37

Model Code Page

21. Engine

205-- 555 210 17

1. 12. 1986

The flywheel (6) is fitted to the rear end of the crankshaft. The

ring gear (7) is fitted to the flywheel with a press fit. The forged

connecting rod has an I ---shaped cross---section. The bear-

ing location at the bottom end of the connecting rod is split,

and the bearing cap is secured by two special bolts (23) and

nuts (24). The upper end of the rod has a fixed bearing loca-

tion, in which the piston pin bearing bushing (22) is fitted with

apressfit.

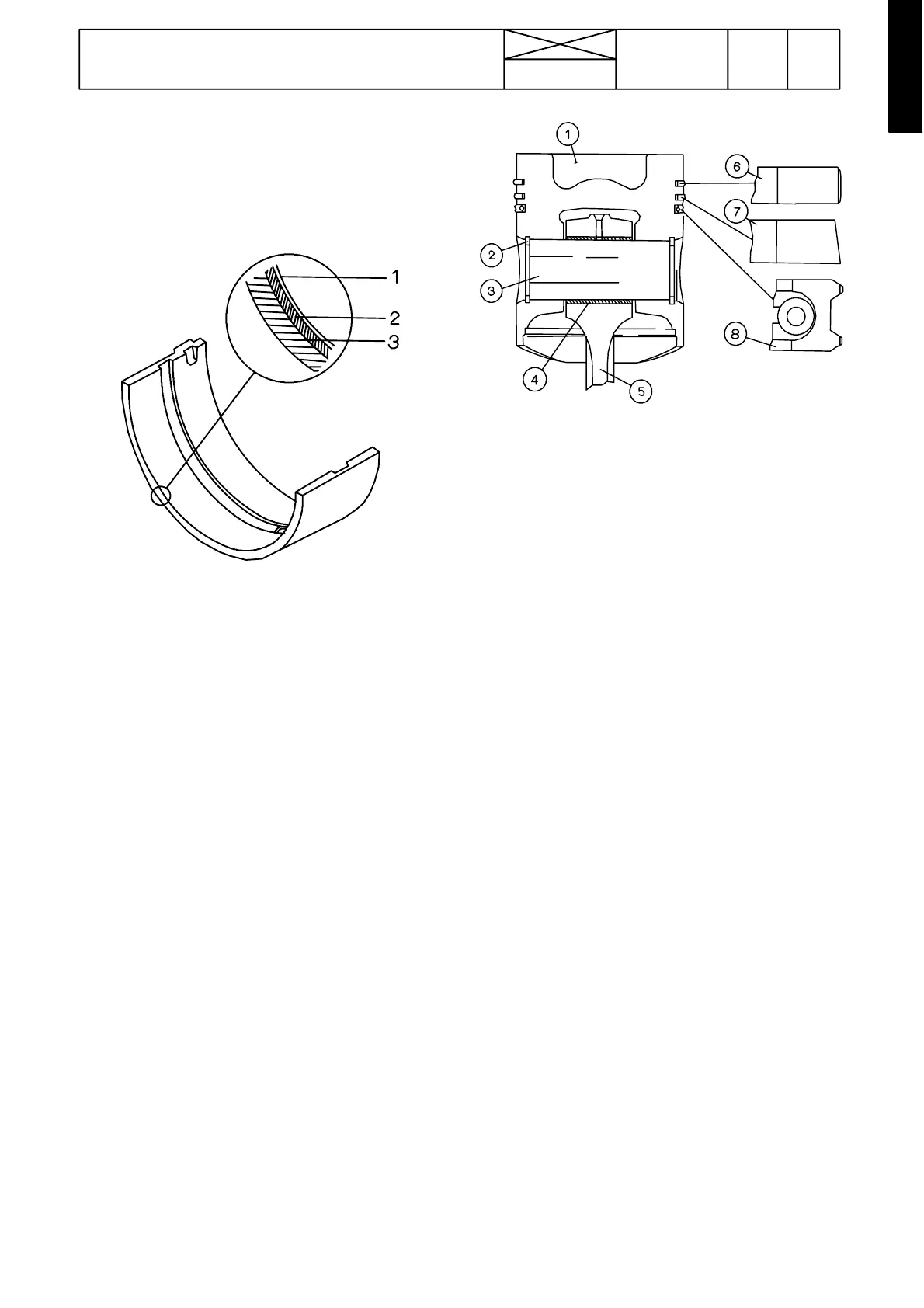

Bearing shell

1. Indium---lead alloy

2. Lead---bronze

3. Steel shell

The crankshaft has four main bearings, one on either side of

each cylinder. The thrust bearing is located on either side of

the rear main bearing journal. The main and big---end bear-

ings are three---layer bearings, which have a tough lead

bronze alloy, with good heat dissipating properties, inside the

steel shell. The actual sliding surface is covered by a layer of

indium---lead, which makes the running---in period easier.

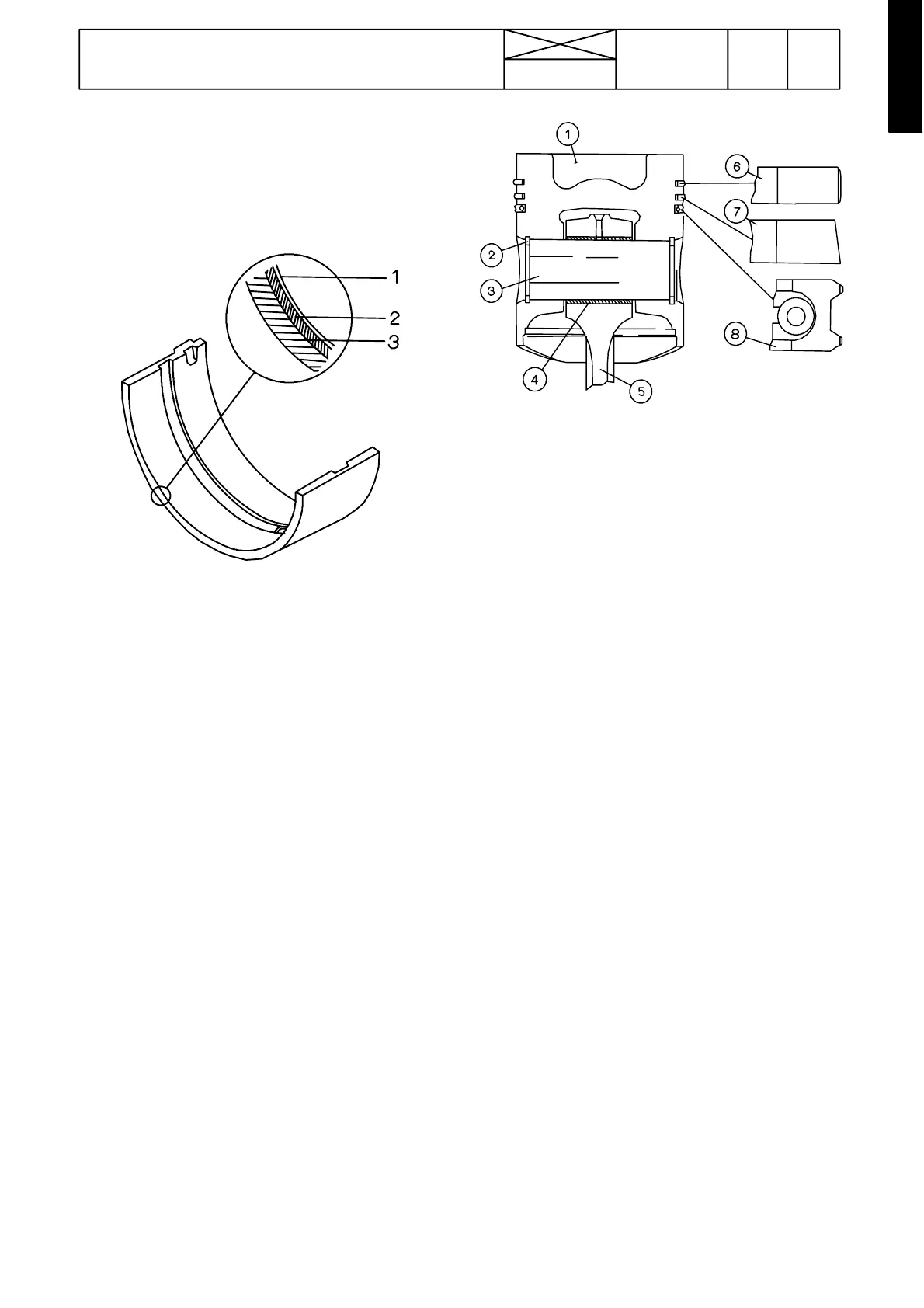

Piston

1. Combustion chamber

2. Circlip

3. Piston pin

4. Bearing bushing

5. Connecting rod

6. Chromed compression ring

7. Compression ring

8. Spring loaded oil control ring chromed slide surfaces

The pistonis made of an eutectic aluminium alloy.In theupper

part of the piston there is a combustion chamber (1). The

shape of the chamber is intended to maximise the mixture of

air and fuel. The number of piston rings is three, of which the

upper (6) has a barrel face, chromed slide surface. The sec-

ond compression ring (7) is tapered at an angle of 1,5˚,and

the third ring is a spring loaded oil control ring (8). The piston

pin (3) has a close tolerance in the piston and a floating fit in

the connecting rod.

Loading...

Loading...