Set and check manifold pressure and

aeration

Set the manifold pressure.

1. Access the valve on the left hand side of the

appliance case.

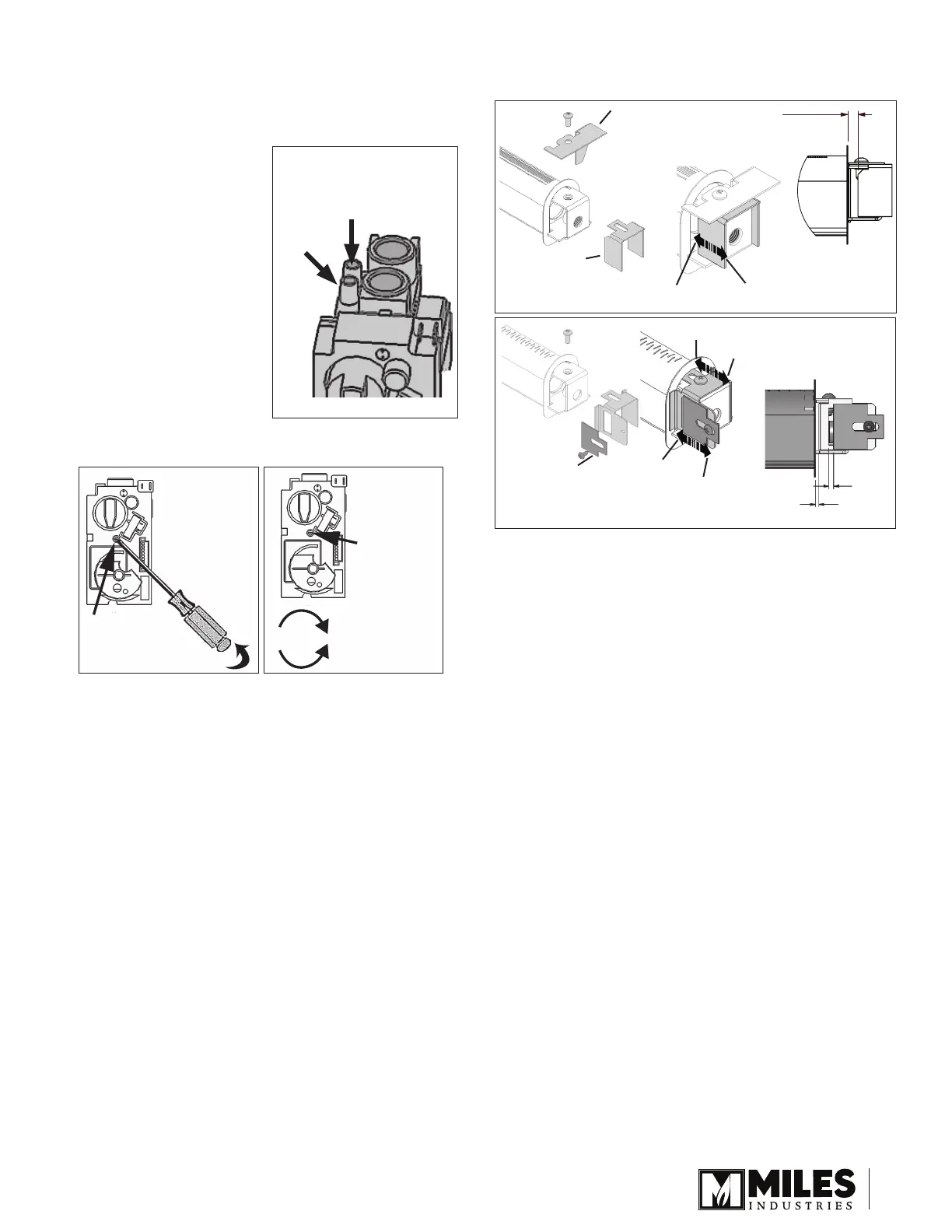

2. Fit a manometer to the

manifold pressure test tap

on the valve—see gure

at right.

3. Light the appliance and

turn the control to full

input.

4. Adjust the pressure

adjustment screw using

a small jeweller’s size at

blade screwdriver—as

shown below—while the

appliance is running at full

input to produce manifold

pressure, as per Specications table on page 1.

Manifold Pressure

Test Tap

Valve Inlet

Pressure

Loosen screw to check

(tighten afterwards)

Pressure Test Tappings

Front Face of

Control Valve

Pry off

plastic cap

Front Face of

Control Valve

Pressure

adjustment

screw behind

plastic cap

Increases pressure

Decreases pressure

5. Check the aeration and adjust the air shutter if

necessary.

6. Turn off the appliance, remove the manometer and

tighten the test tapping screw. Check for leaks.

7. Fit the label “This control has been converted...” on

the left hand side of the appliance near the valve.

8. Ret the valve access panel (5 screws).

Reinstall the replace components

To reinstall the components removed for the conversion

or to complete the installation of the replace, see the

installation instructions supplied with the appliance.

1. Ret the ceramic panels rst, then the front brick

support and the rear log support (3 screws).

2. Reinstall the grate (with logs only), the fuel bed, the

window, the front trim and the left side access door.

Fit the conversion labels

1. Fit the conversion label with new specications over

the corresponding specications on the data plate

attached to the replace at right hand side between

the rebox and the outer case of the appliance.

2. Fit the label “This appliance was converted on...

by...” near the data label tted in 1.

3. Reinstall the right side access door.

Designed and Manufactured by / for

Miles Industries Ltd.

190–2255 Dollarton Highway, North Vancouver, BC, CANADA V7H 3B1

Tel. 604-984-3496 Fax 604-984-0246

www.valorreplaces.com

© Copyright Miles Industries Ltd., 2012

738NG

3000220

4000682

738LPG

3000220

739NG

739LPG

6

mm

AERATION GAP

0

mm

AERATION GAP

3000220

3000220

4000682

0mm AERATION GAP

2

mm

AERATION GAP

6

mm

AERATION GAP

3000371

320B293

6

mm

AERATION GAP

3000371

320B293

Jun 2008

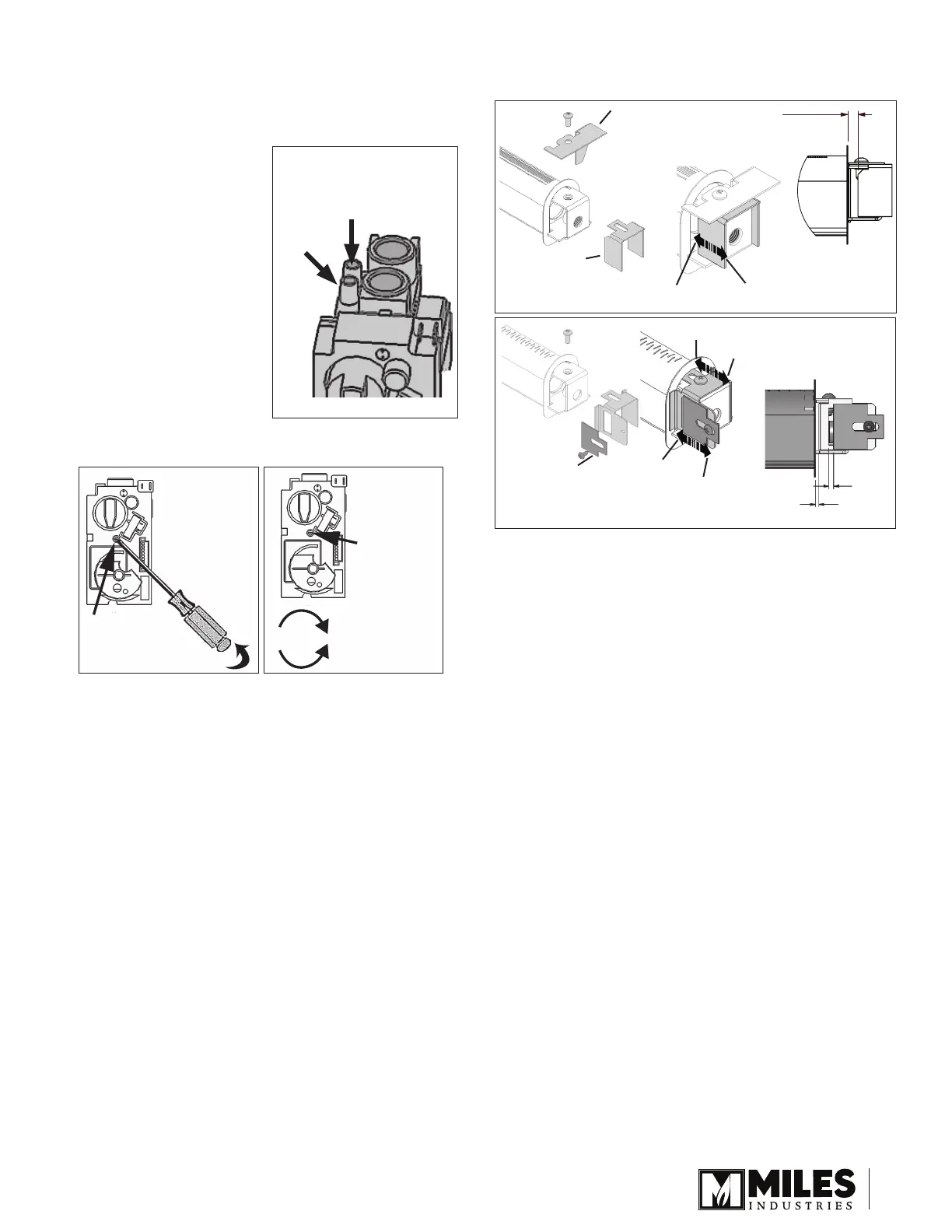

Flashback

shield

LPG Air Shutter

Slider

Open

Close

LPG

Open

Open

Close

Close

NG

NG Air Shutter

Slider & Cover

0 mm

3 mm-logs

7 mm-rocks

Aeration Gap

logs: 5 mm

rocks: Fully open

3

Loading...

Loading...