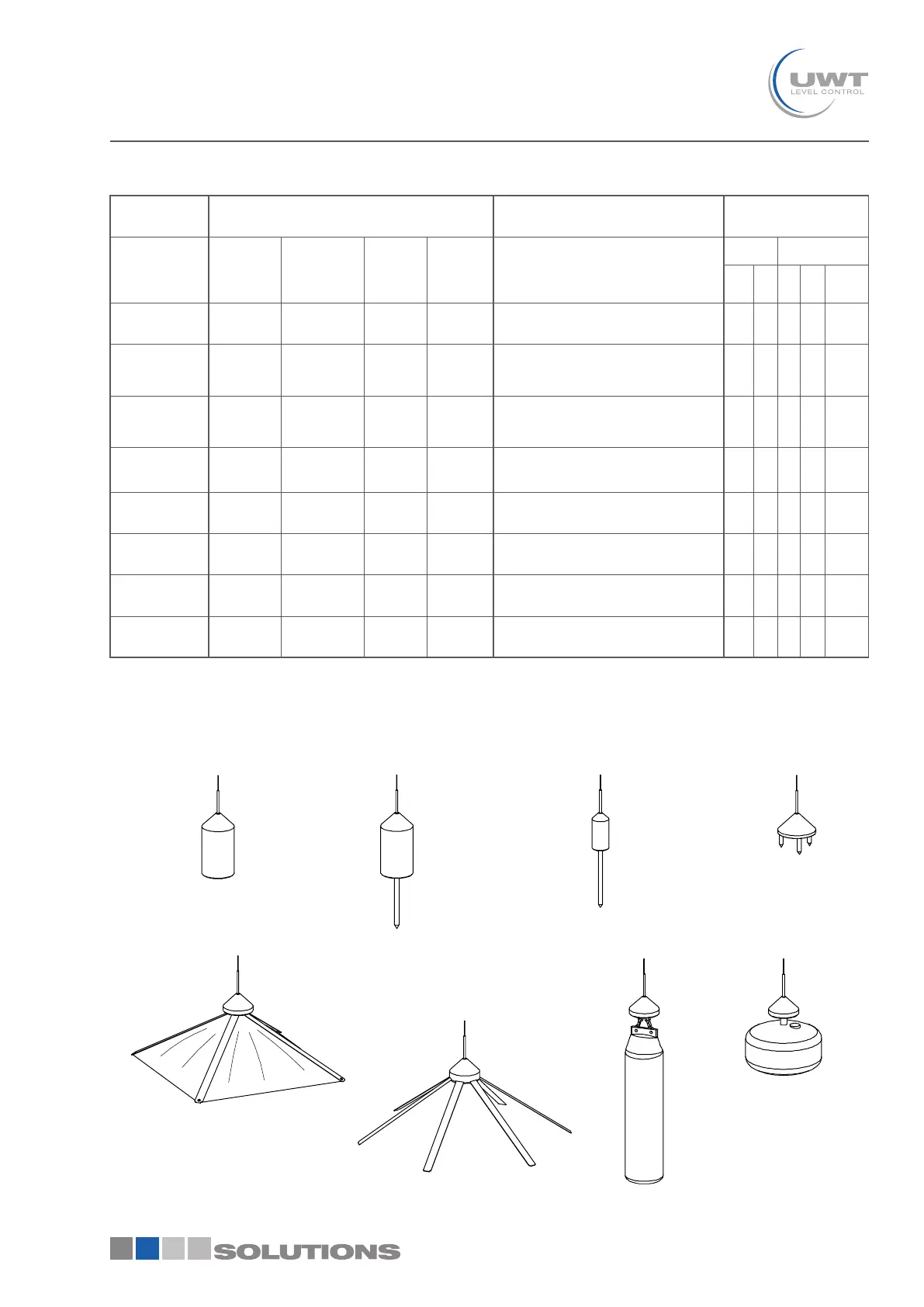

PVC

without pin

Stainless

steel

Claw

Folding

cover

Spider

Bag

Float

PVC

with pin

* The above mentioned data is a guideline and is valid for material which has settled after lling.

During the lling the bulk density can change (e. g. for uidised material).

Nivobob

®

1

2

3

4

5

6

7

8

9

10

11

12

NB 3000 b

gi020116

11

Loading...

Loading...